Injection molding with Makrolon polycarbonate often seems straightforward until you encounter grade confusion, processing defects, or material sourcing delays. Engineers frequently struggle with selecting the right grade from Covestro’s extensive portfolio, only to face silver streaks, bubbles, or authentication issues during critical trial phases.

Makrolon injection molding requires careful grade selection, precise processing parameters, and reliable material sourcing to achieve consistent results. Success depends on understanding the nomenclature system, optimizing temperature profiles, and ensuring material authenticity throughout the trial process.

This comprehensive guide walks you through the complete Makrolon injection molding process, from decoding grade nomenclatures to troubleshooting common defects. I’ll share practical insights from working with engineering teams who’ve successfully navigated these challenges during their molding trials in China.

The Makrolon portfolio can seem complex, but its naming system is quite logical once you grasp the basics. Understanding it is key to selecting the correct polycarbonate grade for your mold trials, preventing costly errors. At MTM, we often help clients decode these names.

The Core Numbering System

The primary identifier is a four-digit number. The first digit often indicates a general family or application type. For instance, the 2000 series is a standard, general-purpose family, while other series may signify specialized properties like flame retardancy or UV stability.

Viscosity Indicators Explained

The last two digits in many common grades correlate directly with viscosity, measured by the Melt Volume-Flow Rate (MVR). A lower number means higher viscosity (slower flow), and a higher number indicates lower viscosity (faster flow). This is critical for processing.

| Grade | MVR (300°C/1.2 kg) | Common Application |

|---|---|---|

| Makrolon 2405 | 19 cm³/10 min | Easy-flowing, thin walls |

| Makrolon 2805 | 10 cm³/10 min | Medium-viscosity, general |

| Makrolon 3105 | 6.0 cm³/10 min | High-viscosity, extrusion |

Choosing between high and low viscosity grades like Makrolon 2407 versus 2805 is a common challenge for engineering teams. The decision directly impacts both the molding process and the final part’s performance. It’s not just about whether the material will fill the mold.

Impact of Viscosity on Molding

A lower viscosity (higher MVR) grade flows more easily, making it suitable for parts with complex geometries or thin walls. However, this can sometimes lead to reduced mechanical strength. High viscosity grades provide better impact resistance and durability but require higher injection pressures and temperatures.

Selecting the Right Grade

The polycarbonate melt flow rate must match your tool design and part requirements. In my experience, using a grade with the wrong MVR can cause issues like flash if viscosity is too low, or short shots if it’s too high. This is why having access to multiple grades for trials is so important. A Thermoplastic1 material’s behavior is predictable if you know its core properties.

| Viscosity Level | Typical MVR Range | Processing Considerations | Part Performance |

|---|---|---|---|

| Low | >15 cm³/10 min | Lower pressure, faster cycles | Good for intricate details |

| Medium | 8-15 cm³/10 min | Balanced processing window | Versatile, general use |

| High | <8 cm³/10 min | Higher pressure & temperature | Superior toughness, strength |

Understanding Makrolon’s nomenclature is crucial for efficient material selection. Paying attention to the series and viscosity indicators helps ensure your chosen grade aligns perfectly with your application’s processing demands and final performance requirements, saving time during critical mold trials.

General Purpose vs. Specialty Grades: Matching Resin to Application

Choosing the right resin is more than just picking a material type. It’s about matching specific properties to your application. A general purpose polycarbonate like Makrolon 2805 is a workhorse, great for many indoor applications. But what if your part will be outdoors or has complex geometry?

General Purpose PC

General purpose grades offer a baseline of excellent impact strength and clarity. They are cost-effective and widely available, making them ideal for initial mold trials where form and fit are the primary concerns. They provide a reliable standard for most internal components.

The Need for Specialty Grades

Specialty grades are engineered with additives to enhance performance. For instance, UV stabilized polycarbonate is essential for outdoor products to prevent yellowing and degradation. Mold release grades help parts eject smoothly from intricate molds, reducing cycle times and cosmetic defects.

| Grade Type | Key Feature | Common Use Case |

|---|---|---|

| General Purpose | Standard Performance | Indoor housings, light pipes |

| UV Stabilized | Sunlight Resistance | Outdoor lighting, enclosures |

| Mold Release | Easier Ejection | Complex, thin-walled parts |

The decision between a standard and specialty resin often hinges on two key factors: environmental exposure and manufacturing complexity. Failing to consider these can lead to part failure or production delays. It is a critical step in any PC resin selection guide.

Why UV Stabilization Matters

A standard PC part exposed to sunlight will degrade. The material becomes brittle and discolored due to a process called Photo-oxidation2. UV stabilized polycarbonate contains additives that absorb UV radiation, protecting the polymer structure and ensuring long-term durability for outdoor applications.

The Role of Mold Release Agents

For parts with deep ribs or textured surfaces, a mold release grade is invaluable. These internal lubricants reduce friction between the plastic and the steel mold. This allows for faster, cleaner part ejection, minimizing stress marks and improving overall production efficiency, a key benefit we see in client trials.

At MTM, we stock both general purpose and specialty Makrolon grades. This ensures your mold trials in China use the precise material specified for the end product, preventing validation issues down the line.

| Scenario | Recommended Grade | Reason |

|---|---|---|

| Automotive headlamp lens | UV Stabilized PC | Must withstand constant sun exposure |

| Medical device with small snaps | Mold Release PC | Ensures clean release of fine features |

| Internal electronic housing | General Purpose Makrolon | No special environmental or molding needs |

Selecting the correct resin grade from the start is crucial. General purpose resins like Makrolon 2805 are excellent for many uses, but specialty grades with UV stabilization or mold release agents are essential for specific performance and manufacturing needs, ensuring product longevity and efficiency.

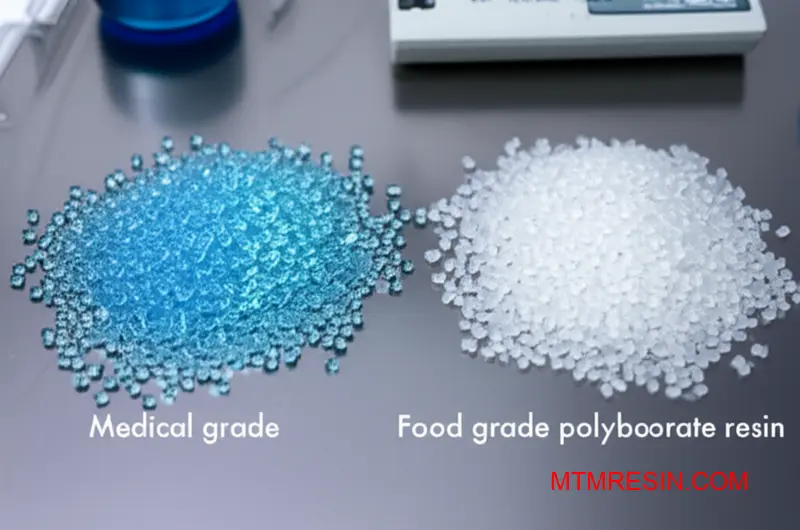

Medical and Food Contact Compliance: Selecting Makrolon Rx and Food Grades

Choosing the right Makrolon grade is critical for regulated products. This decision extends beyond simple mechanical properties; it directly impacts patient safety and consumer protection. The choice between medical and food-grade materials is not interchangeable and demands careful consideration.

Key Designation Differences

The primary distinction lies in their intended use and the regulations they meet. Makrolon Rx grades are for medical devices, while food grades are for applications like kitchenware. Confusing them can cause major project setbacks and compliance failures during audits.

| Grade Type | Primary Application | Key Regulatory Focus |

|---|---|---|

| Makrolon Rx | Medical Devices | Biocompatibility (ISO 10993) |

| Makrolon Food | Food Contact Items | Migration Testing (FDA, EU 10/2011) |

Impact on Project Timelines

Selecting the wrong material often leads to failed validation tests and expensive redesigns. At MTM, we stock both types of Makrolon resin in China, ensuring your mold trials proceed with the correct, compliant material from day one.

Navigating Medical Device Regulations

For medical devices, the governing standard is ISO 10993. This protocol evaluates the biocompatibility3 of materials, ensuring they do not cause adverse biological reactions when in contact with the body. It is a fundamental requirement for patient safety.

The Makrolon Rx series, a leading biocompatible polycarbonate, is specifically designed and tested against these rigorous standards. Using a pre-certified Makrolon medical grade material provides manufacturers with a significant head start, streamlining the device validation process and reducing risks.

Food Contact Compliance Essentials

For food contact applications, regulations such as FDA CFR 21 in the United States and EU 10/2011 in Europe are the primary concern. These standards focus on limiting the migration of substances from the plastic into food, protecting consumers.

| Regulation | Primary Focus | Testing Scope | Example Material Use |

|---|---|---|---|

| ISO 10993 | Biological reaction | Cytotoxicity, sensitization | Surgical tools, drug delivery |

| FDA / EU | Chemical migration | Extractables, leachables | Food containers, utensils |

Selecting an FDA compliant PC resin is essential for any product intended to touch food. While some materials might meet requirements for both sectors, using a dedicated food-grade Makrolon is the safest and most efficient approach for these applications.

Choosing between Makrolon Rx and food grades depends entirely on the end-use regulatory environment. Medical applications demand biocompatibility under ISO 10993, while food contact requires migration testing for FDA compliance. Making the correct choice upfront is critical for project success.

Flame Retardant Solutions: Deep Dive into Makrolon FR Series

When selecting materials for electronics or automotive parts, safety is non-negotiable. Flame retardant (FR) properties are critical. The Makrolon FR series from Covestro offers reliable solutions, specifically designed to meet stringent industry standards for flame retardant PC. These materials ensure safety without compromising performance.

Key Applications for Makrolon FR Grades

Understanding which grade suits your project is the first step. Different applications demand specific flame retardancy levels and physical properties. We often assist clients in navigating these choices for their mold trials in China, ensuring they get the right material from the start.

| Grade Example | Primary Feature | Common Application |

|---|---|---|

| Makrolon FR7087 | UL94 V-0 @ 1.5 mm | Electronic Housings |

| Makrolon FR7067 | UL94 5VA @ 3.0 mm | Power Supply Units |

| Makrolon FR6005 | High Flow, V-0 | Thin-Walled Parts |

This series provides a robust foundation for safe and durable product design.

Understanding Flammability Ratings

For electronic housing materials, the UL94 standard is the universal benchmark. A UL94 V-0 rating means the material self-extinguishes within 10 seconds after two flame applications. This is essential for preventing fires in consumer electronics and other devices where safety is paramount.

The Trade-Off: FR Additives vs. Material Flow

Achieving a UL94 V-0 rating in polycarbonate requires specific additives. However, these additives often increase the material’s viscosity. This makes the molten plastic flow less easily during injection molding. This trade-off is a major consideration for parts with complex geometries or thin walls.

An increased level of FR additives can impact key processing parameters. The choice of Makrolon grade must balance the required safety rating with the manufacturability of the component. Some flame retardants use an Intumescent4 mechanism to create a protective char layer.

Impact on Processing

Here is a simplified view of the relationship between FR level and Melt Flow Index (MFI), based on our testing data. A lower MFI indicates poorer flow.

| FR Additive Level | Typical UL94 Rating | Relative MFI |

|---|---|---|

| Low | V-2 | High |

| Medium | V-0 @ 3.0 mm | Medium |

| High | V-0 @ 1.5 mm | Low |

At MTM, we stock various Makrolon FR grades to help clients quickly test which material provides the best balance for their specific mold and application right here in China.

Makrolon FR series provides essential UL94 V-0 rated materials for safety-critical applications. Engineers must carefully balance these flame retardant properties against processing requirements, particularly material flow, to ensure successful manufacturing of complex electronic and automotive components.

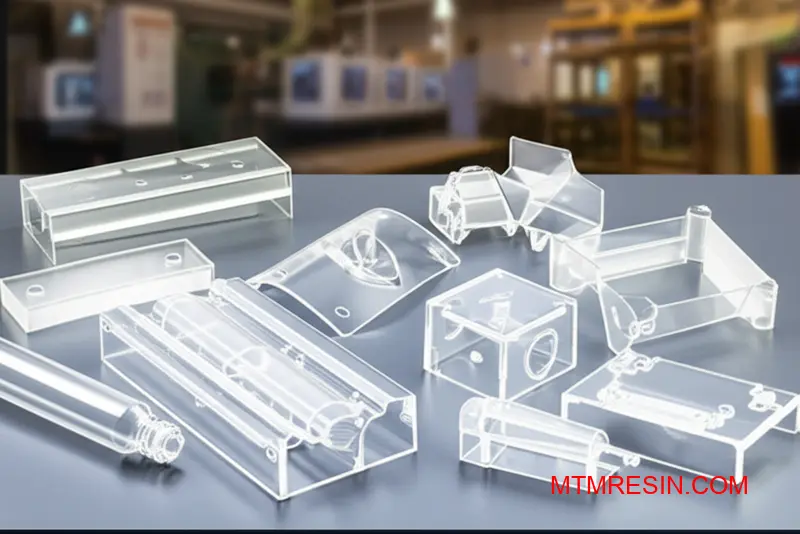

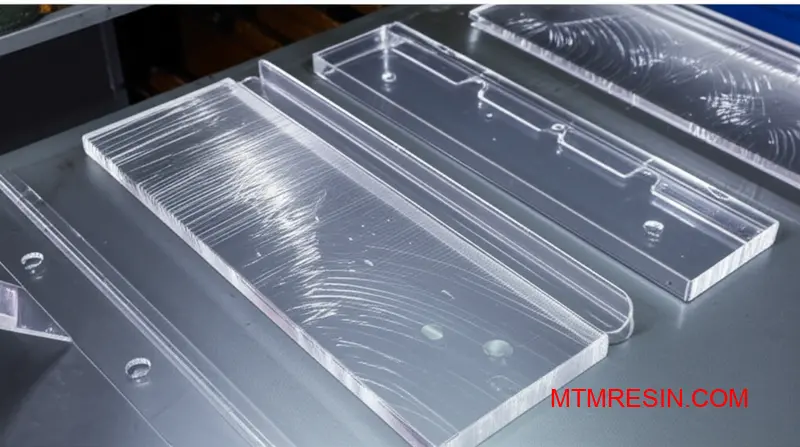

Optical Quality and Light Transmission: Considerations for Transparent Parts

The Critical Role of Clarity

In applications like automotive lighting and consumer electronics, optical quality is non-negotiable. The material’s ability to transmit light without distortion directly impacts performance and safety. Selecting the right resin is the first and most crucial step in the design process for any transparent part.

Key Performance Metrics

We focus on two main factors: light transmission percentage and haze level. A higher transmission rate ensures maximum brightness, while low haze guarantees clarity. Materials like optical-grade Makrolon are engineered specifically to excel in these areas, making them ideal for demanding applications.

Material Comparison

Here is a quick overview of common transparent materials we often discuss with clients for mold trials.

| Material | Light Transmission (%) | Haze (%) |

|---|---|---|

| PC (General Purpose) | 85-89 | >1.0 |

| PC (Optical Grade) | 89-92 | <1.0 |

| PMMA | 92-93 | <1.0 |

| COC/COP | 91-92 | <0.5 |

As you can see, the grade of the material, such as specific optical-grade polycarbonate, makes a significant difference.

Advanced Material Considerations for Lenses

When working with lighting and automotive lens manufacturers, the conversation goes beyond basic clarity. We must address long-term performance under harsh conditions. For these clients, material selection is about balancing initial optical quality with durability over the product’s lifespan.

Meeting Automotive Standards

Automotive lenses require materials that resist yellowing from UV exposure and can withstand temperature fluctuations. High-transmission polycarbonate, especially grades like Makrolon LED2245, is a popular choice. It offers excellent thermal stability and UV protection, ensuring the lens remains clear and functional for years.

The Challenge of LED Lighting

Modern LED lighting systems are highly efficient but can generate localized heat. The material must not only transmit light effectively but also manage thermal stress without degrading. We often help clients at MTM source specific resins designed to minimize Birefringence5 and other optical defects during molding. Selecting the correct automotive lens resin from the start prevents costly mold adjustments and trial delays, ensuring projects stay on schedule. This is where having materials pre-stocked in China becomes a major advantage for our clients’ tight development timelines.

Choosing the right transparent material involves balancing optical performance, durability, and processability. Optical-grade resins like specific Makrolon grades are engineered for demanding applications, ensuring high light transmission and low haze, which are critical for automotive and LED lighting product success.

Optimizing Injection Molding Parameters: Temperature and Pressure Control

Getting temperature and pressure right is fundamental in injection molding. For a material like Makrolon polycarbonate, precise control prevents defects. If barrel temperatures are too low, the material won’t flow properly. If too high, it can degrade, causing brittleness or discoloration.

Proper settings ensure part quality. The goal is a stable process that produces consistent, high-quality components. We often advise clients to establish a baseline and adjust incrementally based on the specific mold and part geometry.

Barrel and Mold Temperature

The barrel temperature profile is critical. It should gradually increase from the feed zone to the nozzle to ensure uniform melting. A poorly set profile can lead to unmelted particles or material degradation, which directly impacts the final product’s strength and appearance.

Mold temperature is just as important. It influences the cooling rate, which affects surface finish, shrinkage, and internal stress. For PC materials like Makrolon, a higher mold temperature is often required to achieve a good surface and minimize stress.

| Parameter | Recommended Range (°C) | Notes |

|---|---|---|

| Barrel Rear Zone | 260 – 280 | Ensures proper material feeding |

| Barrel Middle Zone | 280 – 300 | Primary melting zone |

| Barrel Front Zone | 290 – 310 | Homogenizes melt temperature |

| Nozzle Temperature | 285 – 305 | Slightly lower to prevent drooling |

| Mold Temperature | 80 – 120 | Higher temps improve surface finish |

The Link Between Speed and Stress

Injection speed directly relates to the internal stress within a molded part. A faster injection fills the mold quickly, but it can create high shear rates in the molten polymer. This process introduces significant stress, which can lead to warping or cracking later.

Finding the balance is key. Based on our tests with clients, starting with a moderate speed and observing the results is a practical approach. You must consider how the material behaves under different flow conditions, a concept central to material Rheology6. This helps predict how pressure is transmitted through the melt.

Injection Pressure Settings

Injection pressure must be sufficient to fill the cavity completely before the material freezes. However, excessive pressure can cause flash or over-packing, leading to dimensional issues. Holding pressure is then applied to compensate for material shrinkage as it cools.

This two-stage pressure control is crucial for dimensional accuracy. Getting it right requires experience, especially when using specific grades like Makrolon. At MTM, we supply the exact materials needed for these trials, eliminating variables and helping teams focus solely on process optimization.

| Injection Parameter | Effect of Being Too High | Effect of Being Too Low |

|---|---|---|

| Injection Speed | High internal stress, flash | Short shots, flow marks |

| Injection Pressure | Flash, over-packing, part stress | Short shots, sink marks |

| Holding Pressure | Hard to eject, high stress | Sink marks, voids, warping |

Mastering barrel and mold temperatures, along with injection pressure and speed, is essential for high-quality molding. Using the correct parameters for materials like Makrolon prevents common defects, reduces internal stress, and ensures consistent part integrity for any project.

Mitigating Common Defects: Solving Silver Streaks, Bubbles, and Splay

Visual defects like silver streaks, bubbles, and splay can halt a project. When working with materials like Makrolon, these issues often point to a few core processing problems. Understanding their root causes is the first step toward a solution.

Identifying the Defect’s Origin

These defects might look similar, but they stem from different issues. Silver streaks and splay are often caused by moisture, while bubbles can indicate trapped gas or material degradation. Correctly identifying the problem saves valuable time on the molding floor.

Common Causes at a Glance

A systematic approach helps isolate the variable causing the defect. Before making major adjustments, it’s crucial to confirm the basics, such as material handling and machine settings.

| Defect | Primary Suspect | Secondary Suspect |

|---|---|---|

| Silver Streaks | Moisture in Material | Trapped Air |

| Bubbles | Thermal Degradation | Poor Venting |

| Splay Marks | Insufficient Drying | Excessive Shear Heat |

A Quick Check

Running a quick "air shot" by purging material into the open can help. If the purged material shows bubbles or streaks, the issue is likely with the material or barrel conditions, not the mold itself.

Troubleshooting Deep Dive

For engineers and technicians, a clear diagnostic path is essential. Let’s break down the solutions for polycarbonate molding defects, linking them to moisture, heat, or venting problems specifically in materials like Makrolon.

Moisture-Induced Defects

Polycarbonate is Hygroscopic7, meaning it readily absorbs moisture from the air. If not dried properly, this moisture turns to steam in the barrel, causing silver streaks and splay marks on the part surface. This is the most common cause of such visual defects.

Heat-Related Issues

Excessive heat or prolonged residence time can degrade Makrolon, releasing gases that form bubbles within the part. This differs from moisture-related voids. We’ve seen this happen when barrel temperatures are set too high or cycle times are unnecessarily long.

Venting and Trapped Air

If the material is properly dried and the temperature is correct, the problem may be mechanical. Inadequate mold venting traps air in the cavity. This compressed air can cause defects that mimic moisture issues or result in burn marks at the end of the fill path.

| Symptom | Probable Cause | Recommended Action |

|---|---|---|

| Streaks radiating from the gate | Moisture | Verify dryer temperature and time. |

| Bubbles inside the thickest section | Material Degradation | Lower barrel temperature or reduce residence time. |

| Splay marks at the end of fill | Trapped Air / Poor Venting | Check mold vents for blockage or size. |

Solving these common polycarbonate molding defects requires a methodical process. By addressing moisture control, thermal management, and proper mold venting, you can eliminate most splay marks and silver streaks in Makrolon parts, ensuring high-quality results and keeping projects on schedule.

Authenticity and Traceability: Ensuring Genuine Makrolon in Global Trials

In global mold trials, the risk of using unapproved "local equivalents" is a significant concern. A supplier might offer a generic polycarbonate, claiming it’s the same as Makrolon. This shortcut introduces unpredictable variables that can compromise the entire project’s integrity.

The Problem with Unverified Materials

Using a non-specified material can lead to failed tests and inaccurate data. The physical properties might not match, causing issues with part performance, dimensional stability, or appearance. This undermines the purpose of the trial, which is to validate the mold with the final production material.

Genuine Makrolon vs. Generic PC

It’s critical to understand the difference. Authentic Makrolon from Covestro has specific performance characteristics that generic materials often fail to replicate.

| Feature | Genuine Makrolon | Generic Polycarbonate |

|---|---|---|

| Consistency | Batch-to-batch reliability | Varies by supplier |

| Performance | Meets exact specifications | Often deviates |

| Traceability | Fully documented | Limited or none |

The Role of a Certificate of Analysis (COA)

The single most important document for material verification is the Certificate of Analysis (COA). It is the definitive proof of a resin’s identity, lot number, and compliance with specifications. At MTM, we always insist on providing a complete resin COA verification for every batch.

How to Verify Your Resin

A COA is more than just a piece of paper. It’s a guarantee. It contains critical data like melt flow rate, density, and other properties. This data confirms you are working with authentic Covestro resin, not a cheap substitute. We often use advanced methods to double-check these properties for our clients.

Critical Information on a COA

- Manufacturer’s Name: Should clearly state Covestro.

- Product Grade: Must match the specified Makrolon grade.

- Lot Number: Essential for complete material traceability.

- Test Results: Key physical properties must be within the specified range.

This level of verification is standard practice for us. Advanced analysis like Spectroscopy8 can even be used to confirm the unique chemical fingerprint of a polymer, leaving no room for doubt about its authenticity.

Ensuring material authenticity is non-negotiable for successful global trials. Always demand a Certificate of Analysis to verify you are using genuine Makrolon. This simple step protects your project from costly delays and failures caused by counterfeit or incorrect materials.

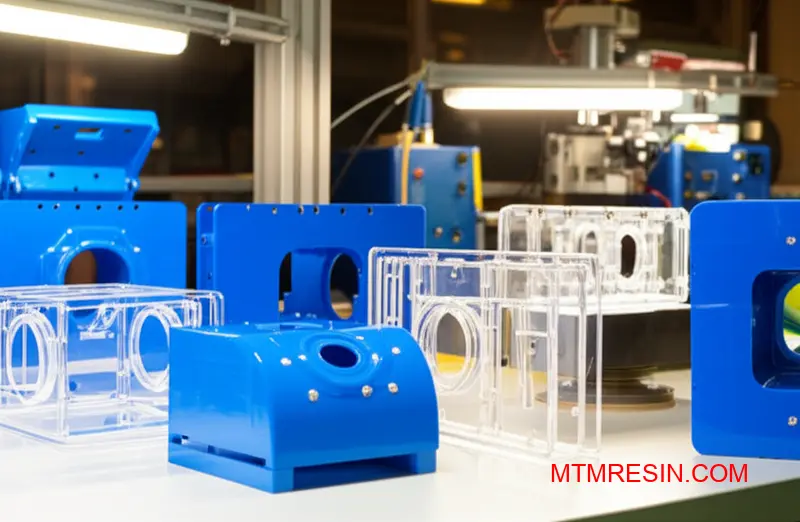

Equivalent Materials vs. Specified Brand: When to Substitute

Deciding between a specified brand and an equivalent material is a critical choice in mold trialing. When a project specifies a premium polycarbonate like Makrolon, sourcing it in China can cause delays. For initial T1 trials, the goal is often to verify mold geometry and basic functionality.

Is an Equivalent Acceptable for T1?

For early-stage trials, a high-quality local equivalent with a comparable datasheet is often sufficient. This approach allows you to check for fit, form, and mechanical action without waiting for costly international shipments. It accelerates the initial feedback loop significantly.

Key Decision Factors

The decision depends on the trial’s objective. A simple comparison can guide your choice.

| Trial Stage | Primary Goal | Recommended Material |

|---|---|---|

| T1 (First Shot) | Verify mold function, dimensions | Equivalent PC |

| T2 (Refinement) | Optimize processing parameters | Equivalent or Specified Brand |

| Final Validation | Certify product performance | Specified Brand (Makrolon) |

While datasheets provide a starting point, they don’t capture the full picture. Material substitution risks often lie in subtle differences that are not immediately obvious. These can include variations in processing additives, batch-to-batch consistency, and long-term performance under stress.

Beyond the Datasheet

A specified brand like Makrolon ensures consistent molecular structure and properties. Polycarbonate is an Amorphous9 polymer, meaning its performance is tied to its internal structure. An equivalent might match on paper but behave differently under real-world molding pressures and temperatures.

A Framework for Validation

At MTM, we guide clients through a practical validation process for Makrolon equivalents. This involves a direct comparison focusing on critical-to-quality attributes.

Critical Comparison Points

When substituting, we analyze potential deviations that could impact the final product. Even minor differences in material behavior can affect the outcome of your mold trial and subsequent validation.

| Attribute | Specified Makrolon | Potential Equivalent Risk |

|---|---|---|

| Shrinkage | Consistent and predictable | Higher variability, affecting tolerances |

| Melt Flow | Stable across batches | Can vary, requiring process adjustments |

| Optical Clarity | High and uniform | May have slight haze or color shifts |

Using equivalent materials for initial T1 trials accelerates mold validation by reducing wait times. However, for final performance and regulatory sign-off, using the specified brand like Makrolon is non-negotiable. The key is knowing when each approach is appropriate for your project timeline.

Secondary Operations: Painting, Bonding, and Welding Makrolon Parts

After molding, your Makrolon parts often need finishing touches. Secondary operations like painting, bonding, and welding are critical for both aesthetics and function. However, not all methods are suitable for every grade of Makrolon polycarbonate. Planning these steps from the design phase is essential.

Initial Process Selection

Choosing the right secondary process depends entirely on your application’s requirements. For instance, painting enhances appearance and UV resistance, while welding provides strong structural joints. You must consider the specific stresses the final part will endure. Neglecting this can lead to part failure.

| Operation | Primary Goal | Key Challenge |

|---|---|---|

| Painting | Aesthetics, UV Protection | Adhesion, Solvent Compatibility |

| Bonding | Assembly, Sealing | Adhesive Selection, Surface Prep |

| Welding | Structural Joints | Material Grade, Joint Design |

Matching Grade to Process

Different Makrolon grades respond differently. For example, a grade designed for medical devices may not accept certain paints due to surface chemistry. This is why material selection is so important. At MTM, we help clients source the exact grade needed for their entire process, not just molding.

Ultrasonic Welding Makrolon

Ultrasonic welding is a popular method for joining Makrolon components. It uses high-frequency vibrations to create a solid-state weld. However, the success of this process heavily depends on the joint design, the grade of Makrolon used, and the equipment settings.

Impact of Fillers

Glass-filled or mineral-filled Makrolon grades can be challenging to weld ultrasonically. The fillers can interfere with the polymer flow at the joint interface, leading to a weaker bond. In these cases, adjusting the weld time and pressure is critical to achieve optimal results.

Solvent Bonding Risks

Solvent bonding is another common technique, but it carries significant risks if not done correctly. Certain solvents can induce environmental stress cracking, which compromises the part’s long-term integrity. The material’s Viscoelasticity10 affects how it responds to the combined chemical and mechanical stress.

Here is a quick comparison of common joining methods for PC components.

| Method | Strength | Speed | Material Constraint |

|---|---|---|---|

| Ultrasonic Welding | High | Fast | Best for unfilled grades |

| Solvent Bonding | Moderate | Moderate | High risk of stress cracking |

| Adhesives (Epoxy/Cyanoacrylate) | Varies | Slow | Requires surface preparation |

Ultimately, choosing the right joining method requires a deep understanding of the specific Makrolon grade. Sourcing the correct material for your mold trial ensures that your post-molding tests will accurately reflect final production performance, preventing costly surprises down the line.

Choosing the correct Makrolon grade is crucial for successful secondary operations. Proper planning for painting, bonding, or ultrasonic welding prevents costly failures and ensures part integrity. These details matter from the earliest stages of product design and material selection.

Unlock Makrolon Trial Speed with MTM Solutions

Looking for Makrolon grades for your next injection molding trial in China? Streamline your project—request a quote from MTM and get immediate access to authentic, pre-stocked Makrolon materials. Skip overseas shipping and delays. Contact us today to guarantee consistency, compliance, and rapid trial success!

-

Understand this polymer type’s behavior under heat, crucial for injection molding process optimization. ↩

-

Understand how this chemical process affects long-term durability and product aesthetics. ↩

-

Understanding this is crucial for developing safe medical devices that interact with biological systems. ↩

-

Understanding this char-forming mechanism helps select advanced flame retardant systems for high-temperature applications. ↩

-

Understanding this property helps engineers minimize optical distortion in molded lenses and transparent components. ↩

-

Understanding this concept helps predict material flow and optimize molding for complex parts. ↩

-

Understanding this material property is fundamental to preventing moisture-related defects in many engineering polymers. ↩

-

Learn how this analytical technique confirms polymer composition, ensuring material authenticity. ↩

-

Understanding this structure helps predict material behaviors like transparency and shrinkage during the molding process. ↩

-

Understanding this property helps predict how Makrolon will respond to welding heat and pressure. ↩