Finding the right Makrolon supplier can make or break your project timeline. When your mold trials depend on authentic material delivered on schedule, supplier delays or counterfeit resins can cost you weeks of development time and thousands in rework expenses.

The best Makrolon suppliers combine authentic material certification, local stock availability, and proven delivery reliability to support your engineering projects without delays or quality compromises.

This guide covers everything from supplier verification to import logistics, helping you avoid the common pitfalls that slow down procurement teams. You’ll discover proven strategies for evaluating suppliers and securing consistent material quality for your trials.

The Ultimate Checklist For Choosing A Reliable Makrolon Supplier

Finding the right Makrolon supplier is crucial, especially for time-sensitive mold trials in China. Your choice impacts project timelines and final part quality. A reliable partner offers more than just material; they provide confidence and efficiency when you need it most.

Verifying Authenticity and Traceability

Ensure any potential supplier provides complete material datasheets and certificates of analysis. This guarantees you are using genuine Makrolon, preventing costly failures. Among the best suppliers of Makrolon, transparency is a standard practice, not an added service.

Assessing Stock Availability

Immediate availability is non-negotiable for mold trials. A supplier with local stock, like we maintain at MTM, eliminates cross-border shipping delays and customs issues. This is a key point in my Makrolon supplier checklist.

Key Supplier Evaluation Points

| Criteria | Ideal Response | Red Flag |

|---|---|---|

| Material Authenticity | Provides full documentation | Vague or missing paperwork |

| Local Stock | Confirms ready-to-ship inventory | Long lead times for delivery |

| Technical Support | Offers expert advice | Cannot answer technical questions |

| Delivery Speed | Can deliver within 1-2 days | Quotes international shipping times |

When you evaluate how to choose a Makrolon supplier, look past the per-kilogram price. The true cost includes potential project delays, shipping uncertainties, and the risk of using non-compliant materials. A cheap offer from a distant supplier can quickly become expensive.

Beyond the Price Tag: Hidden Costs

I have seen projects stall for weeks waiting for a material shipment to clear customs. Choosing a reliable polycarbonate vendor with a local presence in China mitigates these risks entirely, turning a potential bottleneck into a smooth process. This is a critical advantage.

Technical Competence and Support

A great supplier understands the material’s technical nuances. They can advise on processing parameters and potential issues related to properties like Birefringence1. This level of support is invaluable during the critical mold trial phase, ensuring part performance meets design specifications.

Comparing Supplier Types

| Feature | Reliable Partner (e.g., MTM) | Transactional Seller |

|---|---|---|

| Inventory Strategy | Pre-stocked locally in China | Ships from overseas |

| Focus | Project success and speed | Selling units |

| Value Add | Technical support, problem-solving | Basic order fulfillment |

| Communication | Direct and responsive | Multiple intermediaries |

Choosing the right Makrolon supplier is a strategic decision. It’s about securing a partner who guarantees material authenticity, offers local availability to prevent delays, and provides the technical support needed to ensure your mold trials succeed on the first attempt.

Secrets To Cutting Lead Times In Makrolon Procurement

Procuring Makrolon polycarbonate for mold trials in China often involves frustrating delays. When materials are shipped from overseas, projects can stall for weeks waiting on logistics and customs clearance. This waiting game directly impacts your project timeline and budget, creating unnecessary stress.

The Problem with International Shipping

Relying on international shipments introduces multiple variables that extend lead times. These delays are not just about the time spent in transit; they also include customs processing, which can be unpredictable and complex. Every day spent waiting is a day your mold isn’t being tested.

The Local Sourcing Advantage

The key to achieving Makrolon fast delivery is shifting your procurement strategy. By partnering with a local Makrolon supplier in China, you bypass international shipping entirely. This move drastically cuts down your material acquisition timeline from weeks to mere days.

To truly reduce lead time for Makrolon, you must look beyond the material’s price tag and consider the total cost of delays. International procurement might seem straightforward, but hidden complexities often emerge. Customs clearance, for instance, is a significant bottleneck that many teams underestimate.

Navigating Customs and Logistics

Every international shipment requires precise documentation. A small error in the paperwork, especially with the Harmonized System (HS) Code2, can cause your material to be held at the port for an indefinite period. This is where partnering with the best suppliers of makrolon locally makes a difference. A local partner handles all these regulatory hurdles.

At MTM, we pre-stock certified Makrolon grades within China. This means the material has already cleared customs and is ready for immediate dispatch. This eliminates the uncertainty and delays associated with cross-border logistics. Your team can focus on the mold trial, not on tracking shipments.

Lead Time Comparison

| Procurement Method | Typical Lead Time | Customs Risk |

|---|---|---|

| International Shipment | 4-8 Weeks | High |

| Local Pre-Stocked Supplier | 1-3 Days | None |

This comparison clearly shows how a local supplier model transforms your procurement timeline. It turns a lengthy, unpredictable process into a fast and reliable one.

Partnering with a local, pre-stocked supplier like MTM in China is the most effective way to cut Makrolon lead times. This strategy eliminates international shipping delays and customs risks, ensuring your mold trial materials arrive exactly when you need them.

Insider Guide To Spotting Genuine vs. Counterfeit Makrolon Resin

Identifying authentic Makrolon resin is crucial for project success. Counterfeit materials can lead to failed mold trials and production defects, costing you time and money. The challenge is that fake resins often look identical to the real thing.

First-Step Verification

Always start with the packaging and documentation. Genuine materials have clear, consistent labeling. Check for professional printing quality on bags and boxes. Any blurry logos or typos are immediate red flags for concern.

Quick Comparison Checklist

| Feature | Genuine Makrolon | Potential Counterfeit |

|---|---|---|

| Packaging | Sealed, branded bags; clear printing | Resealed bags, blurry logos, typos |

| Labeling | Consistent batch numbers, correct grade | Missing or inconsistent information |

| Pellet Quality | Uniform size and color | Discoloration, mixed sizes, dust |

A Certificate of Analysis (COA) is your most important document, but it’s not foolproof. Scammers can forge paperwork that looks legitimate. It’s essential to cross-reference the batch number on the COA with the number on the packaging. Any discrepancy means you should stop and investigate further.

The True Cost of Fakes

Using counterfeit resin introduces significant risks to your project. The material might not meet the required thermal or mechanical properties. In our lab tests, we’ve seen fake materials exhibit poor flow during molding, leading to incomplete parts. This wastes machine time and delays your entire schedule. Finding the best suppliers of makrolon involves verifying their quality control processes.

| Risk Category | Consequence of Using Counterfeit Resin |

|---|---|

| Mechanical Failure | Lower impact resistance, parts cracking under stress |

| Processing Issues | Inconsistent melt flow, higher scrap rates |

| Aesthetic Defects | Poor surface finish, color variation, yellowing |

For ultimate certainty, advanced material analysis is necessary. Techniques like Spectroscopy3 can confirm the polymer’s exact chemical fingerprint, leaving no room for doubt. At MTM, we ensure all our pre-stocked materials in China pass these stringent checks. This removes the verification burden from our clients.

Verifying authentic Makrolon resin requires checking the COA, batch numbers, and supplier credibility. Using counterfeit material creates serious performance risks and project delays. Trusting a verified local supplier like MTM ensures you receive genuine material for your mold trials.

Must-Know Import Challenges When Sourcing Makrolon To China

Importing Makrolon for mold trials in China seems straightforward, but it’s filled with hidden hurdles. I’ve seen projects stall due to unexpected customs issues. The primary problem isn’t just shipping time; it’s the unpredictability of the entire process.

The True Cost of Importing

Many teams only calculate the material and shipping fees. However, import tariffs, value-added tax (VAT), and customs brokerage fees can significantly inflate the final cost. These expenses are often overlooked during initial budgeting, causing financial surprises later.

Navigating Customs and Delays

The customs clearance process for Makrolon import to China can be complex. Incorrect documentation or a simple misclassification of the material can lead to Makrolon customs delays lasting weeks. This directly impacts your mold trial schedule and pushes back your entire project timeline.

| Challenge | International Shipping | Local Sourcing (MTM) |

|---|---|---|

| Lead Time | 2-4 weeks (minimum) | 1-3 days |

| Cost | High (shipping + tariffs) | Predictable (local price) |

| Risk | High (delays, loss, damage) | Low (pre-stocked) |

| Paperwork | Complex customs documents | Minimal |

Beyond delays, Makrolon shipping challenges include the risk of material damage or loss. A shipment might get stuck at a port, exposed to improper storage conditions, or simply disappear. When this happens, you have to restart the entire process, doubling your costs and lead time.

Why Material Grade Integrity Matters

Ensuring you receive the exact grade of Makrolon you specified is critical. Polycarbonates like Makrolon are an Amorphous solid4, meaning their molecular structure gives them specific properties like transparency and toughness. The wrong grade can compromise your test results, forcing you to conduct new trials.

The Local Sourcing Solution

A local supplier eliminates these risks entirely. At MTM, we pre-stock common Makrolon grades in China, so they are ready for immediate dispatch. This model removes all customs, shipping, and uncertainty from the equation, making us one of the best suppliers of makrolon for trial purposes.

| Import Risk Factor | Consequence | How MTM Mitigates It |

|---|---|---|

| Customs Hold | Project delays | Eliminated; material is already in China. |

| Shipping Damage | Material unusable | Eliminated; local, secure delivery. |

| Incorrect Grade | Failed trial, re-order | Guaranteed grade verification before dispatch. |

| Hidden Costs | Budget overruns | Transparent, all-inclusive pricing. |

Importing Makrolon to China introduces risks like customs delays, high tariffs, and potential shipping loss. Using a local supplier like MTM bypasses these issues, providing the correct material quickly and predictably, safeguarding your project timeline and budget.

Complete Comparison: Local Chinese Vs Global Makrolon Suppliers

When sourcing Makrolon for mold trials in China, the choice between local and global suppliers is crucial. Your decision impacts project timelines, costs, and material integrity. The best suppliers of makrolon balance these factors effectively, but the path to finding them differs significantly.

Key Decision Factors

Global suppliers offer brand assurance but often come with long lead times. Local suppliers provide speed but may raise concerns about traceability. This comparison is not just about price; it is about total project efficiency and risk management.

Initial Sourcing Comparison

This table outlines the primary differences you’ll encounter when starting your Makrolon sourcing comparison.

| Feature | Global Suppliers | Local Chinese Suppliers |

|---|---|---|

| Lead Time | 4-8 Weeks (or more) | 1-3 Days |

| Logistics | Complex (Customs, Shipping) | Simple (Domestic Delivery) |

| Initial Cost | Higher Material Price | Lower Material Price |

| Flexibility | Low (Fixed MOQs) | High (Smaller Batches) |

Ultimately, understanding these trade-offs helps you select the right partner for your specific mold trial needs in China.

When making a Makrolon sourcing comparison, we must look beyond the initial quote. Responsiveness and material traceability are where the real differences emerge. These factors directly influence your project’s success and can prevent costly delays or quality issues down the line.

Responsiveness and Communication

Global suppliers operate across different time zones, which can delay responses. A simple technical question might take a day to answer. In contrast, a local partner like MTM operates on your China-based mold maker’s schedule, ensuring real-time problem-solving and clear communication.

Material Traceability and Quality Assurance

Traceability is non-negotiable. While global brands provide extensive documentation, verifying it for materials sourced through complex chains can be difficult. We’ve seen projects where understanding a material’s Rheology5 was critical, and only with direct local verification could we confirm the batch data matched the specifications needed for a high-precision mold trial.

| Aspect | Global Sourcing | Local Sourcing (with partner) |

|---|---|---|

| Documentation | Official CoC, CoA | Verified CoC, CoA |

| Batch Consistency | Generally High | Requires Verification |

| Technical Support | Time Zone Delays | Immediate, On-site |

| Risk | Logistics & Delays | Authenticity & Data |

Finding reliable China Makrolon suppliers requires a partner who can validate material integrity on the ground.

Choosing between local and global Makrolon suppliers involves balancing speed, cost, and traceability. The best suppliers of makrolon provide a solution that aligns with your project’s technical requirements and tight timelines, mitigating risks associated with international logistics and ensuring material authenticity.

The Hidden Costs Of Offshore Makrolon Shipping No One Talks About

When sourcing Makrolon, many teams focus only on the material and freight quote. The reality is that the initial shipping price is just the tip of the iceberg. The real financial impact comes from a collection of smaller, often overlooked charges that accumulate during transit.

The Initial Quote vs. Reality

The figure you first see rarely reflects the final bill. These additional costs can easily inflate your initial budget by a significant margin, turning a seemingly good deal into a costly problem.

Common Cost Oversights

Below is a breakdown of what is often quoted versus what you actually pay. This shows the clear difference between the expected and the total landed cost.

| Quoted Costs | Actual Landed Costs |

|---|---|

| Material Price | Material Price |

| Air/Sea Freight | Freight + Insurance |

| – | Customs Duties & Taxes |

| – | Brokerage & Handling Fees |

| – | Administrative Overhead |

This is why understanding the full scope of Makrolon overseas shipping cost is critical before committing.

The complexity of international shipping creates numerous opportunities for unexpected expenses. These polycarbonate import extra fees are not always transparently communicated by freight forwarders. You must proactively account for them in your project’s budget.

Deconstructing Hidden Logistics Costs

A primary issue is customs clearance. A simple documentation error can hold up your shipment for days or even weeks. During this time, your materials are stuck in a warehouse, and your mold trial schedule is completely stalled. This is where costs begin to multiply unexpectedly.

Administrative and Delay-Related Fees

Every day a shipment is delayed, new fees can appear. Port storage fees are charged for occupying space beyond the allotted free time. This hidden Makrolon logistics cost is a direct result of process inefficiencies that are outside of your direct control when managing shipping from abroad. These administrative burdens are often underestimated. The best suppliers of Makrolon are those who help you avoid these logistical nightmares altogether.

| Hidden Cost Type | Description |

|---|---|

| Customs Inspection Fee | Charges for physical inspection of goods by authorities. |

| Port Storage Fee | Daily fees for storing containers at the port after free time expires. |

| Demurrage6 | A penalty charged by the shipping line for late return of containers. |

| Documentation Fee | Charges for correcting or re-issuing shipping documents. |

Working with a local partner like MTM in China eliminates these variables. We handle the material sourcing on the ground, so you never have to deal with the unpredictability of international customs and logistics for your critical mold trials.

The initial freight quote for Makrolon is often misleading. Hidden costs from customs, administrative overhead, and potential delays can significantly increase the total expense, disrupting both your budget and your project timeline.

Why Material Consistency Matters In Every Mold Trial

In every mold trial, the goal is to validate the tool and establish a stable manufacturing process. However, this entire process hinges on one critical factor: material consistency. Using inconsistent batches of plastic resin can completely invalidate your test results, leading to costly errors down the line.

The Problem with Batch-to-Batch Variation

Even materials from the same manufacturer can have slight variations between production lots. These small differences in viscosity, moisture content, or additive levels can significantly impact how the material behaves in the mold. This is a common source of Makrolon mold trial issues.

The Impact on Your Trial Data

When you use an inconsistent material, your carefully recorded processing parameters become unreliable. A process window that works for one batch may not work for the next. This creates a false sense of security and leads to production problems later.

Material inconsistency is more than a minor annoyance; it’s a direct threat to your project’s timeline and budget. An inaccurate mold trial forces you to troubleshoot problems that shouldn’t exist, wasting valuable time and resources on what should have been a straightforward validation.

How Inconsistent Batches Ruin Accuracy

When testing a new mold, engineers adjust parameters like injection speed and pressure. If the material’s Melt Flow Index7 differs from the production batch, these settings become useless. This is why sourcing consistent polycarbonate resins from reliable sources is critical for success.

Case Study: Inconsistent Makrolon Batches

We’ve seen projects where parts from one batch passed quality checks perfectly, while parts from another showed warping and sink marks. The root cause was traced back to batch variation, not the mold. This highlights why finding the best suppliers of makrolon who guarantee consistency is so important.

The table below, based on data from our client studies, illustrates this point clearly.

| Parameter | Batch A (Consistent) | Batch B (Inconsistent) | Impact on Trial |

|---|---|---|---|

| Part Weight | 25.0g ± 0.1g | 24.5g ± 0.4g | Fails dimensional tolerance |

| Injection Pressure | 110 MPa | 130 MPa | Invalidates process window |

| Cycle Time | 22 seconds | 25 seconds | Reduces production efficiency |

| Visual Defects | None | Sink Marks | Requires re-tooling or process changes |

Using inconsistent materials for mold trials creates misleading data and false conclusions. This can lead to incorrect tooling adjustments and significant delays when moving to mass production, undermining the entire purpose of the trial. Sourcing from a trusted supplier is your first line of defense.

The Engineer’s Guide To Choosing The Right Grade Of Makrolon

Choosing the right Makrolon grade is critical for your project’s success. It’s not just about picking a polycarbonate; it’s about matching specific properties to your application’s demands. This PC material selection guide focuses on three key categories to simplify your decision.

Key Makrolon Grade Categories

Understanding the primary function helps narrow the options. Are you designing a lens, an electronics housing, or a protective cover? Each requires a distinct material profile. This initial choice sets the foundation for performance and manufacturability.

Optical, Flame-Retardant, and Impact-Resistant Grades

The main families of Makrolon grades are engineered for specific challenges. Optical grades prioritize clarity and light transmission. Flame-retardant grades ensure safety in electronics, while impact-resistant grades provide durability for demanding physical environments.

| Grade Type | Primary Property | Common Application |

|---|---|---|

| Optical | High Light Transmission | Lenses, Light Guides |

| Flame-Retardant | Self-Extinguishing | Electronic Enclosures |

| Impact-Resistant | High Toughness | Protective Gear, Covers |

When asking, "which Makrolon for my application," you must look beyond the primary datasheet values. Each property enhancement often comes with a trade-off. For instance, adding flame retardants can sometimes reduce the material’s transparency or impact strength, a detail often missed in initial reviews.

Understanding Material Trade-Offs

Many Makrolon grades are compounds, not pure polycarbonate. Additives used to enhance one property can affect others. This is a crucial point many engineers overlook. I always advise my clients to consider the entire performance profile, not just one headline feature.

Impact Modifiers vs. Flow Rate

To boost toughness, manufacturers add impact modifiers. However, these can increase viscosity, making the material harder to inject into complex molds. This can lead to longer cycle times or processing challenges. Knowing this balance is key to successful manufacturing.

Working with experienced partners is essential here. The best suppliers of makrolon don’t just sell resins; they provide application support. At MTM, we help clients understand how Polymer Chain Entanglement8 influences these properties, ensuring their material choice works in production, not just on paper.

| Grade Focus | Potential Trade-Off | Consideration |

|---|---|---|

| Flame Retardancy | Reduced Clarity | Is transparency critical? |

| Impact Resistance | Lower Flow Rate | Can the mold handle higher viscosity? |

| UV Stability | Slight Color Shift | Is perfect color matching required? |

Selecting the correct Makrolon grade requires a balanced approach. You must weigh the primary requirement—be it optical clarity, flame retardancy, or impact resistance—against potential trade-offs in processability and secondary properties. Consulting with material experts can prevent costly trial-and-error cycles.

Proven Strategies To Align Global Specs With Local Makrolon Equivalents

Finding a true Makrolon equivalent in China requires more than just matching a few numbers on a datasheet. Relying solely on spec sheets often leads to performance gaps during mold trials. It’s a common challenge project teams face.

The Data Sheet Dilemma

A global spec sheet lists key properties, but local equivalents may use different testing standards or have minor formulation variances. These subtle differences can significantly impact the final part’s performance and aesthetics during production.

Initial Comparison Points

When starting your search, a basic comparison is a good first step. However, this should not be the final step in your material selection process.

| Property | Global Makrolon Grade | Potential Local Equivalent |

|---|---|---|

| Melt Flow Rate (300°C/1.2kg) | 10 g/10 min | 9.5 g/10 min |

| Color Code | Natural 7035 | Natural Transparent |

| UV Stabilizer | Yes | Yes |

This initial check helps narrow the field, but true equivalency demands deeper analysis.

A material specialist is crucial for successful global-to-local conversion. At MTM, we go beyond simple data comparison. We focus on performance-based equivalency, ensuring the local material behaves exactly as needed in your specific mold and application.

Beyond the Datasheet

We analyze the full context of your project. This includes understanding the part’s end-use, required mechanical stress, and aesthetic criteria. It helps us identify critical performance indicators that aren’t always obvious on a standard technical datasheet. This is where expert polycarbonate grade matching becomes essential.

Performance-Based Equivalency

We help you understand how factors like Isotropy9 can affect your final product. A material that looks identical on paper might perform differently due to processing conditions or subtle additive variations. The best suppliers of Makrolon equivalents provide this level of detailed support.

| Performance Metric | Global Spec Requirement | China-Stocked Equivalent |

|---|---|---|

| Notched Izod Impact (23°C) | 65 kJ/m² | 68 kJ/m² |

| Tensile Modulus | 2400 MPa | 2400 MPa |

| Heat Deflection Temp (1.8 MPa) | 128 °C | 129 °C |

Our analysis ensures the chosen material meets these critical functional demands, not just basic datasheet values.

Aligning global specs with a local Makrolon equivalent in China demands expert analysis beyond the datasheet. A specialist focuses on performance-based matching, considering the application’s unique demands to ensure a truly viable and reliable alternative for your mold trials.

Finding your specified Makrolon grade is unavailable can halt a project. This happens often due to regional supply chain issues or discontinued series. The immediate goal is finding a viable Makrolon substitution that doesn’t compromise your mold trial or final product integrity.

Initial Data Sheet Review

The first step is a side-by-side comparison of data sheets. Look beyond just the grade name. Focus on key performance indicators (KPIs) like Melt Flow Rate (MFR), impact strength, and heat deflection temperature. This helps create a shortlist of potential alternate Makrolon grades.

Verifying Performance Equivalence

A close data match is a good start. However, real-world processing can differ. We always recommend a small trial run to confirm the material behaves as expected in your specific mold, ensuring a seamless transition and avoiding costly surprises down the line.

When you need to match unavailable Makrolon material, a deeper analysis is crucial. Minor differences in data sheets can lead to significant processing or performance issues. We’ve seen cases where a substitute with a slightly different MFR required major adjustments to injection pressure and temperature.

Beyond the Primary Data

Beyond basic specs, consider secondary properties vital to your application. Does your part require UV stability, flame retardancy (like a UL94 rating), or specific color matching? These factors dramatically narrow the list of suitable replacements. The best suppliers of Makrolon understand these nuances.

Comparing Critical Properties

Our analysis with clients often reveals that focusing on one or two key parameters is most effective. For an automotive lens, light transmission and Tensile Modulus10 might be the priority. For an electronics housing, it might be impact strength and flame rating.

| Property | Original Grade (Unavailable) | Potential Alternative |

|---|---|---|

| MFR (300°C/1.2 kg) | 10 g/10 min | 11 g/10 min |

| Notched Izod Impact | 65 kJ/m² | 62 kJ/m² |

| HDT (1.8 MPa) | 128 °C | 126 °C |

| Light Transmission | 89% | 88% |

This structured comparison helps in making an informed decision quickly, ensuring your mold trial stays on schedule without compromising on quality.

When your specified Makrolon is unavailable, a systematic approach is key. By focusing on critical performance data and consulting with experts, you can identify and verify a suitable Makrolon substitution, ensuring your project continues without delay or compromise.

Top 5 Logistics Mistakes When Importing Makrolon To East Asia

Importing Makrolon polycarbonate to East Asia seems straightforward, but small logistical errors can cause major project delays. These issues often stem from simple administrative oversights rather than complex shipping problems. They are costly and entirely preventable with the right knowledge.

Common Administrative Hurdles

Makrolon shipping errors frequently involve incorrect paperwork. A wrong digit in an HS code or a missing document can leave your valuable material stuck at the port for weeks, disrupting your entire mold trial schedule and production timeline.

Frequent Documentation Mistakes

Here is a quick look at common errors and their direct impact on your project.

| Error Type | Consequence |

|---|---|

| Incorrect HS Code | Customs Delays, Fines |

| Incomplete Paperwork | Shipment Hold, Re-submission |

| Wrong Incoterm | Unexpected Costs, Liability |

Navigating international trade involves more than just finding a carrier. Makrolon international trade gaps often appear in the fine print of agreements, specifically with Incoterms. A misunderstanding here can shift significant costs and risks unexpectedly onto you or your supplier.

Breaking Down Critical Details

Many teams assume their freight forwarder handles everything, but accountability is key. For instance, choosing between "Free on Board" (FOB) and "Cost, Insurance, and Freight" (CIF) determines who pays for what and when ownership transfers. This choice impacts your total landed cost.

The Financial Impact of Customs

Incorrectly declared values directly affect the Ad Valorem Duty11 applied by customs, potentially leading to overpayment or penalties. We’ve seen projects incur thousands in extra fees from simple valuation mistakes. The best suppliers of makrolon help you manage these details proactively.

| Incoterm | Buyer’s Responsibility Starts… | Common Mix-Up |

|---|---|---|

| FOB | When goods are on the vessel. | Assuming supplier covers port fees. |

| CIF | At the destination port. | Ignoring local import clearance costs. |

| EXW | At the supplier’s warehouse. | Underestimating export/transport costs. |

Avoiding these Makrolon transportation mistakes requires a partner who understands both the material and the region’s import regulations. At MTM, we handle these logistics daily, ensuring your material is ready in China without these cross-border headaches.

Simple errors in HS codes, documentation, and Incoterms cause significant delays and inflate costs when importing Makrolon. Proactive management and expert oversight are essential to prevent these common logistics failures and keep your project on track.

Makrolon Emergency Sourcing: What To Do When Timelines Collapse

When you have an urgent Makrolon need, waiting for international shipments is not an option. Project timelines can collapse under the weight of shipping delays and customs issues. The key is to act fast and look for local solutions that can save your project.

Evaluating Local Sourcing Options

Your first step in a Makrolon emergency sourcing situation is identifying local suppliers. Not all suppliers are equal. You need a partner who has the specific grade you require in stock and can deliver it immediately. This is where pre-stocked inventory becomes a critical advantage.

The Role of Equivalent Materials

If the exact grade isn’t available, a validated equivalent material is your next best option. A reliable local partner can help you compare datasheets to ensure the substitute meets your mold trial requirements without compromising the final product’s integrity.

| Sourcing Method | Typical Lead Time | Risk Factor |

|---|---|---|

| International Shipment | 4-8 Weeks | High |

| Standard Local Order | 1-2 Weeks | Medium |

| MTM Pre-Stocked Material | 1-3 Days | Low |

Choosing a Reliable Equivalent

When switching materials, technical validation is crucial. You cannot just pick another polycarbonate. You must compare critical properties. This ensures the material behaves as expected during the mold trial and accurately reflects the performance of the intended production-grade resin. An urgent situation demands precision.

Key Performance Indicators

Based on our test results, we focus on three core areas: Melt Flow Index (MFI) for processability, Notched Izod Impact for toughness, and Heat Deflection Temperature (HDT) for thermal stability. A mismatch in these can lead to failed trials and inaccurate data.

Beyond the Datasheet

Sometimes, a datasheet doesn’t tell the whole story. Properties like Glass Transition Temperature12 can influence how the material behaves under specific processing conditions. At MTM, we help clients navigate these nuances, ensuring the Makrolon express supply we provide, or its equivalent, is the right fit. As one of the best suppliers of makrolon for trials in China, we prioritize this validation.

| Property | Makrolon 2805 | Potential Equivalent A |

|---|---|---|

| MFI (300°C/1.2 kg) | 10 g/10min | 9.5 g/10min |

| Notched Izod Impact (23°C) | 65 kJ/m² | 62 kJ/m² |

| HDT (1.8 MPa) | 129°C | 127°C |

When facing a Makrolon emergency sourcing crisis, your best options are pre-stocked local materials or carefully vetted equivalents. This strategy mitigates risks from shipping delays and ensures your mold trial schedule remains intact, keeping your entire project timeline on track.

How To Ensure Repeatability With Every Batch Of Makrolon Resin

Achieving consistent results in mold testing starts with a disciplined approach. Makrolon repeatability depends heavily on controlling every variable, from material handling to machine settings. Minor deviations can lead to significant differences in final part quality, making your data unreliable and delaying project timelines.

Standardizing Your Process

The first step is establishing a strict protocol. Document every setting and procedure. This ensures anyone on your team can replicate the exact conditions for each test. This is fundamental for effective Makrolon mold quality control.

| Parameter | Standard Setting | Tolerance |

|---|---|---|

| Drying Temperature | 120°C (248°F) | ± 2°C |

| Drying Time | 4 Hours Minimum | +30 minutes |

| Melt Temperature | 280-320°C (536-608°F) | ± 5°C |

| Mold Temperature | 80-120°C (176-248°F) | ± 2°C |

Material Handling Discipline

How you handle the resin before it even enters the machine is critical. Proper drying is non-negotiable for polycarbonate to prevent hydrolysis. Consistent material handling ensures Makrolon batch consistency from the start.

True Makrolon batch consistency goes beyond just the material itself. It extends to how you manage the entire molding environment. Uncontrolled variables can undermine even the highest quality resin, leading to frustrating and costly re-tests. This is why strict process control is essential.

Environmental and Equipment Factors

Your facility’s ambient temperature and humidity can influence resin performance. A machine’s calibration can also drift over time. Regular checks and adjustments are necessary to maintain a stable processing window. This meticulous attention to detail is what separates a good test from a great one.

The Impact of Pre-Processing

A material’s behavior is influenced by its history. Factors like storage conditions and drying time affect its Viscoelasticity13. This property describes how a material deforms under stress. Inconsistent pre-processing alters this behavior, leading to varied outcomes even with identical machine settings.

| Condition | Impact on Consistency | Recommended Action |

|---|---|---|

| Inconsistent Drying | High variability, splay | Standardize drying time/temp |

| Fluctuating Humidity | Minor changes in flow | Control plant environment |

| Uncalibrated Machine | Pressure/temp deviation | Regular maintenance schedule |

At MTM, we support clients by providing material from reliable sources. When you work with the best suppliers of Makrolon, you get a consistent starting point. This allows you to focus on refining your process for perfect Makrolon repeatability.

Ensuring repeatability with Makrolon resin requires a holistic approach. It involves standardizing machine settings, implementing strict material handling protocols, and controlling environmental factors. This discipline guarantees reliable and consistent mold test results every single time.

Makrolon Label Decoding: What Procurement Should Look For

Understanding the data on a Makrolon label is critical for procurement. It’s more than just a sticker; it’s a quality guarantee. Each detail confirms you have the right material for your mold trial, directly impacting performance and traceability from the start.

Key Label Information

The label provides essential data for verification. Neglecting this information can lead to costly errors in production. The best suppliers of makrolon ensure every bag is clearly and accurately labeled for complete transparency and confidence in your supply chain.

Essential Data Points

| Data Point | Importance |

|---|---|

| Grade | Specifies material properties and performance. |

| Lot Number | Ensures full traceability for quality control. |

| Expiry Date | Guarantees material is within its optimal shelf life. |

| Net Weight | Confirms the quantity received matches your order. |

A proper Makrolon labeling guide helps you avoid common pitfalls. The grade isn’t just a name; it’s a formula. For instance, a number like ‘2405’ indicates specific properties like melt flow rate and additives. Misinterpreting this leads to incorrect processing parameters.

Understanding Resin Coding Meaning

Each part of the code has a purpose. The lot number is your most critical tool for Makrolon lot traceability. If a batch shows defects, this number allows you to track its origin, production date, and sibling batches, isolating the problem quickly.

A Closer Look at Traceability

The expiry date is equally important. Polycarbonate is a hygroscopic14 material, meaning it absorbs moisture. Using expired resin, even if it looks fine, can introduce processing issues like splay or brittleness. At MTM, we ensure all our stock is well within its recommended shelf life.

| Code Element | Example | What It Tells You |

|---|---|---|

| Grade ID | Makrolon 2405 | Viscosity, UV stabilization, color. |

| Lot Number | 8564321A | Unique batch identifier for tracking. |

| Production Date | 2023/10/15 | When the material was manufactured. |

| Expiry Date | 2025/10/14 | Last day for guaranteed performance. |

Decoding Makrolon labels is a fundamental skill for procurement. It ensures material authenticity, supports quality control through lot traceability, and prevents costly production issues by verifying grades and expiry dates, safeguarding your project’s integrity and timeline.

When To Specify Flame-Retardant Makrolon Grades And Why It Matters

Choosing a flame-retardant (FR) Makrolon grade is not just about ticking a box; it’s a critical engineering decision. It ensures product safety, regulatory compliance, and brand reputation. For many applications, especially in electronics and public transportation, standard grades are simply not an option.

The Initial Assessment

The first question is always about the end-use environment. Will the component be near a heat source or ignition point? If so, an FR grade is essential. Neglecting this can lead to catastrophic failures and liability issues that far outweigh the initial material cost savings.

Key Deciding Factors

| Factor | Standard Makrolon | FR Makrolon |

|---|---|---|

| Safety Compliance | Fails most fire tests | Passes specific UL94 ratings |

| Application Risk | High in electronics/auto | Mitigated for safety |

| Material Cost | Lower | Higher due to additives |

Navigating the Makrolon Fire Rating Guide

Understanding the UL94 standard is crucial. It is the primary guide for a material’s fire rating. Most FR Makrolon grades are specified to meet UL94 V-0, V-1, or V-2 ratings. Each rating corresponds to a specific performance level in controlled flame tests.

Matching UL94 Ratings to Applications

A V-0 rating is one of the highest, required for components in enclosures for electronic devices where fire containment is paramount. During the test, burning must stop within 10 seconds. In contrast, a V-2 rating allows for flaming drips, making it unsuitable for parts positioned above sensitive electronics.

When our clients are deciding, we often use a simple guide to help them.

| UL94 Rating | Self-Extinguishing Time | Dripping Behavior | Common Application |

|---|---|---|---|

| V-0 | < 10 seconds | No flaming drips | Power supply housings |

| V-1 | < 30 seconds | No flaming drips | Connectors, switches |

| V-2 | < 30 seconds | Flaming drips allowed | Some appliance parts |

The process of Pyrolysis15 is what these tests evaluate. They measure how quickly a material breaks down under heat and whether it sustains a flame. Getting this right is non-negotiable. That’s why working with the best suppliers of makrolon is so important, as they ensure traceability and certified materials. At MTM, we stock these specific FR Makrolon grades in China to avoid project delays.

Specifying the correct FR Makrolon grade is a fundamental step in responsible product design. It’s about ensuring safety and meeting non-negotiable industry standards. The UL94 rating system provides a clear framework for making the right material choice for your application’s risk profile.

Makrolon For Optical Applications: How To Source The Right Grade

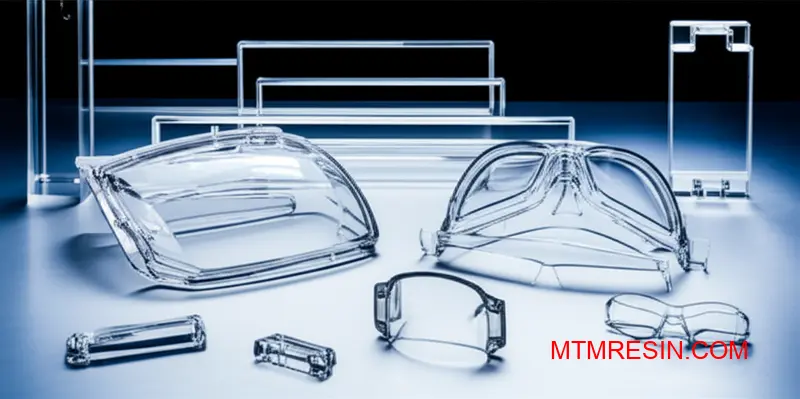

When sourcing optical grade Makrolon, clarity is everything. We focus on two key metrics for our clients: light transmission and resistance to yellowing. High light transmission, often above 89%, ensures maximum brightness for applications like automotive headlamps and light guides. This is non-negotiable for performance.

Long-Term Clarity

Equally important is yellowing resistance. Materials exposed to UV light can degrade, losing clarity over time. Optical grades include UV stabilizers to prevent this. Selecting the right grade from the start prevents costly failures later on, which is a common issue we help clients avoid during mold trials.

Typical Use Cases

Here are some common applications where specific Makrolon grades excel.

| Application | Key Requirement | Recommended Grade Type |

|---|---|---|

| Automotive Lenses | High transmission, UV resistance | Makrolon AL (Automotive Lighting) |

| Safety Glasses | Impact strength, clarity | Makrolon 2405 / 2605 |

| LED Light Guides | High purity, minimal haze | Makrolon LED series |

| Medical Devices | Sterilization resistance, clarity | Makrolon Rx series |

Beyond the Basics of Optical Grade Makrolon

Choosing a clear polycarbonate material isn’t just about picking one with high light transmission. The datasheet tells a deeper story. For example, haze is a critical factor that is often overlooked. A material can have high transmission but still appear cloudy if the haze value is too high.

The Role of Processing

Processing conditions during injection molding directly impact optical performance. Incorrect melt temperatures or cooling rates can introduce stress, which affects clarity. This is why using the exact specified grade during mold trials at MTM is crucial. It validates both the material and the process together.

Material Specification Table

Understanding the subtle differences between grades is key. After working with our clients, we have found these distinctions to be the most critical when selecting Makrolon for lenses or other demanding optical parts. Partnering with the best suppliers of makrolon ensures access to certified grades with guaranteed specifications.

| Property | Standard Grade (e.g., Makrolon 2805) | Optical Grade (e.g., Makrolon AL2647) |

|---|---|---|

| Light Transmission (3mm) | ~88% | >89.5% |

| Haze | <1.0% | <0.5% |

| UV Stabilization | Standard | Enhanced for outdoor use |

| Refractive Index16 | ~1.586 | ~1.586 |

The refractive index remains consistent, but other properties are enhanced for optical applications.

Choosing the right optical grade Makrolon requires analyzing specifications like light transmission, haze, and UV resistance. The final application dictates which properties are most critical, and proper material selection is essential for ensuring long-term performance and aesthetic clarity in the final product.

Polycarbonate Alternatives To Makrolon In Downtime Scenarios

When Makrolon faces supply chain disruptions, your project doesn’t have to stop. Having a backup plan with a reliable Makrolon alternative resin is crucial for keeping mold trials on schedule. The key is identifying a substitute PC material that matches the required performance characteristics.

Top-Tier Alternatives

Several globally recognized brands offer comparable polycarbonate grades. These options ensure you maintain quality and consistency without significant delays.

Key Replacement Options

| Brand Name | Manufacturer | Key Benefit |

|---|---|---|

| Lexan | Sabic | Wide grade availability, strong technical support. |

| Iupilon | Mitsubishi | Excellent optical clarity and dimensional stability. |

| Calibre | Trinseo | Known for consistent processing and quality. |

These are the primary Makrolon replacement options we recommend to clients facing sourcing issues.

When evaluating a substitute for Makrolon, a datasheet comparison is only the starting point. Finding the best suppliers of makrolon can be tough, but finding a suitable replacement requires careful analysis. At MTM, we help clients navigate these Makrolon replacement options.

Comparing Major Brands

Sabic’s Lexan is often the first choice. Many of its grades are direct drop-in replacements for popular Makrolon series. Mitsubishi’s Iupilon is another excellent choice, particularly for applications demanding high optical quality. We focus on matching critical properties for mold trials.

Matching Material Properties

We compare more than just basic specs. After working with our clients, we found that matching the Melt Volume-Flow Rate (MVR)17 is essential for a successful mold trial. This ensures the substitute PC material behaves similarly in the mold, minimizing process adjustments and saving valuable time.

Local Chinese brands can also be viable. However, they require rigorous testing to validate performance consistency. We always advise a thorough evaluation before committing to a local equivalent for a critical project. This ensures the material meets your exact engineering requirements.

During supply chain disruptions, having tested Makrolon alternatives is key to avoiding delays. Major brands like Sabic Lexan and Mitsubishi Iupilon offer reliable, high-quality substitute PC materials that can keep your mold trial projects on track.

Why More R&D Teams Are Choosing MTM For Makrolon Trial Materials

R&D teams often face tight deadlines. Sourcing specific materials like Makrolon for mold trials in China can cause significant delays. Waiting for shipments from overseas is a common bottleneck that disrupts the entire development schedule. This is where having a local partner changes the game.

The Advantage of Local Supply

Choosing a local Makrolon supplier in China eliminates cross-border shipping complexities. At MTM, we stock MTM Makrolon resin locally, so your material is ready for immediate dispatch to your mold maker’s facility. This dramatically shortens your lead time.

Traditional vs. MTM Sourcing

| Feature | Overseas Shipping | MTM Local Supply |

|---|---|---|

| Lead Time | 3-5 Weeks | 1-3 Days |

| Logistics | Complex Customs | Simple Local Delivery |

| Project Risk | High (Delays, Damage) | Low |

| Cost | High Freight & Duties | No International Fees |

When teams search for the best suppliers of makrolon, they’re often looking for more than just a vendor. They need a reliable Makrolon trial material partner who understands the urgency of mold trials. The traditional process of importing small trial quantities is inefficient and costly.

Overcoming Logistical Hurdles

Shipping materials internationally involves customs paperwork, duties, and potential delays that are out of your control. A simple documentation error can hold up a shipment for weeks, stalling your project. We handle all of that by providing the material directly from our warehouse in China.

Ensuring Material Integrity

Material consistency is critical for valid trial results. We ensure the Makrolon you receive matches your exact specifications. This consistency affects key properties, including the polymer’s Crystallinity18, which influences the final part’s strength and clarity. A reliable supply chain protects material integrity.

| Risk of Overseas Shipping | MTM’s Solution |

|---|---|

| Customs Delays | Pre-stocked material in China |

| Shipping Damage | Secure, local logistics |

| Incorrect Grade | Verified material matching specs |

| High Costs | Eliminates freight & import taxes |

Choosing MTM as your Makrolon trial material partner means you get the right material quickly and reliably. This local approach eliminates logistical headaches, reduces costs, and accelerates your product development timeline, making us a strategic choice for teams manufacturing in China.

Accelerate Your Makrolon Success With MTM’s Local Advantage

Ready to conquer your Makrolon sourcing challenges? Send an inquiry to MTM now—your pre-stocked Makrolon hub in China. Get brand-assured, traceable, and rapid-delivery materials for mold trials, avoid import headaches, and ensure true production consistency. Let’s make your next project faster, safer, and smarter together!

-

Understanding this optical property is crucial for applications where clarity and minimal distortion are critical. ↩

-

Understanding HS Codes helps prevent costly customs delays and ensures smooth international shipping for your materials. ↩

-

Understand how this technique helps identify a material’s unique chemical signature, ensuring authenticity. ↩

-

Understanding this structure helps predict material behavior like transparency and impact resistance in your final product. ↩

-

Understanding this helps predict material flow, crucial for optimizing injection molding process parameters. ↩

-

Understanding this term helps you prevent unexpected and costly port-related penalties on your shipments. ↩

-

Learn how this key metric predicts a polymer’s processability and ensures consistent manufacturing results. ↩

-

Learn how this microscopic structure dictates material toughness and processing behavior. ↩

-

Learn how this property impacts material uniformity and performance predictability in your final parts. ↩

-

Understand how this value predicts a material’s stiffness and its real-world performance under load. ↩

-

Understanding this customs duty helps you accurately budget for import costs and avoid financial surprises. ↩

-

Understand this property to predict material behavior under thermal stress and ensure process stability. ↩

-

Understanding this property helps predict how Makrolon responds to molding pressures and temperatures. ↩

-

Understanding this property is crucial for proper material handling and preventing processing defects. ↩

-

Understanding this process helps predict material behavior in fire scenarios and select the right FR additives. ↩

-

Learn how this critical value influences light bending and optical component design. ↩

-

Understanding this metric is crucial for matching processing parameters between different polycarbonate grades. ↩

-

Understanding this property helps in predicting the material’s mechanical strength and optical clarity. ↩