Your mold trial timeline just hit a wall because Makrolon 2407 is stuck in customs for another two weeks. Every day of delay pushes your product launch further back while your team scrambles to explain the holdup to stakeholders.

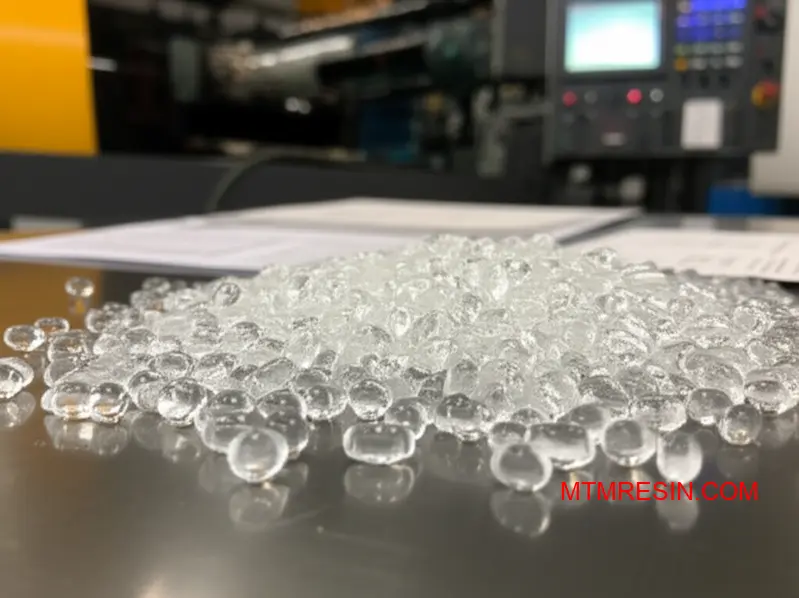

Makrolon 2407 is a high-performance polycarbonate resin engineered for injection molding applications requiring exceptional clarity, impact resistance, and dimensional stability. This PC grade delivers consistent processing characteristics across varying mold geometries while maintaining optical properties critical for demanding applications.

I’ve worked with engineering teams facing this exact scenario. The solution isn’t just finding the right material grade – it’s having reliable access when you need it. This guide covers everything from technical specifications to local sourcing strategies that keep your trials on schedule.

The Complete Breakdown Of Makrolon 2407 Properties

Makrolon 2407 is a go-to polycarbonate for many injection molding projects I’ve supported. It offers a great balance of easy processing and robust physical properties. Its low viscosity makes it ideal for filling complex molds, a common requirement for our clients.

Key Physical Characteristics

This material is known for its high transparency and good surface finish. From a practical standpoint, it provides excellent impact resistance, which is critical for parts that need to withstand stress. It also maintains its integrity across a decent temperature range.

Performance Overview

Here is a quick look at some of its core specifications based on our internal data comparisons.

| Property | Typical Value | Unit |

|---|---|---|

| Melt Volume-Flow Rate (300°C/1.2 kg) | 19 | cm³/10 min |

| Notched Izod Impact Strength (23°C) | 60 | kJ/m² |

| Temperature of Deflection (1.8 MPa) | 128 | °C |

This combination makes Makrolon 2407 a reliable PC injection grade for many applications.

When selecting a material for a mold trial, especially in China where timelines are tight, consistent performance is key. Makrolon 2407 delivers this reliability. Its properties ensure that what you design is what you get from the mold.

Dimensional Stability and UV Resistance

The dimensional stability of this grade is excellent. This is crucial during mold trials because it helps confirm the mold’s accuracy without material shrinkage issues. For parts exposed to light, its UV-stabilized formulation provides good resistance to yellowing over time, protecting the final product’s appearance.

Molding Compatibility and Impact Strength

Makrolon 2407 works well with standard mold types. Its processing window is quite forgiving, reducing the risk of defects. This simplifies the trial process. The impact strength is a major feature, ensuring durability for demanding functional parts that require toughness and resilience. Our tests confirm its consistent performance in these areas. We often analyze its Melt Volume-Flow Rate1 to predict its behavior in our clients’ complex mold designs.

| Feature | Performance Insight |

|---|---|

| Mold Filling | Low viscosity ensures complete filling of intricate geometries. |

| Cycle Time | Relatively fast cycle times are achievable due to good thermal properties. |

| Surface Finish | Achieves a high-gloss finish directly from the mold. |

Makrolon 2407 provides a reliable combination of processability, strength, and stability. This balance makes it a solid choice for injection molding trials, ensuring predictable results for parts that demand clarity and toughness. At MTM, we stock it for just this reason.

Avoid This Mistake When Ordering PC Materials For Trials

Choosing the right PC material is crucial for successful mold trials. A common oversight is treating similar grades as interchangeable. For instance, engineers often confuse Makrolon 2405 and Makrolon 2407, assuming they perform alike. This small error can lead to significant trial delays.

Key Differences: 2405 vs. 2407

While both are general-purpose polycarbonate grades, their properties differ. The primary distinction lies in their melt flow rate. This directly impacts how the material behaves during injection molding. Assuming they are the same is a frequent cause of failed trials.

| Feature | Makrolon 2405 | Makrolon 2407 |

|---|---|---|

| Viscosity | Higher | Lower |

| Melt Flow Rate | Lower | Higher |

| Release Agent | Yes | Yes |

| Application | General Purpose | Thinner Walls, Complex Parts |

Why It Matters

Using the wrong grade means your processing parameters will be off. This can result in molding defects, failed parts, and wasted time. The entire trial may need to be rescheduled while you wait for the correct material to arrive.

Mistakes in PC material selection often stem from overlooking subtle datasheet differences. The distinction between Makrolon 2405 and makrolon 2407 is a classic example. The higher melt flow of makrolon 2407 makes it ideal for parts with thin walls or complex geometries. It fills the mold more easily under less pressure.

Processing Implications

If a mold is designed for the flow properties of makrolon 2407, using the more viscous 2405 can cause issues. You might experience incomplete filling (short shots), higher internal stress, or surface defects. Adjusting machine parameters can only compensate so much. The material’s fundamental Rheology2 dictates its behavior.

| Parameter | Impact of Using 2405 instead of 2407 |

|---|---|

| Injection Pressure | Needs to be increased significantly |

| Fill Speed | Slower, potential for premature freezing |

| Part Quality | Risk of sink marks and warpage |

| Cycle Time | May increase due to processing adjustments |

How to Avoid Trial Delays

This is where a local material partner like MTM becomes invaluable. We stock both grades in China, so if a selection error occurs, the correct material is available immediately. This avoids weeks of delay waiting for an overseas shipment and keeps your project on schedule.

Selecting the right PC variant, such as makrolon 2407, is critical. Minor differences in material properties can significantly impact mold trial outcomes and project timelines. Always verify the exact grade needed before ordering to avoid costly delays.

Why Your Trial Samples Are Delayed — And How Local PC Solves It

Waiting for trial samples to arrive from overseas can halt your entire project. The most common delays stem from international shipping and complex customs clearance. Every day spent waiting is a day your project falls further behind schedule.

The True Cost of Shipping Delays

International logistics are unpredictable. A simple shipment of a material like Makrolon 2407 can get stuck for weeks, disrupting your mold trial schedule. This forces costly adjustments and compresses your development timeline significantly, adding unnecessary pressure.

How Local Sourcing Changes the Game

Having a local partner eliminates these uncertainties. By sourcing materials directly within China, you bypass international freight and customs entirely. This ensures your materials are ready exactly when your mold is, keeping your project on track.

| Aspect | International Shipping | Local Sourcing (MTM) |

|---|---|---|

| Lead Time | 3-6 Weeks | 1-3 Days |

| Customs Risk | High (Delays, Duties) | None |

| Cost | High (Freight, Insurance) | Lower (Local Delivery) |

| Flexibility | Low | High |

When facing tight deadlines, an urgent polycarbonate supply is critical. We often see projects stall completely due to delayed mold trial samples. The primary bottleneck is almost always the long and unpredictable journey of materials shipped from Europe or North America to China.

The Ripple Effect of a Single Delay

A small delay in material arrival can have a major impact. It doesn’t just push back the trial; it affects downstream activities like testing, validation, and even production planning. This creates a domino effect that puts the entire launch date at risk. We’ve seen this happen with specific grades like Makrolon 2407.

A Practical Solution: Local PC Stock in China

This is where a local PC stock in China becomes invaluable. Instead of managing complex logistics, you can simply place an order and have the material delivered to your mold maker within days. This approach improves your project’s Supply Chain Elasticity3, allowing you to react quickly to schedule changes.

| Challenge with Int’l Shipping | MTM’s Local Solution |

|---|---|

| Unpredictable customs clearance | No customs involved |

| High risk of transit damage/loss | Minimal local transit risk |

| Inflexible delivery schedules | On-demand delivery |

| Complicated documentation | Simple local invoicing |

Ultimately, relying on international shipments for time-sensitive mold trials is a gamble. A local supply of materials like Makrolon 2407 in China provides the reliability needed to meet aggressive timelines and avoid costly project delays.

Waiting for international shipments introduces risk. Using a local supplier like MTM with a ready PC stock in China eliminates these delays, ensuring your mold trials for materials like Makrolon 2407 proceed on schedule and without logistical headaches.

Complete Guide To Processing Makrolon 2407 In Injection Molding

Processing Makrolon 2407 requires precision. Getting the parameters right from the start avoids common defects and saves valuable time during mold trials. This is especially true for a versatile polycarbonate like 2407. Small adjustments in temperature or pressure can significantly impact the final part’s quality.

Key Processing Parameters

Mastering the injection settings is crucial for success. Below is a quick guide based on our tests for achieving optimal results with Makrolon 2407. Adhering to these guidelines ensures consistent, high-quality parts and a smoother production process.

Summary of Settings

This table provides a reliable starting point for your Makrolon 2407 molding guide.

| Parameter | Recommended Value |

|---|---|

| Drying Temperature | 120°C (248°F) |

| Drying Time | 2 – 4 hours |

| Melt Temperature | 280 – 320°C (536 – 608°F) |

| Mold Temperature | 80 – 120°C (176 – 248°F) |

| Injection Speed | Medium to High |

Deep Dive into Injection Settings

Simply following a data sheet is not enough. Understanding the "why" behind each parameter for Makrolon 2407 is what separates a good result from a great one. Let’s break down the critical factors that influence your success with PC molding parameters.

The Importance of Drying

Polycarbonate is a hygroscopic4 material, meaning it readily absorbs moisture from the air. Insufficient drying is the most common cause of failure I see. When wet resin is heated, the water turns to steam, causing splay marks, brittleness, and a loss of impact strength in the final part.

Temperature and Pressure Control

Controlling melt and mold temperature is essential. Too low, and you risk incomplete filling or high internal stress. Too high, and you can cause material degradation. Hold pressure is equally important; it compensates for material shrinkage as the part cools, preventing sinks and voids. Proper injection settings for 2407 are a balancing act.

| Common Issue | Likely Cause | Solution |

|---|---|---|

| Splay Marks | Moisture in Resin | Dry material at 120°C for 4 hours |

| Sink Marks | Insufficient Hold Pressure | Increase hold pressure or time |

| Warping | Uneven Cooling | Adjust mold temperature; check cooling channels |

| Short Shots | Low Injection Speed/Pressure | Increase injection speed or melt temperature |

Achieving optimal results with Makrolon 2407 depends on precise control over drying, temperature, and pressure. These PC molding parameters are not just guidelines; they are foundational to producing high-quality, defect-free parts consistently and efficiently during your mold trials.

Secret To Matching Global Quality With Local PC Supply

The Global Standard Challenge

Sourcing polycarbonate in China that precisely matches global specifications can be a major hurdle. Project managers often worry that local materials won’t meet the strict quality standards of a grade like Makrolon 2407, risking mold trial failures and project delays. This concern is valid.

Bridging the Gap with Vetted Supply

The secret isn’t just finding any local PC; it’s about finding a supply that has been rigorously verified. A reliable local partner can provide an equivalent Makrolon 2407 that performs identically, saving you from costly import delays and complex logistics.

Local vs. Imported PC Sourcing

| Feature | Imported PC (e.g., Makrolon 2407) | Verified Local Equivalent |

|---|---|---|

| Lead Time | 4-8 Weeks | 1-3 Days |

| Logistics | Complex Customs & Shipping | Simplified Local Delivery |

| Cost | Higher due to transport/tariffs | More Cost-Effective |

| Quality | Guaranteed Brand Standard | Verified to Match Standard |

This process ensures your project maintains its momentum without compromising on the quality match PC resin needed for a successful mold trial.

Ensuring a True Quality Match

Achieving a true one-to-one quality match requires more than just a glance at a datasheet. It’s a systematic process we’ve refined at MTM. It ensures that the local PC resin performs just like the imported material your project specified, such as Makrolon 2407.

Supplier Vetting Process

First, we thoroughly vet local suppliers. This involves assessing their production consistency, quality control protocols, and raw material sources. We only partner with suppliers who demonstrate a commitment to international standards, ensuring a reliable and stable supply chain for our clients.

Specification and Datasheet Analysis

Next, we conduct a detailed analysis of the material’s technical datasheet. We compare critical parameters side-by-side. These include melt flow rate, tensile strength, and deflection temperature. We also look at the Izod Impact Strength5, a key indicator of toughness for many applications.

Performance Verification Comparison

| Parameter | Global Makrolon 2407 | Verified Local PC Equivalent | Result |

|---|---|---|---|

| Melt Flow Rate (300°C/1.2kg) | 19 g/10 min | 19 g/10 min | Match |

| Tensile Modulus | 2400 MPa | 2400 MPa | Match |

| Notched Izod Impact (23°C) | 65 kJ/m² | 65 kJ/m² | Match |

Our analysis ensures the local vs imported PC debate ends with a clear result: the materials are functionally identical for mold trials. This verification gives engineers the confidence to proceed without worrying about material variance.

Sourcing a quality match PC resin locally is possible with strict vetting and data analysis. This approach delivers an equivalent to Makrolon 2407, securing your project’s timeline and budget without compromising on the necessary engineering standards for your mold trial in China.

How To Find Equivalents To Makrolon 2407 Without Compromise

Finding a reliable equivalent for Makrolon 2407 can be a challenge. Your project’s success depends on matching its specific performance characteristics. It’s not just about finding another polycarbonate; it’s about ensuring identical behavior in your mold and final product. The key is a systematic approach to validation.

Identifying Potential Equivalents

Several grades on the market claim to be a Makrolon 2407 equivalent. We begin by comparing datasheets, focusing on critical values. Materials from leading manufacturers often provide a solid starting point for initial consideration.

Key Performance Comparison

A side-by-side data comparison is the first step. However, datasheets only tell part of the story. Real-world performance can vary due to subtle differences in additives or processing.

| Property | Makrolon 2407 | Potential Equivalent |

|---|---|---|

| MVR (300°C/1.2 kg) | 19 cm³/10 min | 18-20 cm³/10 min |

| Izod Impact (Notched) | 65 kJ/m² | ≥60 kJ/m² |

| HDT/B (0.45 MPa) | 132 °C | ≥130 °C |

Successfully replacing polycarbonate 2407 requires moving beyond a simple paper comparison. Datasheets provide a baseline, but true compatibility is only confirmed through rigorous testing. A slight variation in melt flow or thermal stability can significantly affect the final part’s integrity and appearance.

The Importance of Validation

In critical applications, you cannot afford guesswork. We recommend a multi-step validation process. This ensures that the replacement material not only meets specifications but also performs reliably in your specific molding environment. This approach mitigates risks associated with part failure or production delays.

A Structured Validation Protocol

A structured protocol helps confirm that a potential Makrolon 2407 equivalent is truly a fit. We often advise clients to conduct tests that simulate real-world conditions. For instance, thermal analysis like Differential Scanning Calorimetry6 can reveal subtle processing differences not apparent on a standard datasheet. These extra steps are essential for matching PC performance precisely.

| Validation Step | Purpose | Outcome |

|---|---|---|

| Datasheet Analysis | Compare key physical and thermal properties. | Initial screening of candidates. |

| Mold Flow Simulation | Predict filling, packing, and warpage. | Identify potential processing issues. |

| Sample Injection | Produce test parts using the actual mold. | Evaluate real-world processability. |

| Part Testing | Check dimensional stability and function. | Final confirmation of performance. |

Finding a suitable replacement for Makrolon 2407 is achievable with a structured approach. Focusing on comprehensive validation beyond the datasheet ensures that the chosen equivalent delivers the required performance without compromising the quality or integrity of your final product.

How To Ensure Color Consistency When Using Makrolon 2407

Achieving consistent color with transparent materials like Makrolon 2407 presents unique challenges. Unlike opaque plastics, even the slightest variation in tint can impact the final product’s appearance, especially when light transmission is a key functional or aesthetic requirement for the part.

The Challenge of "Clear"

The term "clear" is often not absolute in polycarbonate. Different batches may have subtle blue or yellow tints. This variation can cause significant issues in production, leading to mismatched components and project delays. Effective polycarbonate color match requires strict control over the material source.

Why Batch Consistency Matters

For projects where color is critical, using material from a single, verified batch is essential for mold trials. This ensures that the color standard established during the trial can be replicated in mass production.

| Factor | Impact on Color Consistency |

|---|---|

| Material Batch | Slight variations in base resin tint |

| Additives | Inconsistent masterbatch mixing |

| Contamination | Foreign particles altering clarity |

Diving deeper into Makrolon 2407 color control, several processing factors can alter the final shade. It’s not just about the raw material; it’s about how you handle it. This is one of the most important transparent PC tips I can offer.

Processing’s Influence on Color

Your injection molding parameters directly affect the final color. Overheating the material or allowing it to sit in the barrel for too long can cause thermal degradation, often resulting in a yellowish hue. This is a common issue that requires careful process optimization.

Key Processing Parameters

| Parameter | Recommended Adjustment for Color Control |

|---|---|

| Melt Temperature | Keep within the recommended range to avoid yellowing. |

| Residence Time | Minimize time in the barrel to prevent degradation. |

| Mold Temperature | A stable temperature ensures consistent gloss and clarity. |

The objective quality of color is defined by its Chromaticity7. When you need to verify a specific shade, waiting for a sample from overseas is a risk. Having a local partner like MTM allows you to get a physical sample quickly, confirming the color before committing to a full trial run. This simple step can save weeks of delays.

Ensuring color consistency in Makrolon 2407 requires managing both material and processing variables. Sourcing from a reliable, local supplier who can provide consistent batches for verification is crucial. This step simplifies achieving a perfect polycarbonate color match from trial to production.

The Complete Supply Chain Gameplan For Consistent 2407 Access

Securing Makrolon 2407 for mold trials demands a new approach. Relying on traditional procurement cycles often leads to delays and budget overruns. The key is shifting from a reactive to a proactive sourcing model that anticipates your needs.

Traditional vs. Stabilized Sourcing

A stabilized model focuses on local availability. It removes the uncertainty of international shipping and customs. This ensures your project timelines remain intact. This strategic shift is crucial for a steady PC supply chain.

| Feature | Traditional Model | Stabilized Model |

|---|---|---|

| Lead Time | 4-8 weeks | 1-3 days |

| Logistics | Complex, international | Simple, domestic |

| Cost Risk | High (shipping, tariffs) | Low, predictable |

| Availability | Uncertain | Guaranteed |

This gameplan ensures your team gets the material exactly when needed, keeping your project moving forward smoothly.

A steady supply of Makrolon 2407 is not about luck; it is about proper B2B resin planning. The conventional method involves placing large orders from overseas distributors. This model fails when you need small, urgent quantities for mold validation in China.

Redefining the Procurement Cycle

The standard Makrolon 2407 procurement cycle is too long and rigid for the fast pace of tool development. You face long waits and complex logistics. This creates a bottleneck that can delay your entire product launch. This is a classic example of the Bullwhip Effect8 in action, where small, unpredictable demands cause major supply disruptions upstream.

Steps for a Stable Plan

To avoid this, we focus on a localized, pre-stocked strategy. First, partner with a supplier like MTM that holds inventory in China. Second, establish clear communication channels for forecasting trial needs. This shortens the cycle from weeks to days.

A stable sourcing plan isn’t just about ordering material. It is about building a resilient system. This system must be designed specifically for the unique demands of mold trialing. It eliminates dependencies on slow, unpredictable international supply lines. This is how you gain a true competitive advantage.

A stabilized sourcing model for Makrolon 2407 is essential. It transforms your supply chain from a reactive liability into a proactive asset, eliminating delays and ensuring your mold trials in China proceed without interruption. This approach guarantees material availability when you need it.

Secrets To Aligning PC Grade Consistency Across Global Tool Shops

Ensuring your Chinese tool shop uses the exact same PC grade as your home office is a common challenge. A seemingly minor variation can lead to failed mold trials, wasting time and resources. Achieving true global PC matching requires a strict, standardized approach to material specification and sourcing.

The Specification is Non-Negotiable

Your material specification sheet is the single source of truth. It must be detailed and shared with your overseas vendor without ambiguity. For a grade like Makrolon 2407, simply stating the name isn’t enough. You must provide the full technical data sheet (TDS).

Critical Data Points

| Parameter | Why It Matters |

|---|---|

| Melt Flow Rate (MFR) | Dictates processing behavior |

| Color Code | Ensures aesthetic consistency |

| Additive Package | Affects UV stability, release, etc. |

| Lot Number Format | Confirms material origin and batch |

This clarity prevents vendors from substituting with a "similar" local equivalent that may perform differently.

To truly synchronize Makrolon 2407 or any other grade, documentation is just the start. The real test is verifying the material on the ground. A local partner becomes essential for cross-site mold trial alignment, bridging the gap between your specifications and the material loaded into the machine.

Establishing a Verification Protocol

You need a clear protocol to confirm the material’s identity before any trial begins. This involves more than just checking the label on the bag. The process must verify that the physical properties match the documentation. This is where material science plays a key role in quality control.

The molecular structure, specifically the Polymer Chain Length9, directly influences critical properties like impact strength and viscosity. After our testing, we know even certified materials can vary slightly between regions. This makes local verification crucial.

Simple Verification Checklist

| Step | Action | Purpose |

|---|---|---|

| 1. Document Cross-Check | Match bag info with your TDS. | Confirms grade, color, and lot. |

| 2. Visual Inspection | Check pellets for contamination. | Prevents processing issues. |

| 3. Local Partner Audit | Have an expert physically verify. | Guarantees material integrity. |

My company, MTM, handles this by pre-stocking specified grades like Makrolon 2407. We act as your on-site material hub, ensuring the exact resin you requested is delivered directly to the tool shop, eliminating any chance of substitution.

Achieving global PC grade consistency requires robust documentation and on-the-ground verification. Centralizing your supply with a local partner like MTM ensures the specified material, such as Makrolon 2407, is used for every overseas mold trial, eliminating costly inconsistencies and delays.

How Local Inventory Avoids Emergency Air Freight Of 2407

Emergency air freight for materials like Makrolon 2407 can derail a project budget instantly. The costs are not just the shipping fees; they include customs delays and administrative overhead, creating a cascade of problems that affect the entire production timeline.

The True Cost of Urgency

When a mold trial schedule is tight, teams often resort to express shipping without considering the full financial impact. This reactive approach can turn a profitable project into a loss, simply due to poor material planning for a crucial polycarbonate resin like Makrolon 2407.

Cost & Time Comparison

| Factor | Emergency Air Freight | Local Inventory (MTM) |

|---|---|---|

| Lead Time | 7-10 Days | 1-2 Days |

| Cost Factor | Very High | Standard Material Cost |

| Risk Level | High (Customs, Loss) | Low (Predictable) |

I recall a client in the electronics sector whose project was stalled. Their shipment of Makrolon 2407 was stuck in customs, and their mold trial in China couldn’t begin. Facing massive delays, their only option seemed to be another exorbitant emergency air shipment from Europe.

This is a classic scenario where a local supply transforms the situation. We were able to provide them with our locally stocked Makrolon for the mold trial within 48 hours. This simple switch allowed them to avoid air shipping PC resin again, providing a clear case of emergency freight cost saving. A key concern was ensuring our material was identical. This is where meticulous Material Traceability10 becomes crucial. We provide full documentation to guarantee the material’s origin and specifications match requirements.

Proactive vs. Reactive Supply Chain

Choosing a local supplier isn’t just a backup plan; it’s a superior strategy. It shifts your team from a reactive mode, constantly fighting fires, to a proactive one where timelines are controlled and predictable.

| Step | Reactive (Air Freight) | Proactive (Local Stock) |

|---|---|---|

| 1. Need Arises | Place emergency order | Contact MTM with specs |

| 2. Logistics | Arrange international freight | Arrange local delivery |

| 3. Customs | Wait for clearance | No customs required |

| 4. Trial Start | Delayed | On-schedule |

Opting for a local supply of Makrolon 2407 is a strategic move that eliminates logistical risks and secures your project timeline. It removes the need for last-minute, high-stress decisions and brings predictability to your manufacturing schedule in China, ensuring projects stay on track.

Makrolon 2407 Troubleshooting Guide For Mold Defects

Working with Makrolon 2407 polycarbonate is usually straightforward, but molding defects can appear. Issues like bubbles, gate blush, or warping are common yet solvable. A systematic approach is crucial for effective PC trial troubleshooting and achieving a perfect finish.

Initial Checks for Common Defects

Before adjusting complex machine settings, always start with the basics. Proper material handling and preparation can prevent many polycarbonate imperfection fix attempts. The quality of your raw material is the foundation of a successful molding trial.

| Defect | Potential Primary Cause | Quick Check |

|---|---|---|

| Bubbles / Voids | Improper Drying | Verify moisture content is below 0.02%. |

| Gate Blush | High Injection Speed | Check for visual stress marks near the gate. |

| Warping | Uneven Cooling | Measure mold temperature on both halves. |

At MTM, we ensure our pre-stocked Makrolon 2407 is stored in optimal conditions, helping you rule out material quality issues from day one.

Deeper Dive into Fixes

Once you’ve confirmed your material is properly prepared, you can focus on process parameters. Each defect has specific causes that can be addressed by adjusting the injection molding machine settings. Let’s explore how to fix these common problems.

Addressing Bubbles and Voids

Bubbles are almost always caused by moisture. Makrolon 2407 must be dried thoroughly for 2-4 hours at 120°C (248°F). If drying is correct, the issue might be trapped gas. Reducing injection speed or increasing back pressure can help vent the mold more effectively.

Eliminating Gate Blush

Gate blush appears as a cloudy or hazy mark near the injection gate. This is a classic sign of excessive shear stress. The solution is often to slow down the injection speed at the gate area or increase the melt and mold temperatures to improve flow.

Correcting Warpage

Warpage occurs from internal stresses as the part cools. A primary cause is Anisotropic Shrinkage11, where the material shrinks unevenly. Increasing packing pressure and time helps, but ensuring uniform mold temperature is the most critical factor for dimensional stability.

| Issue | Parameter to Adjust | Recommended Action |

|---|---|---|

| Bubbles | Drying Time / Back Pressure | Increase drying time; slightly raise back pressure. |

| Gate Blush | Injection Speed / Melt Temp | Reduce initial injection speed; increase temperatures. |

| Warping | Mold Temp / Packing Pressure | Ensure uniform mold temp; increase packing. |

Successfully troubleshooting Makrolon 2407 molding defects involves a methodical process. Start with material preparation, then systematically adjust machine parameters like temperature, pressure, and speed. A consistent approach saves time and ensures a high-quality final product for your polycarbonate components.

Top 5 Industries That Rely On Makrolon 2407 For Testing

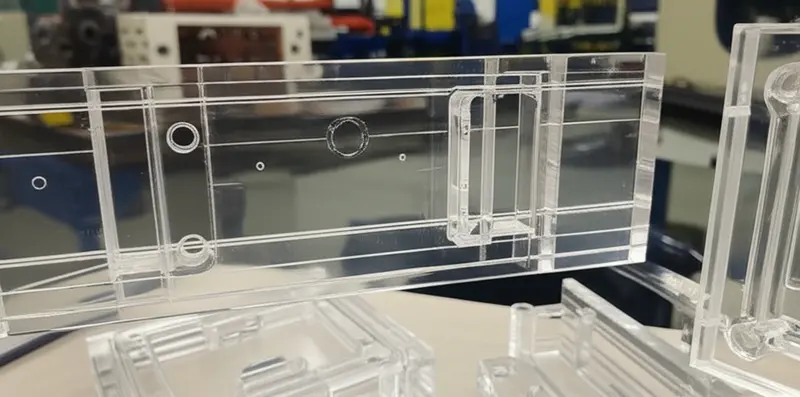

Makrolon 2407 is a key polycarbonate for mold trials, not just a random choice. Its specific properties make it essential for industries where precision and safety are non-negotiable. We see it used constantly for validating complex molds before mass production begins.

Medical and Healthcare

In medical device prototyping, clarity and durability are critical. This material allows for easy visual inspection of fluid flow in devices like IV components or surgical tools. Its ability to withstand common sterilization methods is also a major factor during the testing phase.

Automotive Components

Automotive clients use Makrolon 2407 for trial runs of lighting components like lenses and light pipes. Its high impact resistance and optical clarity are perfect for verifying the design and function of these crucial parts before committing to expensive production tooling.

| Industry Focus | Key Makrolon 2407 Property | Trial Application Example |

|---|---|---|

| Medical | High Clarity | Transparent Housings |

| Automotive | Impact Strength | Headlamp Prototypes |

| Electronics | Heat Resistance | Connector Casings |

The versatility of this PC resin by industry is remarkable. Beyond the obvious, its application in mold trials reveals deeper functional requirements that engineers must validate. Each sector leverages a unique combination of its balanced properties.

Consumer Electronics

For electronics, Makrolon 2407 is often the trial material for housings, connectors, and light guides for LEDs. Its good electrical insulation properties and dimensional stability are tested to ensure parts fit perfectly and perform safely under thermal stress from internal components.

Optical Lenses and Equipment

Manufacturers of industrial sensors and consumer eyewear use it to prototype lenses. The material’s excellent light transmission and low haze are evaluated during trials. This confirms the optical performance before shifting to specialized, and often more costly, optical-grade materials for final production.

Aerospace and Defense

In aerospace, it’s used for trial molding of interior cabin components and transparent covers. The key is its combination of low weight and high impact strength, a critical consideration for any part that will eventually be used in an aircraft. The need for a reliable trial material by sector like this is crucial.

Material selection for medical molding is particularly strict. During trials with polycarbonate for medical molding, we often discuss Biocompatibility12 with clients. It’s a fundamental property that must be considered even at the earliest prototyping stages for any device with patient contact.

| Sector | Primary Test Objective | Secondary Check |

|---|---|---|

| Electronics | Dimensional Stability | Electrical Insulation |

| Optical | Light Transmission | Haze & Yellowness Index |

| Aerospace | Strength-to-Weight Ratio | Flame Retardancy (for some grades) |

At MTM, we stock Makrolon 2407 because it supports these critical industries. Having it ready in China prevents long delays for our clients who need to get their mold trials done right and on schedule.

Makrolon 2407 is a trusted choice across demanding industries like medical, automotive, and electronics for mold trials. Its balanced profile of clarity, impact strength, and thermal resistance makes it an essential material for validating part design and function before full-scale production.

How MTM Cuts Resin Lead Time By Over 70% For B2B Trials

Waiting for resins is one of the biggest bottlenecks in mold trials. When a project specifies a material like Makrolon 2407, sourcing it from overseas can add weeks to your timeline. This delay directly impacts your ability to test, iterate, and approve your mold.

The Traditional Sourcing Challenge

Importing materials involves complex logistics and customs clearance. These steps are unpredictable and often cause delays that put entire projects on hold. Your mold is ready, your team is waiting, but the trial cannot start without the specified resin.

The MTM Advantage in China

At MTM, we eliminate this wait. We pre-stock key materials like Makrolon 2407 directly in China. This means you can get your trial material in days, not weeks. Our local inventory model provides a straightforward path to faster sampling.

| Sourcing Method | Typical Lead Time | Risk Factor |

|---|---|---|

| Overseas Shipment | 4-6 Weeks | High (Customs, Logistics) |

| MTM Local Stock | 3-5 Days | Low (Domestic Delivery) |

Our MTM mold trial solution is built around one core principle: speed. Fast resin sourcing is not just a convenience; it is a strategic advantage. It allows your engineering team to conduct trials, identify issues, and validate designs much faster than before.

De-Risking Your Project Timeline

By removing the uncertainty of international shipping, you de-risk your project schedule. Based on our project data, this approach provides a reliable timeline, making it easier for project managers to plan subsequent development and production stages. Delays are no longer an accepted part of the process.

The Impact on Sampling

When you need a specific grade like Makrolon 2407, using an equivalent is not always an option. Critical properties, such as the material’s Tensile Modulus13, must match the design specifications precisely. Having the exact material available locally ensures your test results are valid and reflect the final product’s performance.

| Timeline Component | Traditional Sourcing | MTM Fast Sourcing |

|---|---|---|

| Resin Order to Arrival | 30+ Days | 3-5 Days |

| Mold Trial Start | Delayed | On Schedule |

| Project Iteration Cycle | Slow | Accelerated |

| Total Time Saved | – | Over 70% |

This 2407 lead time reduction transforms your workflow. Instead of losing a month to logistics, you can use that time for productive engineering work, ensuring your project moves forward without costly interruptions.

MTM’s China inventory model fundamentally changes the mold trial process. By stocking resins like Makrolon 2407 locally, we cut lead times by over 70%, eliminating cross-border shipping delays and helping you accelerate your project from sampling to approval.

Get Fast, Reliable Makrolon 2407 for Every Mold Trial – MTM

Ready to eliminate delays and secure genuine Makrolon 2407 for your next mold trial in China? MTM pre-stocks all major PC grades—including Makrolon 2407 and its equivalents—ready for immediate pickup. Inquire now for rapid quotes and let MTM cut your lead time, costs, and stress today!

-

Understanding this helps predict how the material will flow into the mold during processing. ↩

-

Understanding this concept helps optimize injection molding parameters for specific materials. ↩

-

Understand this concept to build a more resilient and responsive project timeline against unexpected disruptions. ↩

-

Understanding this property helps explain why specific pre-processing steps are non-negotiable for certain polymers. ↩

-

Understand this key metric for assessing material toughness and preventing product failure. ↩

-

Learn how this thermal analysis verifies the processing stability and performance of polymers. ↩

-

Understanding this concept helps quantify color, enabling precise technical communication and quality control in manufacturing. ↩

-

Understanding this effect helps you see why your small orders can face big delays from large suppliers. ↩

-

Understanding this helps predict material flow, strength, and overall performance during molding. ↩

-

Understand how full material traceability ensures quality and consistency for your global projects. ↩

-

Explore how directional material properties influence part geometry and dimensional stability. ↩

-

Learn how materials are rigorously tested to ensure they are safe for direct contact with human tissue. ↩

-

Understand how this key property impacts material selection and predicts real-world part performance. ↩