Finding the right technical specifications for Akulon K224-G6 can feel overwhelming when you’re racing against project deadlines. You’ve probably experienced the frustration of incomplete datasheets or conflicting processing parameters that leave your molding trials in uncertainty.

Akulon K224-G6 is a 30% glass fiber reinforced PA6 engineering plastic that delivers exceptional stiffness, thermal stability, and dimensional precision for demanding automotive and industrial applications requiring consistent mechanical performance.

Getting K224-G6 specifications right is just the first step. The real challenge often comes when you need the material in China for mold trials, where sourcing authentic grades can become a project bottleneck that delays your entire development timeline.

Unlocking High Performance: Why Engineers Specify Akulon K224-G6

Engineers frequently specify Akulon K224-G6 for demanding applications because it offers a reliable balance of properties. As a 30% glass-fiber reinforced Polyamide 6 (PA6-GF30), it provides a predictable combination of stiffness, strength, and thermal resistance without being overly difficult to process during injection molding.

A Reliable Engineering Choice

This material is a true workhorse. Its formulation ensures that parts can withstand mechanical stress and elevated temperatures, making it a go-to for automotive, industrial, and consumer goods. Its processability allows for consistent production, which is critical for complex geometries.

Key Performance Attributes

Here is a quick overview of what makes Akulon K224-G6 stand out.

| Property | Benefit |

|---|---|

| High Stiffness | Glass fiber reinforcement provides excellent structural integrity. |

| Heat Resistance | Maintains mechanical properties at elevated temperatures. |

| Processability | Offers a good molding window for consistent results. |

| Durability | Exhibits strong resistance to wear, fatigue, and chemicals. |

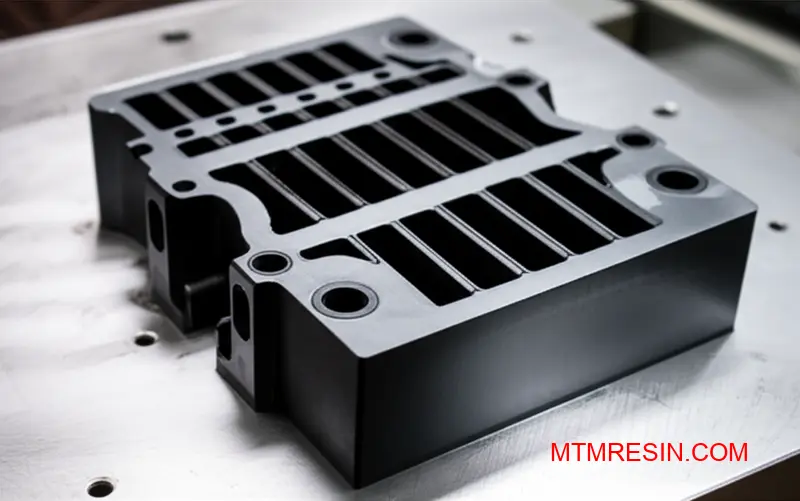

While datasheets provide a great starting point, real-world performance is what truly matters. For engineers conducting mold trials in China, sourcing the exact Akulon K224-G6 grade is crucial. Using an equivalent can skew test results, leading to costly redesigns. At MTM, we stock this specific material locally to prevent such issues.

Moisture and Dimensional Stability

One critical factor with any PA6 material is its tendency to absorb moisture. This characteristic, known as Hygroscopy1, can alter the material’s dimensional and mechanical properties after molding. Parts may swell slightly in humid environments, an effect engineers must account for during the design phase to maintain tight tolerances. Proper pre-drying of the resin is essential before processing.

Processing Considerations

Akulon K224-G6 has a relatively wide processing window, but success depends on precise control. The glass fibers can also lead to anisotropic shrinkage, meaning the part shrinks differently along the flow path versus across it. This requires careful mold design to manage potential warpage.

| Parameter | Akulon K224-G6 (PA6-GF30) | Standard PA6 (Unfilled) |

|---|---|---|

| Molding Shrinkage | Lower, Anisotropic | Higher, Isotropic |

| Tensile Strength | Significantly Higher | Lower |

| Warpage Potential | Higher if not controlled | Lower |

| Surface Finish | Less Smooth (fibers visible) | Smooth, Glossy |

Akulon K224-G6 is a preferred engineering thermoplastic due to its balanced profile of stiffness, heat resistance, and processability. This reliability makes it ideal for demanding applications and validating mold performance, ensuring predictable results when the specified grade is used.

Critical Physical Properties: Understanding the 30% Glass Fiber Advantage

When selecting a material for a structural application, adding 30% glass fiber to a polymer base like PA6 is a common strategy. This isn’t just a random number; it represents a sweet spot for enhancing mechanical properties without making the material too difficult or expensive to process.

Enhanced Strength and Stiffness

The primary benefit is a significant jump in strength and stiffness. The glass fibers act as a reinforcement, carrying a large portion of the load applied to the part. This makes materials like Akulon K224-G6 suitable for demanding applications where unfilled polymers would fail.

Impact on Key Properties

| Property | Unfilled PA6 | PA6 with 30% Glass Fiber |

|---|---|---|

| Tensile Strength | Low | High |

| Stiffness (Flexural Modulus) | Low | Very High |

| Dimensional Stability | Fair | Excellent |

| Impact Resistance | Good | Moderate to High |

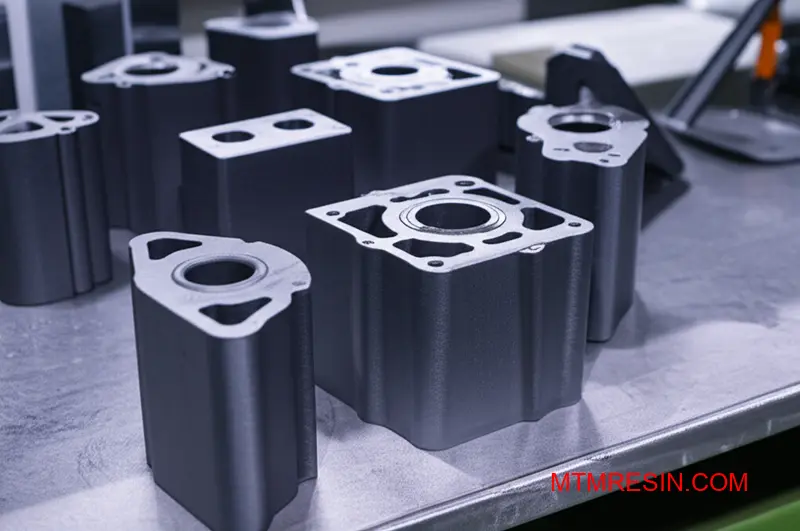

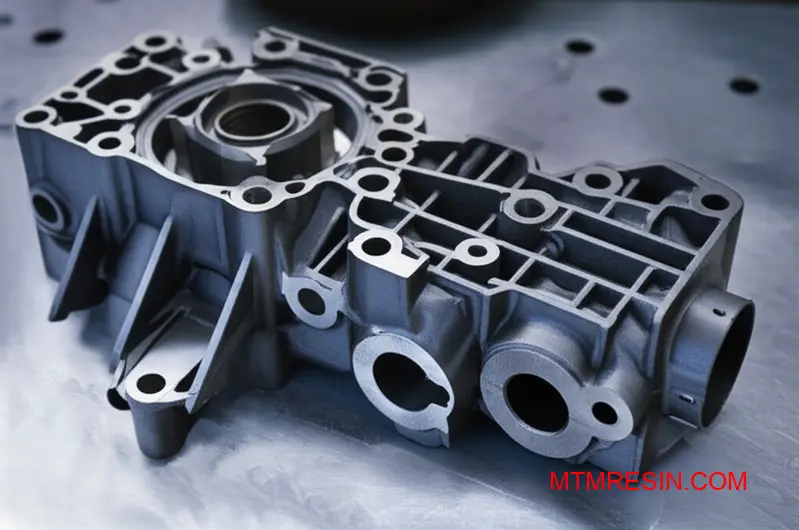

This reinforcement transforms the base resin into a high-performance engineering thermoplastic, ready for more challenging roles. We often see this specified for automotive brackets, industrial housings, and power tool components where reliability is critical.

When we examine a mechanical data sheet, the numbers clearly show the trade-offs involved. Let’s break down the most critical changes you see when moving from an unfilled PA6 to a 30% glass-reinforced grade like Akulon K224-G6.

A Deeper Look at the Data

Tensile Strength and Stiffness

The most dramatic improvement is in tensile strength. Unfilled PA6 might have a tensile strength around 80 MPa. With 30% glass fiber reinforcement, this value can easily double to over 180 MPa. This is because the fibers disrupt crack propagation and distribute stress across the material. The impact of fiber orientation, a property known as Anisotropy2, is also a critical factor here.

Elongation: The Trade-Off

This added strength comes at the cost of ductility. Unfilled PA6 is quite flexible, with a high elongation at break. The glass fibers, however, restrict the polymer chains from stretching. This drastically reduces elongation, making the material much more brittle.

Comparing Mechanical Data

| Mechanical Property | Unfilled PA6 (Typical) | Akulon K224-G6 (30% GF) |

|---|---|---|

| Tensile Strength (MPa) | ~80 | ~185 |

| Elongation at Break (%) | >50 | ~3 |

| Charpy Notched Impact (kJ/m²) | ~5 | ~12 |

As our test results confirm, the material becomes significantly stronger but less forgiving. Understanding this balance is essential for proper part design and material selection, preventing unexpected failures in the field.

Adding 30% glass fiber to PA6, as seen in Akulon K224-G6, transforms it into a high-strength, stiff material. This enhancement comes with reduced flexibility, a critical trade-off that engineers must consider for structural components requiring high load-bearing capacity and dimensional stability.

Thermal Stability & Heat Deflection: Performance Under Temperature Stress

When selecting materials for high-heat environments, understanding thermal performance is non-negotiable. It’s about more than just a melting point; it’s about how a material behaves under constant stress and elevated temperatures. This is especially true for parts used in automotive or industrial applications.

Key Thermal Metrics

For a material like Akulon K224-G6, we focus on specific data points that predict its real-world behavior. The Heat Deflection Temperature (HDT) tells us when it starts to soften under load, a critical factor for structural components.

Comparing Performance Data

Analyzing thermal properties requires a clear view of how different metrics relate. We’ve compared key values to illustrate the material’s operational limits.

| Thermal Property | Typical Value (°C) for Akulon K224-G6 | Application Relevance |

|---|---|---|

| Melting Point | ~255°C | Indicates phase change, not use limit |

| HDT (1.8 MPa) | ~245°C | Short-term deformation resistance |

| Continuous Use Temp | ~130°C | Long-term operational stability |

This data shows a significant gap between short-term endurance and long-term reliability. Relying solely on the melting point would lead to component failure.

When analyzing the thermal limits of Akulon K224-G6, it’s crucial to distinguish between different performance indicators. The Heat Deflection Temperature (HDT) and melting point are often reviewed, but they tell incomplete stories for demanding applications like those under the hood.

Beyond the Melting Point

The HDT value for Akulon K224-G6 is impressive, showing resistance to short-term deformation under load. This behavior is closely related to the polymer’s Glass Transition Temperature3, where the material shifts from a rigid to a more rubbery state. However, it is not a safe continuous operating limit.

Real-World Operating Conditions

For long-term reliability, the continuous use temperature is the most important metric. This value reflects the maximum temperature the material can withstand over its service life without significant loss of properties. At MTM, we always emphasize this figure when consulting on automotive projects.

| Metric | Short-Term Indication | Long-Term Reality |

|---|---|---|

| HDT | High stiffness under temporary heat | Not suitable for prolonged exposure |

| Melting Point | Complete material failure point | Irrelevant for design limits |

| Continuous Use | N/A | Defines safe operational envelope |

Focusing on the complete set of Akulon K224-G6 thermal properties ensures that parts maintain their integrity throughout their intended lifecycle, avoiding premature failure.

Understanding a material’s thermal properties, including HDT and continuous use temperature, is crucial. These metrics provide a realistic view of performance under stress, preventing component failure in demanding applications and ensuring long-term reliability for materials like Akulon K224-G6.

Dimensional Stability & Shrinkage: Precision in Tooling Design

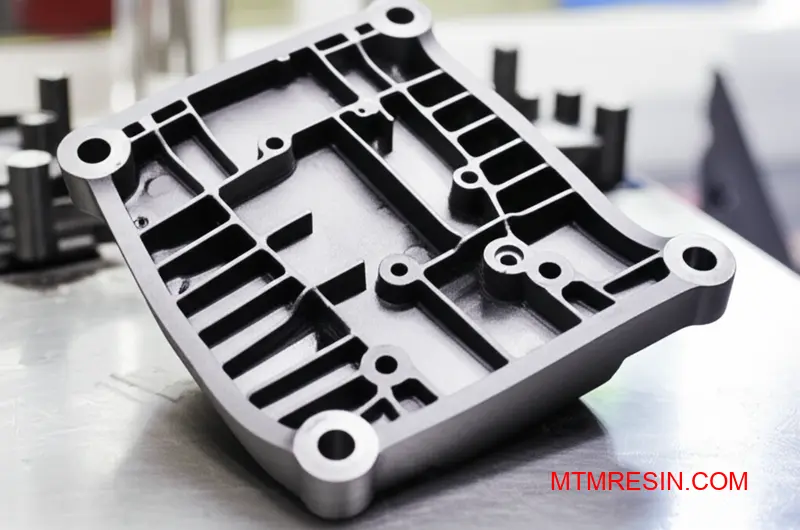

For mold designers, shrinkage is a constant challenge. With a material like Akulon K224-G6, which is a PA6-GF30, this becomes more complex. The glass fibers create different shrinkage rates depending on their orientation. This requires careful consideration during the tooling design phase to achieve precision.

Understanding Shrinkage Rates

The orientation of the glass fibers during injection directly impacts the part’s final dimensions. This effect, known as anisotropic shrinkage, is predictable. We have seen that designers must account for this difference to avoid dimensional errors in the final product.

| Direction | Typical Shrinkage Rate |

|---|---|

| Flow Direction | 0.2% – 0.5% |

| Cross-Flow Direction | 0.7% – 1.2% |

Why This Matters

Ignoring these different rates leads to warped or out-of-spec parts. Proper tooling compensation is not optional; it is a fundamental requirement for success. Getting this right from the start saves enormous time and resources on mold adjustments later.

The Impact of Glass Fiber Orientation

The primary factor driving anisotropic shrinkage in Akulon K224-G6 is the alignment of its 30% glass fiber content. During injection, these fibers tend to align with the direction of the polymer melt flow. This alignment significantly restricts shrinkage in the flow direction.

However, perpendicular to the flow, there is less fiber reinforcement. This allows the material to shrink more freely, resulting in a higher shrinkage rate. This discrepancy in shrinkage is a critical aspect of PA6-GF30 mold shrinkage that designers must manage.

Effective Tooling Compensation

Simply applying a uniform shrinkage value is a common mistake. Successful tooling compensation requires a deeper understanding of the part’s geometry and the material’s Rheology4. We advise clients to analyze the predicted melt flow to anticipate fiber orientation accurately.

| Strategy | Application |

|---|---|

| Differential Scaling | Apply different shrinkage factors to the mold core and cavity based on flow direction. |

| Gate Location Optimization | Position gates to control the fill pattern and fiber alignment for critical dimensions. |

| Warpage Simulation | Use software to predict and counteract part deformation before cutting steel. |

At MTM, we ensure our clients get the exact specified material, like Akulon K224-G6, for their trials. This consistency is vital because even minor material variations can alter flow behavior and disrupt carefully planned tooling compensation strategies.

Mastering Akulon K224-G6 dimensional stability requires a proactive approach to its anisotropic shrinkage. Effective tooling compensation, based on a clear understanding of glass fiber orientation and melt flow, is crucial for producing precise and reliable components without costly mold modifications.

Moisture Management: Best Practices for Drying Akulon K224-G6

Akulon K224-G6, a PA6-GF30, is highly sensitive to moisture. Proper drying isn’t just a suggestion; it’s a critical step for achieving optimal mechanical properties and a flawless surface finish. Ignoring this can lead to serious defects during molding.

Initial Drying Parameters

Before processing, reducing the moisture content is essential. We recommend using a dehumidifying dryer for consistent results. The right settings ensure that the material is ready for molding without being over-dried, which can also cause issues.

Recommended Settings

Here are the baseline drying parameters we use with our clients for Akulon K224-G6.

| Parameter | Recommended Value |

|---|---|

| Drying Temperature | 80°C (176°F) |

| Drying Time | 2 – 4 hours |

| Dew Point | -20°C (-4°F) or lower |

| Final Moisture | < 0.2% |

The Science Behind Drying

Simply heating the material isn’t enough. The goal is to prevent a chemical reaction called Hydrolysis5 during processing. At high temperatures in the molding machine, any residual water will break down the polymer chains, severely weakening the final part.

Why Dew Point Matters

A low dew point is crucial. It ensures the air used for drying is extremely dry, allowing it to effectively pull moisture from the pellets. Using hot, humid air is ineffective and can even add moisture back into the material, defeating the purpose of the drying process.

Consequences of Improper Drying

Based on our tests, we’ve seen a clear correlation between moisture content and part quality. Even a slight deviation can result in visible or structural defects. Having pre-stocked, properly handled material from a local hub like MTM eliminates transit-related moisture absorption.

| Drying Condition | Expected Outcome |

|---|---|

| Correct Drying | Strong parts, good surface finish |

| Insufficient Drying | Splay marks, brittleness, reduced strength |

| Over-Drying | Discoloration, poor flow characteristics |

Properly drying Akulon K224-G6 is non-negotiable for part quality. Adhering to specific temperature, time, and dew point settings prevents defects and ensures optimal performance, safeguarding your project’s integrity and timeline.

Mold Temperature Control: Influencing Surface Finish and Crystallinity

Mold temperature is a critical variable in injection molding that directly impacts the final part’s quality. It influences both the aesthetic appearance and the internal structure of the polymer. Proper control is essential for achieving the desired results, especially with engineered materials.

Surface Finish and Appearance

For materials like glass-filled polyamides, such as PA6-GF30, mold temperature is key to preventing defects. A common issue is "floating fiber," where glass fibers are visible on the part surface, creating a poor finish. A higher mold temperature helps avoid this.

Internal Crystalline Structure

The temperature also governs the crystallization rate6. A hotter mold allows polymer chains more time to organize into a stable crystalline structure, which enhances the material’s mechanical properties.

| Parameter | Low Mold Temperature | High Mold Temperature |

|---|---|---|

| Surface Finish | Risk of floating fiber | Smooth, resin-rich surface |

| Crystallinity | Lower, less developed | Higher, more optimal |

| Part Performance | Potentially weaker | Enhanced mechanical strength |

Controlling mold temperature involves a crucial trade-off between production speed and part quality. Engineers must carefully balance these factors to meet project requirements. This becomes particularly important when working with specific grades like Akulon K224-G6.

The Trade-Off: Cycle Time vs. Quality

A lower mold temperature allows for faster cooling, which shortens the overall cycle time. This increases production efficiency. However, it can compromise both the surface finish and the mechanical integrity of the part by limiting proper crystallization.

Optimizing for Glass-Filled Nylons

For a material like Akulon K224-G6, a higher mold temperature is often recommended. It ensures the resin stays fluid longer, effectively encapsulating the glass fibers. This process is essential for achieving a smooth, high-quality surface finish and preventing structural weaknesses.

Finding the Balance

The ideal temperature depends on the specific material and part design. At MTM, we often help clients fine-tune their processes during mold trials. Having the material readily available in China allows for quick adjustments without delays from international shipping.

| Factor | Low Mold Temperature | High Mold Temperature |

|---|---|---|

| Cycle Time | Faster | Slower |

| Surface Finish (PA6-GF30) | Poor (Floating Fiber) | Excellent |

| Crystallinity | Lower | Higher |

| Dimensional Stability | Less stable | More stable |

Mold temperature is a balancing act. It directly controls surface finish and crystallinity. Optimizing it requires careful consideration of both part quality and production efficiency, especially for materials like glass-filled nylons such as Akulon K224-G6.

Injection Speed and Pressure Strategies for Reinforced Nylon

Balancing Filling Speed

Controlling the filling speed for reinforced nylon is a delicate balance. Too fast, and the glass fibers can align improperly, leading to burns or flash. With a material like Akulon K224-G6, a moderate to fast injection speed is often the starting point. This ensures the cavity is filled before the material freezes off.

Effects of Speed Variation

Your filling speed for Akulon K224-G6 directly impacts part quality. We’ve seen that adjusting the speed profile in stages—slowing down near the end of fill—prevents many common defects.

| Speed Setting | Potential Outcome |

|---|---|

| Too High | Flashing, Gas Traps, Material Degradation |

| Too Low | Short Shots, Weld Lines, Poor Surface Finish |

The Molding Process Window

Finding the ideal molding process window is crucial. It’s the range of parameters that produces acceptable parts. For glass-filled materials, this window can be narrow. The glass fibers increase viscosity and create friction, generating more heat during injection.

Holding Pressure and Sink Marks

After the filling phase, holding pressure is applied to compensate for material shrinkage. In thick sections, inadequate holding pressure is a primary cause of sink marks. The key is to maintain enough pressure until the gate freezes, locking the material in place. Glass-filled nylons require higher holding pressures than unfilled grades.

Injection Pressure Settings

Your injection pressure settings must be high enough to overcome the flow resistance from the glass fibers. However, excessive pressure can cause flash or even damage the mold. A multi-stage pressure profile often works best. The material’s Shear Thinning7 behavior means its viscosity drops under higher injection speeds, affecting pressure requirements.

| Pressure Stage | Objective | Common Issue if Incorrect |

|---|---|---|

| Filling | Fill the cavity quickly and completely | Short shots or flash |

| Packing | Compensate for initial shrinkage | Voids or sink marks |

| Holding | Finalize part dimensions until gate freeze | Sink marks or overpacking |

At MTM, we ensure the material consistency of products like Akulon K224-G6, which helps you establish a reliable and repeatable molding process window for your trials.

Optimizing injection speed and holding pressure is essential for reinforced nylon. A stable molding process window, tailored to the material’s flow behavior, prevents common defects like flash and sink marks, ensuring consistent part quality during mold trials.

The Logistics Bottleneck: Challenges of Sourcing K224-G6 for China Trials

Sourcing specific resin grades like Akulon K224-G6 for mold trials in China introduces major logistical hurdles. The primary issue is the delay caused by international shipping and customs clearance. Relying on imports creates a significant bottleneck that can derail tight project schedules.

Import vs. Local Sourcing

The contrast is stark. Importing materials means navigating a complex, multi-stage process. Local sourcing, on the other hand, simplifies this down to a single domestic shipment. This directly impacts the speed and efficiency of your mold trial logistics.

Timeline Comparison

Here’s a typical breakdown of the time difference, based on our experience with many projects.

| Process Stage | Importing from Overseas | Sourcing Locally (MTM) |

|---|---|---|

| Order Processing | 2-3 Days | < 1 Day |

| International Transit | 2-4 Weeks | N/A |

| Customs Clearance | 1-2 Weeks | N/A |

| Domestic Delivery | 2-5 Days | 1-3 Days |

| Total Lead Time | 4-7 Weeks | 2-4 Days |

This table clearly shows how material import delays can add over a month to your schedule.

The core problem with sourcing resin in China via international shipment is unpredictability. While the shipping itself takes weeks, the real wildcard is customs. A single documentation error or a random inspection can hold up your materials, like Akulon K224-G6, for an unknown period.

Deconstructing Import Delays

Unexpected costs are another factor. Import duties, taxes, and brokerage fees can add a significant percentage to the material cost. These are often difficult to budget for accurately, creating financial uncertainty for the project manager.

Key Logistical Hurdles

The process involves far more than just shipping. Each step presents a potential failure point that can cascade, causing even longer delays. Understanding these risks is crucial for anyone managing projects in China.

| Hurdle | Impact on Mold Trial |

|---|---|

| Documentation Errors | Shipment held indefinitely by customs |

| Shipping Damage | Material unusable, requiring re-order |

| Customs Inspections | Unpredictable delays of days or weeks |

| Freight Forwarder Issues | Lost shipments or poor communication |

This is where a local partner becomes essential. At MTM, we eliminate these variables entirely. By pre-stocking critical materials like Akulon K224-G6, we turn a month-long international headache into a simple domestic delivery. The discussion often involves complex trade rules like Incoterms8, which can be confusing for teams focused on engineering, not logistics. Our role is to handle that complexity for you.

Importing specialized resins like Akulon K224-G6 for trials in China creates significant delays and risks. Sourcing locally bypasses customs, long transit times, and documentation hurdles, protecting your project schedule and budget from unpredictable logistics bottlenecks.

Ensuring Authenticity: Why Local Authorized Stock Matters

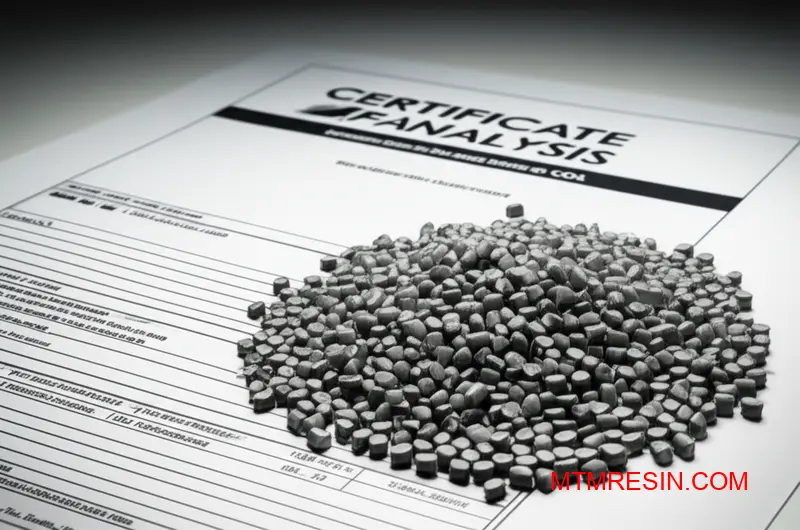

Sourcing materials locally in China can be risky. The market has counterfeit or "off-spec" products that look genuine but fail under stress. This is a major problem for precise materials like Akulon K224-G6, where performance is critical for mold validation.

The Real Cost of Fakes

Using a non-authentic material can lead to failed trials. This wastes time and money. It also damages your reputation if the final product does not meet specifications. Authenticity is not just a preference; it is a necessity for successful projects.

Why Verification Matters

| Feature | Authorized Stock | Unauthorized Source |

|---|---|---|

| Authenticity | Guaranteed | High Risk of Fakes |

| Performance | Meets Specs | Unpredictable |

| Documentation | Full Traceability | Missing or Forged |

| Project Impact | Smooth Trials | Delays, Rework |

The Power of Traceability

True traceability means you can follow the material’s journey. It starts from the original manufacturer to our warehouse in China. This is crucial for authentic DSM material China. Each batch should have a unique identifier that links back to its production data.

Decoding the Certificate of Analysis (COA)

A Certificate of Analysis (COA) is more than just a piece of paper. It is a formal resin material certification. This document provides specific test results for a material batch. It confirms properties like tensile strength and that it is heavy metal compliant.

The Assurance of a Valid COA

A reliable COA is your proof of quality. It provides the data you need to proceed with confidence. Without it, you are essentially guessing. We ensure every material, including Akulon K224-G6, comes with a valid COA. This process relies on a clear Chain of Custody9.

Using local authorized stock is the only way to guarantee material authenticity. It mitigates counterfeit risks, ensures proper documentation like a COA is available, and keeps your mold trial project on schedule without unexpected failures.

Case Study Context: Automotive Connector Applications

A frequent application I encounter for Akulon K224-G6 is in automotive engine control unit (ECU) connectors. These components demand exceptional reliability under harsh conditions. The material must provide structural integrity while resisting chemical exposure from fluids like oil and coolant.

Key Performance Requirements

For an ECU connector, the primary needs are stiffness and chemical stability. The part must maintain its shape and locking features without fail. Any degradation could lead to connection failure, a critical issue in automotive systems.

Material Suitability

Akulon K224-G6 is an ideal fit. Its 30% glass fiber reinforcement provides the necessary rigidity. Based on our tests, its polyamide 66 base offers excellent resistance to common automotive chemicals.

| Property | Requirement | Akulon K224-G6 Performance |

|---|---|---|

| Stiffness | High, to prevent deformation | Excellent (High Tensile Modulus) |

| Chemical Resistance | Resistant to oil, grease, fuel | Very Good |

| Temperature Stability | Stable up to 120°C | Good |

| Dimensional Stability | Low warpage and shrinkage | Consistent |

In automotive connector material selection, engineers often face a tough balance. They need high performance without driving up costs unnecessarily. This is where a deep understanding of engineering plastic applications becomes critical. A standard polyamide might work in a passenger cabin but will likely fail under the hood.

Challenges in Harsh Environments

The engine bay is a brutal environment. It combines high temperatures, constant vibration, and exposure to aggressive fluids. These factors accelerate material aging and can compromise connector integrity. The choice of material directly impacts long-term reliability. A poor choice leads to costly recalls and warranty claims.

The Role of Glass Fiber

The glass fibers in Akulon K224-G6 are key. They significantly enhance mechanical properties, especially stiffness and Creep resistance10. However, this reinforcement also introduces challenges in automotive injection molding, such as managing warpage and ensuring proper mold fill.

| Challenge | Mitigation Strategy |

|---|---|

| Warpage | Optimized gate location and cooling |

| Abrasive Wear | Use of hardened tool steel for molds |

| Anisotropic Shrinkage | Careful part and mold design |

This is why working with a material supplier like MTM is beneficial. We help clients anticipate these issues during mold trials, ensuring the material performs as expected.

This case study demonstrates how Akulon K224-G6 meets stringent automotive connector requirements for stiffness and chemical resistance. Proper engineering plastic application and addressing molding challenges are crucial for ensuring long-term part reliability in demanding environments.

Secure Your Akulon K224-G6 Mold Trials with MTM

Ready to fast-track your Akulon K224-G6 (PA6-GF30) mold trials? Contact MTM for authentic, pre-stocked resin—no international shipping delays, no off-spec risks. Get instant availability, certified quality, and expert support for your engineering projects in China. Send your inquiry today and optimize your workflow!

-

Understanding this helps manage part dimensions and performance in humid environments. ↩

-

Understanding this concept is key to predicting part strength based on mold flow and design. ↩

-

Explore this concept to better understand how polymer structure affects thermal performance and material selection. ↩

-

Explore rheology to better predict material flow, fiber orientation, and final part integrity. ↩

-

Understanding this reaction helps predict and prevent material degradation in polymers like Nylon 6. ↩

-

Understanding the crystallization rate helps in predicting a part’s final mechanical properties and performance under stress. ↩

-

Understanding this fluid property helps optimize injection speeds for better part quality and reduced cycle times. ↩

-

Understanding these trade terms clarifies shipping responsibilities and helps avoid unexpected costs. ↩

-

Learn how this logistical concept guarantees your material’s integrity from the source to your facility. ↩

-

Understanding this concept helps predict long-term part deformation under stress. ↩