Finding authentic Duracon POM in China can feel like searching for a needle in a haystack. You’ve spent weeks coordinating with suppliers, only to receive questionable certificates and conflicting specifications that put your entire mold trial timeline at risk.

Duracon POM is a copolymer acetal resin series manufactured by Polyplastics, offering superior chemical resistance and dimensional stability compared to homopolymer alternatives. Key grades include standard M90, high-flow M25, and reinforced variants like GH-25, each engineered for specific molding applications and part geometries.

I’ve worked with engineering teams across different industries who face the same challenge when selecting the right Duracon grade for their China trials. The technical differences between grades can make or break your part performance, and getting authentic material is just the beginning. Let me walk you through the critical factors that will help you make the right choice for your specific application.

Decoding the Duracon Series: Selecting the Core Grade

Choosing the right Duracon POM grade can feel complicated. The nomenclature, however, is straightforward once you understand the core series. Each grade is tailored for specific performance needs, from standard applications to complex geometries requiring unique material properties. It is a critical first step.

Understanding the Core Grades

The most common grades you’ll encounter are M90 and M25. They serve as the foundation of the Duracon series. M90 is the standard, general-purpose grade, offering a balanced profile. M25, on the other hand, is a high-flow variant designed for intricate parts.

Quick Grade Comparison

| Grade | Primary Characteristic | Common Use Case |

|---|---|---|

| M90-44 | Standard Flow/Balanced | General mechanical parts |

| M25-44 | High Flow | Thin-walled components |

Selecting between them often comes down to your part’s design. At MTM, we stock these core grades to ensure your mold trials in China can proceed without delay.

The choice between Duracon M90 and M25 is a classic trade-off between mechanical strength and processability. While M90 provides excellent all-around performance, its standard viscosity can be challenging for molds with long flow paths or very thin wall sections. This is where M25 becomes essential.

Performance vs. Processability

The higher melt flow of Duracon M25 allows the resin to fill complex cavities more easily, reducing the risk of short shots or high injection pressures. However, this improved flow comes at a slight cost to mechanical properties like tensile strength and rigidity when compared directly to M90.

Beyond the Basics: High-Rigidity Grades

For applications demanding superior stiffness, such as structural components, you should consider high-rigidity grades. These are often glass-filled or mineral-filled variants. They offer significantly higher modulus but require different processing parameters. The material’s Crystallinity1 plays a key role in achieving these enhanced properties.

| Grade Type | Key Benefit | Ideal Application Geometry |

|---|---|---|

| Standard (M90) | Balanced properties | Gears, bushings, clips |

| High-Flow (M25) | Excellent mold filling | Housings, connectors, grilles |

| High-Rigidity | Maximum stiffness | Brackets, support frames |

Understanding your part’s functional requirements is key. Is it a simple gear or a complex, thin-walled housing? Answering this question simplifies your Duracon grade selection process significantly.

Selecting the correct Duracon grade involves balancing part geometry, mechanical requirements, and processing ease. Standard M90 offers balanced properties, while high-flow M25 suits complex parts, and rigid grades provide stiffness for structural applications. Proper selection streamlines production and ensures performance.

Analysis of Duracon Mechanical Properties and Tribology

Duracon, a leading polyoxymethylene (POM), is a cornerstone material for high-performance engineering components. Its excellent balance of stiffness, fatigue endurance, and dimensional stability makes it a prime candidate for precision parts. At MTM, we frequently supply various grades of Duracon for intricate mold trials.

Key Mechanical Strengths

This material excels in applications that demand consistent performance under mechanical stress. Its inherently low moisture absorption ensures that components maintain their intended shape and strength. This is a critical factor for many client projects where environmental conditions can vary.

Core Property Overview

We have verified that its properties provide a reliable foundation for design engineers. The material’s behavior is predictable across a range of operational temperatures.

| Property | Typical Value | Significance for Design |

|---|---|---|

| Tensile Strength | 60 – 70 MPa | High load-bearing capacity |

| Flexural Modulus | 2600 – 2900 MPa | Resists bending and deformation |

| Water Absorption (24hr) | < 0.22% | Ensures dimensional stability |

Tribological Performance in Gears and Moving Parts

When designing gears, bearings, or sliders, friction and wear are primary concerns. The acetal mechanical properties of Duracon make it a self-lubricating plastic. This inherent lubricity results in a very low Duracon friction coefficient, especially against metals and other plastics, reducing the need for external lubricants.

This excellent POM wear resistance extends the service life of components. In many applications I’ve consulted on, replacing metal parts with Duracon not only reduces weight but also minimizes system maintenance. It withstands repetitive motion without significant material degradation.

Noise Reduction and Smooth Operation

A key benefit over metals is noise reduction. Metal-on-metal contact often generates significant operational noise and vibration. Duracon’s composition dampens these effects, leading to quieter and smoother machine operation. This helps avoid issues like the Stick-slip phenomenon2, ensuring consistent motion.

Duracon vs. Steel Comparison

The choice between Duracon and metal often comes down to specific application demands. Based on our tests, the comparison is quite clear for low-to-medium load scenarios.

| Feature | Duracon (POM) | Carbon Steel |

|---|---|---|

| Density | Low | High |

| Friction | Naturally Low | High without lubricant |

| Noise Level | Dampens Sound | Transmits Sound |

| Corrosion Resistance | Excellent | Poor (Requires Coating) |

Duracon offers a compelling combination of mechanical strength and superior tribological properties. Its self-lubricating nature, wear resistance, and noise-dampening capabilities provide a distinct advantage over metals for gears and other moving parts, enhancing efficiency and component longevity in many engineering applications.

High-Flow vs. Standard: When to Specify Duracon M25 or M90

Choosing between Duracon M25 and M90 acetal is a frequent decision for engineers. The primary difference lies in their melt flow rate. Duracon M25 is a high-flow grade, perfect for complex, thin-walled components. Its lower viscosity allows it to fill intricate mold cavities easily.

In contrast, Duracon M90 is the standard, lower-flow grade. It provides excellent mechanical strength and is better suited for thicker, structural parts where dimensional stability is key. Understanding this distinction is the first step in material selection.

Key Differences at a Glance

| Feature | Duracon M25 (High-Flow) | Duracon M90 (Standard) |

|---|---|---|

| Melt Flow Rate (MFR) | High | Standard |

| Primary Application | Thin-wall, complex parts | Thick, structural parts |

| Injection Pressure | Lower | Higher |

| Cycle Time | Potentially faster | Standard |

Deeper Dive into Processing and Performance

While Melt Flow Rate (MFR) is the main differentiator, the implications run deeper. The high flow of Duracon M25 can lead to shorter cycle times, a significant advantage in high-volume production. This is because the mold fills faster with less injection pressure.

However, this property demands precise process control. High-flow materials are more susceptible to flashing if the mold and process are not optimized. The study of Rheology3 helps us understand these flow characteristics. M90, with its higher viscosity, offers a wider processing window and is more forgiving, making it a robust choice.

Mechanical and Project Considerations

A common question I get is whether high flow compromises strength. For Duracon M25, there can be a slight trade-off in impact strength compared to M90. It’s a factor to consider for parts subjected to high stress or impact.

At MTM, we stock both Duracon grades in China. This allows our clients to conduct mold trials with both materials quickly. They can validate their choice without waiting for overseas shipments, ensuring the final part meets both processing and performance requirements.

| Property Trade-off | Duracon M25 (High-Flow) | Duracon M90 (Standard) |

|---|---|---|

| Processing Window | Narrower | Wider |

| Impact Strength | Good | Excellent |

| Suitability for Regrind | Good | Excellent |

The decision between Duracon M25 and M90 depends on your part’s geometry and performance needs. M25 excels in speed and intricate designs, while M90 provides robustness for structural applications. Evaluating these trade-offs early is key to a successful project.

Reinforced Duracon: Glass Fiber and Mineral Filled Options

When standard POM isn’t enough, reinforced Duracon grades step in. Adding glass fibers or minerals dramatically changes the material’s properties, enhancing stiffness and strength for more demanding applications. This is crucial for parts that need to withstand high loads without deforming.

Why Reinforce Standard Duracon?

Standard Duracon is known for its low friction and good chemical resistance. However, for structural components, its stiffness can be a limiting factor. Reinforcement directly addresses this, creating a more robust material suitable for metal replacement projects.

Key Reinforcement Types

The two most common fillers are glass fiber and minerals. Each offers a different balance of properties. Here’s a quick comparison based on our lab findings.

| Property | Standard POM | Glass Filled POM | Mineral Filled POM |

|---|---|---|---|

| Rigidity | Moderate | Very High | High |

| Warpage | Low | High | Moderate |

| Surface Finish | Excellent | Fair | Good |

| Cost | Baseline | Higher | Moderate |

When clients ask for reinforced POM, they often mention specific grades like Duracon GH-25. The designation itself tells a story: "G" for glass fiber and "25" for the 25% fill percentage. This grade offers a significant boost in structural rigidity over unfilled POM.

However, there’s a critical trade-off to consider: warpage. The orientation of glass fibers during molding creates uneven shrinkage. This Anisotropy4 is a primary cause of part distortion, especially in flat, thin-walled designs. Proper gate location and mold design are essential to manage this effect.

Glass Fiber vs. Mineral Fillers

While glass fibers provide maximum stiffness, mineral fillers offer a compromise. They improve rigidity and dimensional stability but with less tendency to warp. The choice depends entirely on the application’s specific mechanical and aesthetic requirements.

| Filler Type | Primary Benefit | Main Challenge | Best For |

|---|---|---|---|

| Glass Fiber (e.g., GH-25) | Maximum Stiffness & Strength | High Warpage Potential | Structural Frames, Levers |

| Mineral Filled | Good Stiffness, Low Warpage | Lower Impact Strength | Housings, Flat Panels |

At MTM, we often supply both types for mold trials, allowing engineers to see firsthand how each reinforced Duracon performs. This direct comparison is invaluable for making the right material choice.

Reinforced Duracon grades like GH-25 offer enhanced rigidity for structural parts. However, this performance comes with design and processing challenges, especially managing warpage from fiber orientation. Choosing the right filler is key to balancing stiffness with dimensional stability.

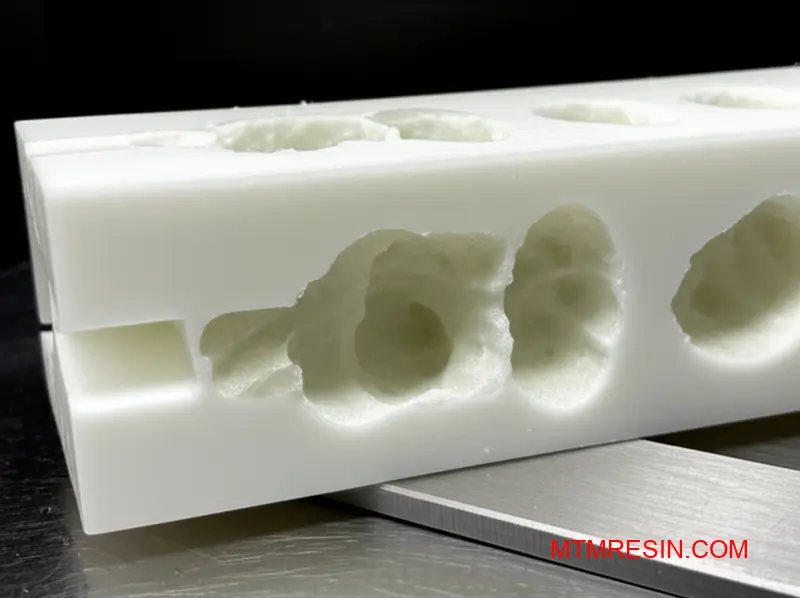

Troubleshooting Voids and Vacuum Bubbles in Thick Sections

Voids in thick-walled parts, especially when using POM like Duracon, are a frequent challenge. Distinguishing between gas traps and vacuum voids is the first step. Gas traps have smooth, shiny surfaces, while vacuum voids are irregular and rough, caused by material shrinkage.

Identifying the Defect Type

Understanding the visual cues is critical. Gas traps occur when air or volatiles are trapped, while vacuum voids form as the material cools and shrinks away from the center. This distinction dictates the troubleshooting approach you should take for a successful outcome.

Visual Comparison: Voids vs. Gas Traps

| Feature | Vacuum Void | Gas Trap (Bubble) |

|---|---|---|

| Appearance | Irregular, rough surface | Smooth, spherical, shiny surface |

| Location | Core of thick sections | Near end-of-fill, weld lines |

| Cause | Material shrinkage | Trapped air or gas |

Proper diagnosis prevents wasting time on incorrect solutions. Addressing shrinkage for a gas trap problem will not work. That is why identifying the root cause is so important before adjusting any machine parameters.

Solving these issues involves adjusting both the mold design and the injection process. The solutions for voids and gas traps are often opposites. For instance, increasing back pressure can help with gas traps but may worsen voids if not balanced correctly with other parameters.

Processing Solutions for Vacuum Voids

When dealing with true vacuum voids in materials like Duracon, the primary goal is to pack more material into the cavity before the gate freezes. This counteracts the natural Volumetric Shrinkage5 that occurs during cooling. The gate must remain open long enough for holding pressure to be effective.

Key Parameter Adjustments

Adjusting processing parameters is the most direct way to combat voids. We’ve found that a systematic approach, focusing on pressure and time, yields the best results. A small change in one area can have a significant impact on the final part quality.

| Parameter | Recommended Action | Rationale |

|---|---|---|

| Holding Pressure | Increase | Forces more material into the cavity to compensate for shrinkage. |

| Holding Time | Increase | Ensures pressure is applied until the gate freeze-off time is reached. |

| Melt Temperature | Decrease slightly | Reduces overall shrinkage, but can increase viscosity. |

| Gate Size | Increase (Mold Mod) | Delays gate freeze-off, allowing for a longer packing window. |

At MTM, we often advise clients to focus first on holding pressure and time. These are the most powerful tools for troubleshooting voids in thick sections of POM. Modifying the mold’s gate size is a more involved step, but often necessary for parts with very thick sections.

Effectively troubleshooting voids and bubbles in thick sections requires correctly identifying the defect first. Then, systematically adjust processing parameters like holding time and pressure to ensure proper packing before the gate freezes, especially when using materials like Duracon.

Creep Resistance and Long-Term Load Bearing Capacity

For engineers designing clips and springs, material performance under constant load is crucial. Duracon POM is a leading choice for these applications due to its excellent creep resistance. This ensures parts like snap-fit connectors maintain their holding force over time without deforming.

Constant Load Performance

Under sustained stress, many plastics will slowly deform. This phenomenon, known as creep, can lead to failure in load-bearing applications. Duracon’s crystalline structure, however, minimizes this effect, providing reliable long-term stability for critical components. We often recommend it for this reason.

Key Material Properties

Here is a simplified comparison of creep performance.

| Property | Duracon POM | General-Purpose ABS |

|---|---|---|

| Creep Modulus | High | Moderate |

| Deformation Under Load | Low | High |

| Long-Term Reliability | Excellent | Fair |

This table highlights why selecting the right material, like Duracon, is fundamental for durable designs.

Beyond static loads, many components like clips and fasteners endure repeated stress cycles. This is where understanding fatigue endurance becomes essential. Duracon excels not only in creep resistance but also in its ability to withstand repetitive loading without failure.

Fatigue and Endurance Limits

A material’s fatigue limit is the stress level below which it can withstand a very large number of loading cycles. Our tests show Duracon possesses a high plastic fatigue limit6, making it an ideal snap-fit design material. This property is vital for parts that are frequently assembled and disassembled.

Designing for Cyclic Loads

When I work with design engineers, we often discuss the expected lifecycle of a part. For a snap-fit that will be used daily, the material must resist fatigue. Duracon’s performance in these scenarios prevents premature cracking or loss of function.

| Application Factor | Design Consideration | Recommended Material |

|---|---|---|

| High Cycle Count | High Fatigue Endurance | Duracon |

| Constant Pressure | High Creep Modulus | Duracon |

| Precision Fit | Dimensional Stability | Duracon |

Choosing a material with a predictable fatigue life is key to creating a reliable product. This is a core part of the material selection support we provide at MTM, ensuring your parts meet performance requirements from the start.

Duracon’s high creep modulus and fatigue endurance make it a top-tier material for clips, springs, and snap-fit designs. Its reliability in long-term, load-bearing applications ensures component integrity and prevents premature failure, offering predictable performance for engineers.

Low VOC and Low Odor Duracon Grades for Automotive Interiors

The automotive industry has increasingly strict standards for cabin air quality. Volatile Organic Compounds (VOCs) from interior plastics can cause unpleasant odors and health concerns. This has driven the demand for specialized low-VOC POM materials that meet these tough requirements.

Understanding the Need for Low VOC Materials

Car manufacturers must comply with global regulations on interior air quality. Materials used in dashboards, vents, and clips are under scrutiny. Standard plastics can release chemicals, particularly formaldehyde, which is why specialized grades are now essential for modern vehicle design.

Introducing Duracon’s Solution

The Duracon LV series is engineered specifically to address these challenges. These grades offer significantly lower VOC and formaldehyde emissions compared to conventional POM.

| Feature | Standard POM | Duracon LV Series |

|---|---|---|

| VOC Emission | Standard Levels | Significantly Reduced |

| Formaldehyde | Higher Potential | Meets Strict Limits |

| Application | General Purpose | Automotive Interiors |

These specialized materials ensure that components pass rigorous automotive interior specifications without compromising mechanical performance, a critical factor for project success.

Deep Dive into Automotive Specifications

When a client approaches us at MTM for an automotive project, their primary concern is meeting specific OEM standards. These specifications set firm limits on emissions from plastic components. Failing these tests during a mold trial can cause significant project delays and costs.

Formaldehyde Emission Limits

Formaldehyde is a key VOC targeted by regulations. The Duracon LV series is specifically formulated to keep these emissions well below the required thresholds. Based on our tests with clients, these grades consistently perform well in chamber emission tests required by major automotive brands.

The Process of Outgassing7

The release of trapped gasses from a plastic part is a natural process. However, in a confined space like a car cabin, this can lead to high concentrations of VOCs. Low-VOC POM grades like Duracon are designed to minimize this effect through specialized polymer chemistry and manufacturing processes.

| Standard | Target VOC | Duracon LV Compliance |

|---|---|---|

| VDA 275 | Formaldehyde | Excellent |

| VDA 277 | Odor | Excellent |

| VDA 278 | VOC/FOG | Excellent |

Selecting the correct grade is crucial. We help clients navigate these complex requirements, providing the right Duracon material from our stock in China to ensure their initial mold trials produce parts that pass certification.

Low-VOC and low-odor Duracon grades are essential for meeting modern automotive cabin air quality standards. The LV series is specifically designed to minimize emissions like formaldehyde, ensuring compliance with strict industry specifications and preventing costly project delays.

Medical and Food Contact Compliance Specs

When selecting materials for sensitive applications, compliance is non-negotiable. The Duracon POM portfolio offers specific grades that meet stringent regulatory standards. Understanding these is key for designers and engineers working on medical devices or food processing equipment to ensure product safety and market access.

Key Regulatory Standards

Navigating standards like FDA, NSF, and USP can be complex. Each serves a distinct purpose, from general food contact to invasive medical use. Choosing the right grade of Duracon from the start prevents costly redesigns and delays in your project timeline.

| Standard | Primary Focus Area | Common Application |

|---|---|---|

| FDA | Food Contact Safety | Food processing components, containers |

| NSF | Public Health & Safety | Drinking water systems, food equipment |

| USP Class VI | Biocompatibility | Medical devices, surgical instruments |

Why This Matters

Selecting a material without the proper certification can lead to immediate project failure. It’s not just about performance; it’s about adhering to legal and safety requirements. This ensures the final product is safe for consumer or patient use.

Differentiating Compliance Grades

It’s a common mistake to assume these certifications are interchangeable. An FDA-compliant grade of Duracon is not automatically suitable for a medical implant, for instance. The level of required testing and validation varies significantly between these standards.

FDA and NSF Grades

FDA compliance primarily covers materials that come into direct contact with food. NSF certification often goes a step further, testing the final product’s material formulation. For many food-grade applications, our clients find that standard Duracon FDA grades are perfectly suitable for their trial molds.

USP Class VI: The Medical Standard

USP Class VI is the gold standard for medical applications. It involves rigorous testing to assess the material’s biological reactivity in contact with living tissue. This ensures the material will not cause harm when used in or on the body. Understanding material Biocompatibility8 is absolutely essential here.

Based on our client discussions, choosing a USP Class VI resin is a critical decision point for any medical device prototype. It ensures the trial results are relevant for the final production part.

| Duracon Grade Type | Ideal For | Key Consideration |

|---|---|---|

| Duracon FDA Compliance | Food processing machinery parts | Material must meet CFR 21 regulations |

| Medical Grade Acetal | Reusable medical instruments | Must withstand sterilization cycles |

| USP Class VI Resin | Short-term bodily contact devices | Requires extensive biological testing |

At MTM, we stock these specific grades in China, so you can conduct your trials without waiting for overseas shipments. This greatly accelerates the validation process for our clients’ critical projects.

Choosing the correct certified Duracon grade—whether FDA, NSF, or USP Class VI—is crucial for product safety and regulatory success. This decision directly impacts your project’s viability, ensuring the material is appropriate and safe for its intended end-use environment.

Equivalent Materials: When to Substitute Duracon for Delrin

Choosing between Delrin and Duracon involves more than just checking a data sheet. While both are acetals (POM), their core structures—homopolymer versus copolymer—dictate performance. Understanding these differences is key to a successful material substitution for your project.

Key Material Differences

Delrin (homopolymer) typically offers slightly higher stiffness and strength. However, Duracon (copolymer) provides better thermal stability and chemical resistance, which are critical factors during processing and in the final application environment. This makes a Duracon equivalent a strong contender.

Initial Comparison

| Feature | Delrin (Homopolymer) | Duracon (Copolymer) |

|---|---|---|

| Structure | Higher Crystallinity | Lower Crystallinity |

| Mechanicals | Higher Stiffness/Strength | Better Impact/Fatigue |

| Processing | Narrower Window | Wider Window |

| Thermal | Lower Stability | Higher Stability |

This initial look shows a clear trade-off between mechanical properties and processability.

Processing Stability and Part Integrity

The wider processing window of Duracon is a significant advantage. It is more forgiving of temperature variations in the mold, reducing the risk of thermal degradation. This makes it a more robust choice for complex geometries or demanding molding conditions.

The Challenge of Centerline Porosity

Delrin’s rapid solidification rate can sometimes trap gas, leading to centerline porosity, especially in thicker sections. This internal void can compromise structural integrity. In our experience with client trials, Duracon’s slower, more controlled crystallization often yields parts with better internal consistency.

Long-Term Performance Considerations

Beyond processing, environmental factors matter. Copolymers like Duracon exhibit superior resistance to degradation from hot water and alkaline solutions. This is due to their chemical structure, which is less susceptible to Hydrolysis9. For applications exposed to such conditions, substituting Delrin with a Duracon equivalent can prevent premature failure.

Property Trade-Off Summary

| Property Focus | Recommended Material | Justification |

|---|---|---|

| Maximum Stiffness | Delrin | Higher modulus and tensile strength. |

| Thermal Processing | Duracon | Wider temperature window, less risk of degradation. |

| Chemical Resistance | Duracon | Better performance in alkaline and hot water environments. |

| Thick-Walled Parts | Duracon | Reduced risk of internal voids and porosity. |

At MTM, we stock both materials, allowing you to conduct side-by-side trials in China to confirm the best fit for your specific mold.

While Delrin provides higher mechanical strength, Duracon offers superior thermal stability and a wider processing window. This makes Duracon a safer choice for parts with complex geometries or those exposed to harsh chemical environments, effectively reducing molding risks.

Verifying Material Authenticity in the Chinese Supply Market

The risk of counterfeit materials in China is a valid concern for many clients. When dealing with high-performance materials like Duracon, authenticity is non-negotiable. The first step in verification always involves checking the documentation and packaging.

Initial Verification Checks

Your primary tools are the Certificate of Analysis (COA) and the bag markings. A genuine COA should match the details on the packaging exactly. Any discrepancy is a major red flag. This initial check can prevent significant issues down the line.

Key Areas to Inspect

Pay close attention to the lot number, grade, and manufacturer details. We’ve seen cases where these simple items don’t align, immediately exposing a fake Duracon risk.

| Document | Key Checkpoints |

|---|---|

| COA | Lot Number, Test Data, Manufacturer Seal |

| Bag | Printed Lot Number, Branding, Sealing |

At MTM, we handle this scrutiny for you, guaranteeing only authentic resin reaches your mold trial.

Beyond the Paperwork

A convincing COA can still be fraudulent. True material COA verification requires a deeper look. We advise clients to cross-reference lot numbers with the original manufacturer whenever possible. For example, a Polyplastics lot number has a specific format that experienced handlers recognize.

Advanced Verification Steps

Counterfeiters often replicate packaging, but small details give them away. Look for inconsistencies in print quality, bag material texture, and how the bag is sealed. These subtle clues are often missed by untrained eyes but are a core part of our internal auditing process. True Traceability10 is key.

This rigorous process is how we ensure you receive authentic resin in China. We don’t just take the supplier’s word for it; we verify it.

| Feature | Authentic Material | Potential Counterfeit |

|---|---|---|

| Print Quality | Crisp, clear, uniform | Blurry, inconsistent ink |

| Lot Number | Matches COA, correct format | Mismatched, unusual format |

| Bag Seal | Factory-standard heat seal | Irregular, re-sealed look |

Our commitment at MTM is to eliminate these risks. We source directly from trusted channels, and our pre-stocked materials, like Duracon, have already passed these stringent checks. You can proceed with your mold trial confidently.

Verifying a material’s COA and packaging is your first defense against counterfeit risks. At MTM, our multi-step authentication process ensures every material, including Duracon, is genuine, protecting your project’s integrity and timeline in China.

Level Up Your China Trials—Choose MTM for Duracon POM

Struggling to source the right Duracon grade in China or worried about authenticity, performance, and trial deadlines? Contact MTM now for fast, reliable delivery of pre-stocked Duracon POM materials—genuine, verified, and ready for your mold trial. Send us your inquiry for a quick quote today!

-

Understanding this concept helps predict the material’s final mechanical strength and dimensional stability. ↩

-

Understanding this concept helps in designing quieter, smoother mechanical systems and preventing unwanted vibrations. ↩

-

This field of study helps predict material behavior and optimize the injection molding process for part quality. ↩

-

Understanding this helps predict and control part warpage in fiber-reinforced materials. ↩

-

Understanding this helps predict material behavior and optimize part packing during the molding cycle. ↩

-

Understanding this limit helps predict component lifespan under repeated stress. ↩

-

Learn how this material property influences component compliance with air quality regulations. ↩

-

Understanding this concept is crucial for developing safe and effective medical devices. ↩

-

Understanding this chemical process helps predict long-term part performance in demanding environments. ↩

-

Understanding traceability helps secure supply chains and verify product authenticity from origin to delivery. ↩