Are you facing delays in your China mold trials because Daplen EE188HP isn’t available locally? Your automotive project timelines suffer when you’re forced to wait weeks for material shipments from overseas, while your mold sits idle and costs accumulate.

Daplen EE188HP is a high-impact thermoplastic polyolefin (TPO) specifically engineered for automotive exterior components, offering excellent impact resistance, paintability, and dimensional stability for bumper fascias and rocker panels.

I’ve worked with engineering teams who’ve lost weeks waiting for this specific grade to arrive in China. The material’s unique balance of stiffness and impact performance makes it irreplaceable for certain applications, but sourcing delays can derail your entire development schedule.

Technical Specifications: Unpacking Daplen EE188HP Physical Physicals

When engineers select materials for automotive exteriors, they look for a precise balance of properties. Daplen EE188HP is a Thermoplastic Polyolefin (TPO) frequently specified for bumpers and trim. Its success comes down to a few key data points on its technical sheet.

Core Material Attributes

The material’s physicals are not just numbers; they define its performance. Understanding them is crucial before any mold trial begins. At MTM, we ensure our clients receive materials matching these exact specifications for their projects in China.

Density and Flow Characteristics

The specific gravity and melt flow rate are fundamental. They dictate both the final part weight and the ease of processing during injection molding, which is especially important for large, complex parts like bumpers.

| Property | Value (Typical) | Unit |

|---|---|---|

| Density | 0.90 | g/cm³ |

| Melt Flow Rate (230°C/2.16 kg) | 12 | g/10 min |

The true value of Daplen EE188HP lies in its engineered balance between stiffness and toughness. Many materials are stiff but brittle, or tough but too flexible. This grade, however, provides the rigidity needed for a bumper to hold its shape while offering excellent impact resistance.

The Stiffness-to-Impact Ratio

For an automotive bumper, this ratio is non-negotiable. The part must resist minor bumps without permanent deformation but also absorb significant energy during a collision to protect passengers. The material’s formulation is tailored to meet these conflicting demands effectively.

Processing Window Considerations

A material’s processability is just as important as its final properties. The Melt Flow Rate (MFR)1 of 12 g/10 min is a sweet spot. It allows the polymer to fill large, intricate mold cavities completely without requiring excessive injection pressures, which could compromise part quality. Our clients rely on us to provide this consistent Daplen EE188HP grade, ensuring their mold trials accurately reflect production conditions.

| Performance Metric | Value (Typical) | Test Method |

|---|---|---|

| Flexural Modulus | 1200 | MPa |

| Izod Impact Strength, Notched (23°C) | 50 | kJ/m² |

In essence, Daplen EE188HP is specified for its reliable combination of processability, structural integrity, and high impact resistance. This balance makes it a predictable and high-performing choice for critical automotive exterior components, ensuring both safety and aesthetics are met.

Key Application Areas: Why Automotive Engineers Specify EE188HP

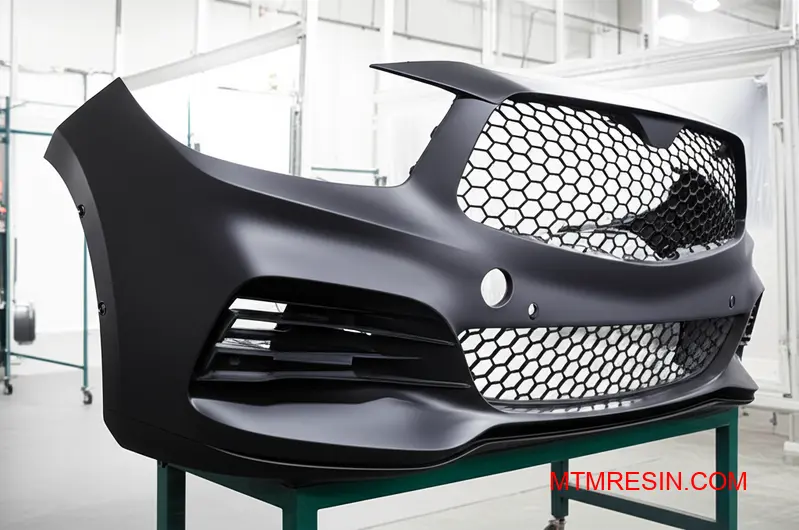

Daplen EE188HP is a go-to choice for automotive exterior components. Its properties are specifically engineered to meet the harsh demands of the road. Engineers frequently specify this material for parts that require both durability and a high-quality finish, a combination not easily achieved.

Primary Exterior Applications

The material is predominantly used for parts that face direct exposure to environmental and physical stress. Its formulation as an impact modified polypropylene balances stiffness with flexibility, making it a reliable automotive exterior resin.

Key Component Examples

- Bumper Fascias

- Rocker Panels

- Body Side Moldings

Here’s a quick breakdown of why it’s chosen for these parts:

| Component | Critical Requirement | Why EE188HP Excels |

|---|---|---|

| Bumpers | High Impact Strength | Absorbs energy from low-speed collisions effectively. |

| Rocker Panels | Paint Adhesion | Ensures a Class-A finish that lasts. |

The value of Daplen EE188HP becomes clear when we look at the entire manufacturing process. It’s not just about passing a lab test; it’s about performance from molding to the final vehicle assembly and beyond. This is why it’s a preferred bumper fascia material.

Beyond the Datasheet: Real-World Performance

For bumper fascias, the material must withstand minor impacts without cracking. The unique copolymer structure of Daplen EE188HP provides excellent low-temperature ductility. This ensures protection even in cold climates, a critical factor for global automotive platforms we encounter.

The Challenge of Paintability

Achieving a flawless paint finish on polypropylene can be difficult. However, its formulation is designed for superior paint adhesion. This reduces defect rates in the paint shop, saving time and cost. The material’s surface energy is optimized for modern automotive paint systems.

The standard for measuring this durability is often the Izod impact strength2 test. This data gives engineers confidence. At MTM, we supply Daplen EE188HP for mold trials because clients need to validate both fit and finish early on.

| Feature | Engineering Benefit | Production Impact |

|---|---|---|

| Low-Temp Ductility | Prevents cracking in cold weather | Reduces warranty claims |

| High Melt Flow | Good moldability for complex parts | Faster cycle times |

| Paint Adhesion | Flawless, durable finish | Lower paint shop rejection rates |

Daplen EE188HP is specified for automotive exteriors because its balance of impact strength and superior paintability solves key engineering and production challenges. It delivers the durability and aesthetic quality required for modern vehicles, making it a top bumper fascia material.

Injection Molding Parameters: Processing Window for Daplen EE188HP

Dialing in the processing window for Daplen EE188HP is non-negotiable for a successful mold trial. Small miscalculations in your machine settings can introduce defects that compromise part integrity and appearance. This guide establishes a reliable baseline for your initial setup.

Core Temperature Settings

A stable temperature profile is the foundation. For Daplen EE188HP, it’s crucial to establish a gradient that ensures uniform melting without degrading the polymer. This prevents issues like black specks or inconsistent flow during injection.

Recommended Temperature Zones

The following table outlines our recommended starting points based on tests we’ve conducted with clients. Adjustments may be needed based on your specific mold and machine.

| Parameter | Recommended Value | Unit |

|---|---|---|

| Rear Zone | 180 – 200 | °C |

| Middle Zone | 200 – 220 | °C |

| Front Zone | 220 – 240 | °C |

| Nozzle | 230 – 250 | °C |

Pressure and Speed Optimization

Proper injection pressure ensures the cavity is filled completely without creating flash. I recommend starting with a moderate pressure and observing the part for signs of under-filling or over-packing. This approach helps you find the sweet spot for Daplen EE188HP quickly.

Fine-Tuning Your Process

Screw speed optimization is equally important for maintaining material integrity. Too high a speed can generate excessive shear heat, degrading the material. A low back pressure is generally preferred, just enough to ensure a homogeneous melt and stable shot size.

This material grade exhibits shear thinning3 behavior, meaning its viscosity drops under higher injection speeds. This property is advantageous for filling complex geometries or thin-walled sections. Mastering injection speed is therefore key to leveraging the full potential of Daplen EE188HP.

| Setting | Guideline | Purpose |

|---|---|---|

| Injection Pressure | 600 – 1000 bar | Fills the mold cavity completely |

| Holding Pressure | 40-60% of Injection | Prevents sink marks and voids |

| Back Pressure | 50 – 100 bar | Ensures consistent melt density |

| Screw Speed | 40 – 70 rpm | Controls melt uniformity and heat |

At MTM, we stock materials like Daplen EE188HP in China, so our clients can validate these parameters without delays from international shipping.

Mastering the Daplen EE188HP molding guide requires precise control over its processing window. Using these temperature and pressure settings as a starting point is the most effective way to achieve high-quality, defect-free parts during your crucial mold trials.

Understanding Shrinkage Rates and Dimensional Stability

For mold designers, shrinkage is not just a number; it is a critical variable that dictates tooling accuracy. Understanding the expected Daplen EE188HP shrinkage rate is fundamental to creating a successful mold that produces dimensionally stable parts from the very first trial.

Expected Shrinkage Range

Based on our data, Daplen EE188HP typically exhibits a shrinkage rate between 1.2% and 1.8%. This range is influenced by factors like wall thickness, gate location, and processing parameters. Accurate prediction is key to setting correct mold design tolerances.

Impact on Tooling

| Direction | Typical Shrinkage | Implication for Mold Design |

|---|---|---|

| Flow Direction | Lower End of Range | Cavity must account for less shrinkage along the polymer flow path. |

| Across-Flow | Higher End of Range | Cavity requires greater compensation for shrinkage perpendicular to flow. |

Shrinkage is rarely uniform across a part. The direction of polymer flow during injection molding significantly impacts the final dimensions. This behavior, known as anisotropic4 shrinkage, is a primary concern for achieving tight dimensional stability and is a core part of any discussion around mold design tolerances.

The Role of Flow Direction

During injection, long polymer chains in the molten plastic align themselves in the direction of flow. This orientation means that shrinkage along the flow path is different from shrinkage perpendicular to it. This across-flow shrinkage is usually higher because the polymer chains contract more as they cool in that direction.

Managing Dimensional Accuracy

We often advise clients that ignoring this effect can lead to warped or out-of-spec parts. For a material like Daplen EE188HP, precise tooling requires compensating for this differential. A skilled toolmaker will adjust cavity dimensions based on flow simulation results to ensure the final product meets all specifications.

| Processing Parameter | Effect on Shrinkage |

|---|---|

| Injection Pressure | Higher pressure reduces shrinkage. |

| Melt Temperature | Higher temperature can increase shrinkage. |

| Packing Time | Longer packing reduces shrinkage. |

Understanding the Daplen EE188HP shrinkage rate and its anisotropic nature is crucial for mold design. Factoring these variables into tooling tolerances from the start prevents costly rework and ensures final part dimensional stability, which is our goal at MTM.

Managing Viscosity and Flow Characteristics in Complex Molds

Filling complex molds, especially for large automotive parts, presents a significant challenge. The key is managing material viscosity to ensure complete filling without defects. An improper flow can lead to stress marks, weak points, or incomplete parts, causing costly delays during mold trials.

The Role of Material Selection

Choosing the right material is the first step. A polymer like Daplen EE188HP is designed for such applications. Its flow characteristics are optimized for intricate geometries, making it a reliable choice for demanding projects where part quality is critical.

Common Molding Challenges

| Challenge | Consequence |

|---|---|

| High Injection Pressure | Stress Marks / Warping |

| Slow Fill Speed | Short Shots / Flow Lines |

| Poor Flow Length | Incomplete Part Filling |

| Inconsistent Viscosity | Unpredictable Quality |

This is why we often recommend specific grades. At MTM, we stock materials like Daplen EE188HP in China, so our clients can immediately address these challenges without waiting for overseas shipments.

Analyzing Material Flow Behavior

A deeper understanding of a material’s rheology5 is essential for success. For Daplen EE188HP, its viscosity curve shows a predictable response to injection speed and pressure. This behavior is crucial for achieving consistent results in thin-wall injection molding applications.

Mold Filling Analysis

Before trials, we often review mold filling analysis data with clients. This simulation helps predict how Daplen EE188HP will behave. We focus on ensuring the melt front advances evenly, which minimizes the internal stress that causes visible defects on the final part’s surface.

Optimizing for Thin Walls

Large, thin-walled parts require a material with an excellent flow length ratio. Based on our tests, Daplen EE188HP maintains low viscosity under high shear rates. This allows it to travel long distances within the mold cavity without premature freezing, ensuring a fully formed part.

| Parameter | Impact on Flow |

|---|---|

| Melt Temperature | Higher temp lowers viscosity |

| Injection Speed | Higher speed reduces viscosity |

| Wall Thickness | Thinner walls increase resistance |

| Gate Location | Affects flow path and pressure |

By controlling these factors, we can leverage the material’s properties to produce high-quality components. Having this material locally available means adjustments can be made quickly, accelerating the entire mold validation process for our partners.

Effectively managing viscosity is crucial for complex molds. Materials like Daplen EE188HP, with their optimized flow characteristics, enable defect-free production of large, thin-walled parts, ensuring project success and reducing costly trial-and-error cycles.

Surface Finish and Paint Adhesion Capabilities

Achieving a high-quality surface finish is critical for exterior automotive parts. Daplen EE188HP is designed for these applications, but the final result depends heavily on processing. A Class A surface is the goal, requiring precise control over molding parameters and tool design.

Factors Influencing Surface Quality

The material’s flow characteristics and the mold’s surface texture are primary factors. Even minor variations in temperature or injection speed can lead to visible defects. Consistent processing is key to avoiding these issues during mold trials.

| Factor | Impact on Surface |

|---|---|

| Melt Temperature | Affects material flow and replication of mold texture. |

| Injection Speed | Influences the presence of flow lines or jetting. |

| Mold Temperature | Critical for achieving a uniform, glossy finish. |

| Packing Pressure | Helps minimize sink marks over ribs or bosses. |

The excellent appearance of a molded part is only half the story. For exterior components, paint adhesion is crucial for both aesthetics and long-term durability. Daplen EE188HP, being a polypropylene compound, requires specific preparation before painting. This is a common challenge with polyolefin materials.

Surface Preparation for Painting

Materials like this have a low surface energy6, which naturally repels liquids like paint. To ensure strong paint adhesion, the surface must be treated. Common methods include flame treatment, plasma treatment, or applying a specialized adhesion promoter (primer) before the base coat.

Preventing Common Aesthetic Defects

Aesthetic defects often trace back to the molding process itself. When clients run mold trials, we often discuss how to troubleshoot these issues. Having the correct material grade from MTM ensures that you are not chasing problems caused by an improper substitute.

| Defect | Potential Cause |

|---|---|

| Sink Marks | Insufficient packing pressure or thick wall sections. |

| Flow Lines | Low melt temperature or inconsistent injection speed. |

| Weld Lines | Poor gate location or sub-optimal flow front merging. |

| Gloss Variation | Inconsistent mold temperature or moisture in material. |

Proper paint adhesion testing, such as the cross-hatch test, is essential to validate the entire process. This ensures the final product meets stringent OEM standards.

Achieving a Class A surface finish and reliable paint adhesion on Daplen EE188HP requires a holistic approach. It involves precise molding control, appropriate surface preparation, and rigorous testing. Success depends on managing both the material properties and the manufacturing process effectively.

Troubleshooting Common Defects: Tiger Stripes and Flow Marks

Tiger stripes and flow marks are common surface defects in injection molding. They often appear as wavy or dull bands on the part’s surface. These issues are particularly prevalent when working with high-impact polyolefins.

The Challenge with High-Flow Materials

Materials like Daplen EE188HP have a specific melt flow behavior that can lead to these defects. The inconsistent flow front speed as the plastic fills the mold cavity is usually the root cause. This creates visible variations in the surface finish, impacting the part’s final appearance.

Identifying the Root Cause

These marks are not just cosmetic; they can indicate underlying process inconsistencies. Correctly diagnosing the problem during mold trials is crucial. It saves time and prevents issues in mass production later.

Solving these surface defects requires a methodical approach to process parameters. When we supply Daplen EE188HP for trials, we often start by looking at gate velocity and temperature settings, as they have the most direct impact on melt flow behavior.

Adjusting Gate Velocity and Temperature

The speed at which molten plastic enters the cavity is critical. A non-uniform velocity can cause the melt front to hesitate and accelerate, creating stripes. Adjusting the injection speed profile helps maintain a consistent flow front, which is key to eliminating these marks. This can also prevent issues like Melt fracture7 at high shear rates.

Melt and mold temperatures also play a significant role. Increasing them can lower the material’s viscosity, promoting smoother flow. However, finding the right balance is essential to avoid other problems like material degradation or longer cycle times.

Troubleshooting Parameter Adjustments

Here is a simple guide we use to tackle these issues during trials.

| Defect | Potential Cause | Recommended Action |

|---|---|---|

| Tiger Stripes | Unstable melt front velocity | Increase injection speed; optimize speed profile |

| Flow Marks | Low melt or mold temperature | Gradually increase melt and mold temperature |

| Dull Spots | Poor melt homogenization | Increase back pressure; raise barrel temperatures |

At MTM, we help clients fine-tune these parameters, ensuring the material performs as expected. Getting the process right early saves significant costs down the line.

Fixing tiger stripes and flow marks on parts molded with Daplen EE188HP comes down to precise control over gate velocity and melt temperature. A systematic approach during mold trials ensures a high-quality surface finish and prevents costly production delays.

Optimizing Cooling Times for Cycle Efficiency

The cooling phase often dictates the overall cycle time in injection molding. For a material like Daplen EE188HP, managing this stage is crucial. It’s a balance between speed and quality. Rushing the cooling can lead to significant warpage, while being too cautious extends the cycle unnecessarily.

Mold Temperature and Part Quality

Proper mold temperature control is the first step. A lower temperature might seem to shorten cooling time, but it can induce stress and defects. Finding the optimal window requires careful consideration of the part’s geometry and material specifications. This balance is key to warpage prevention.

Cooling Time Factors

Here is a simplified look at the trade-offs involved in mold temperature control.

| Mold Temperature | Cooling Time | Warpage Risk | Surface Finish |

|---|---|---|---|

| Low | Shorter | High | Can be poor |

| Optimal | Moderate | Low | Good |

| High | Longer | Very Low | Excellent |

To truly master cycle time reduction, we must look beyond just temperature. The design of the mold’s cooling channels plays an indispensable role. It’s not just about getting water through the mold; it’s about strategic heat extraction where it is most needed.

Cooling Channel Design Principles

Effective cooling channel design focuses on uniformity. Channels should follow the contour of the part as closely as possible, ensuring even heat removal. This prevents one area from cooling much faster than another, which is a primary cause of warpage, especially in complex geometries using materials like Daplen EE188HP.

Optimizing Coolant Flow

The properties of the coolant itself also matter. After working on several projects with our clients, we’ve found that flow rate is just as important as temperature. A turbulent flow is more effective at heat transfer than a laminar one. This ensures the mold surface temperature remains stable throughout the cycle. The part’s ability to withstand ejection forces is linked to its Heat Deflection Temperature8.

| Parameter | Impact on Cooling Efficiency | Recommendation |

|---|---|---|

| Channel Diameter | Affects coolant volume and flow rate | Match to part size; avoid overly restrictive paths |

| Channel Placement | Determines uniformity of heat extraction | Follow part geometry; use conformal cooling for complex shapes |

| Coolant Flow Rate | Influences heat transfer efficiency (turbulent vs. laminar) | Target a Reynolds number that ensures turbulent flow |

At MTM, we support our clients by providing consistent materials, which allows them to fine-tune these process parameters without material variability clouding the results.

Optimizing cooling requires a systematic approach. By carefully managing mold temperature, cooling channel design, and coolant flow, you can significantly reduce cycle times. This balance prevents warpage and ensures consistent part quality for materials like Daplen EE188HP, boosting overall production efficiency.

Ensuring Material Consistency: Lot-to-Lot Variation Risks

The fear of receiving counterfeit or off-spec material in China is a valid concern for many project managers. Using unverified resin for a mold trial can invalidate the entire process. The results simply won’t reflect what you can expect during mass production, leading to costly errors later.

The Problem with Unverified Resins

An unverified batch of a material like Daplen EE188HP might look correct, but its properties can be vastly different. This discrepancy introduces variables that undermine the trial’s purpose. You end up testing the mold with a material you will never actually use in production.

Securing a Genuine Daplen Supply

Ensuring resin consistency starts with a trusted source. Material certification is non-negotiable. We always perform COA verification to confirm that every batch meets the exact specifications required by our clients. This is how we guarantee a genuine Daplen supply for critical trials.

| Verification Step | Verified Material | Unverified Material |

|---|---|---|

| Source | Authorized Distributor | Unknown or Grey Market |

| COA | Matches Batch Number | Missing or Forged |

| Performance | Predictable & Consistent | Unpredictable & Risky |

| Trial Validity | High | Low / None |

Using pre-stocked, authorized material is the only way to ensure your trial results are valid. When a client requests Daplen EE188HP, they receive genuine material from a controlled supply chain. This eliminates the guesswork and risk associated with local sourcing from unvetted suppliers. It protects the integrity of the mold trial.

The Role of COA Verification

A Certificate of Analysis (COA) is more than a piece of paper; it’s a guarantee. We meticulously cross-reference the COA with the material’s batch number and supplier records. This COA verification process confirms that the material’s properties—like melt flow and impact strength—are exactly as specified by the manufacturer.

From Source to Trial

Our process ensures complete material Traceability9 from the moment it leaves the manufacturer to its arrival at the mold trial facility. This unbroken chain of custody is crucial for quality control. It provides documented proof that the material is authentic and has been handled correctly, maintaining its specified properties. This level of diligence ensures resin consistency across every trial.

| Verification Stage | Action Taken | Outcome |

|---|---|---|

| Sourcing | Procure from authorized channels | Guaranteed genuine material |

| Receiving | Match batch numbers to COA | Confirmed material identity |

| Storage | Controlled environment | Preserved resin integrity |

| Dispatch | Documented lot information | Full transparency for client |

This systematic approach provides peace of mind. Your mold trial data becomes a reliable benchmark for mass production, because the material is exactly what it claims to be.

Using verified, pre-stocked materials like Daplen EE188HP eliminates risks from counterfeit resins. It ensures your mold trial data is accurate and directly applicable to mass production, safeguarding your project’s timeline and quality.

Comparison Guide: Daplen EE188HP vs. Similar TPO Grades

Choosing the right TPO grade is critical for automotive components. Daplen EE188HP is a popular choice, but how does it stack up against other common TPOs? The decision often comes down to the specific application and part geometry.

Initial Grade Comparison

Let’s look at a high-level overview. When clients in China need a material for a new mold trial, we often compare Daplen EE188HP with grades from other major suppliers. Each has its strengths, but performance varies in key areas.

Key Performance Indicators

A quick comparison shows distinct differences. Based on our internal testing data, Daplen EE188HP often shows a balanced profile, particularly in impact strength versus stiffness, which is crucial for parts like bumpers and door claddings.

| Property | Daplen EE188HP | Competitor A (High Flow) | Competitor B (High Impact) |

|---|---|---|---|

| MFR (230°C/2.16kg) | Medium | High | Low |

| Izod Impact (23°C) | High | Medium | Very High |

| Tensile Modulus | Medium-High | Medium | Low-Medium |

| Application Focus | General Purpose / Bumpers | Thin-Wall Parts | Energy Absorbers |

This balance makes Daplen EE188HP a versatile starting point for many projects.

When we dive deeper, the choice of Daplen EE188HP over a competitor often relates directly to the part’s design. A simple resin grade substitution isn’t always possible without considering the mold and geometry. My team at MTM frequently helps clients navigate this.

Performance in Specific Geometries

For parts with complex geometries, such as deep ribs or integrated clips, material flow and stiffness are paramount. Daplen EE188HP provides a good balance, but its advantages become clear in certain situations. It avoids the brittleness of some high-stiffness grades while offering better structural integrity than high-flow alternatives.

Thin-Walled Sections

In thin-walled components, a high-flow TPO might seem ideal. However, it can sometimes lead to reduced impact performance. Daplen EE188HP’s formulation provides sufficient flow without compromising the part’s durability, a critical factor we verify during mold trials.

Large, Structural Parts

For larger parts like fascia or instrument panel carriers, stiffness is key to prevent warping and ensure fit. This is where Flexural Modulus10 becomes a critical parameter. EE188HP’s profile provides the rigidity needed for dimensional stability over a wide temperature range.

| Part Geometry | Key Challenge | Why Daplen EE188HP Fits |

|---|---|---|

| Large Bumper Fascia | Warpage, Sag | Balanced stiffness and thermal stability |

| Door Cladding | Impact Resistance, Finish | Excellent low-temperature impact |

| Interior Trim w/ Clips | Brittleness, Sink Marks | Good flow with structural integrity |

Ultimately, selecting the right TPO requires matching the material’s datasheet to the part’s real-world demands.

Choosing between Daplen EE188HP and competitors depends heavily on part geometry and performance requirements. While other TPOs excel in specific areas like high flow or impact, EE188HP offers a balanced profile suitable for a wide range of challenging automotive applications.

The MTM Advantage: Immediate Availability for T1 Trials

The T1 trial is a critical milestone, but it often hits a wall: the specified material isn’t available locally. Waiting for resins like Daplen EE188HP to ship from overseas introduces delays and significant costs, jeopardizing the entire project timeline from the very start.

The Common Bottleneck

Project managers frequently face this challenge. The tool is ready, the team is assembled, but the trial cannot begin. This waiting period is not just idle time; it represents lost momentum and escalating costs that could have been easily avoided.

Our Solution: Pre-Stocked Inventory

At MTM, we eliminate this bottleneck. We maintain a ready stock of critical materials, including Daplen EE188HP, right here in China. This ensures you get the exact grade you need for your T1 trial without any international shipping delays.

| Sourcing Method | Lead Time | Cost Impact |

|---|---|---|

| Overseas Shipment | 4-8 Weeks | High (Freight + Tariffs) |

| MTM Local Stock | 1-3 Days | Low (Local Delivery) |

The core issue extends beyond simple logistics. When a material like Daplen EE188HP is missing, the entire validation process halts. This isn’t just about a delayed T1; it creates a cascade of problems that affect subsequent trial stages and final part approval.

Beyond T1: The Ripple Effect

A delay at the T1 stage means postponed T2 and T3 trials. This directly impacts your ability to provide samples to your end customer on time. Your team’s focus shifts from refining the tool to managing logistical headaches, which is an inefficient use of skilled engineering resources.

Building a Resilient Sourcing Strategy

Relying on a global supply chain for time-sensitive trials lacks the necessary flexibility. I advise clients to build a more resilient strategy. This involves having a local partner who understands material equivalency and can provide supply chain elasticity11 for urgent needs. That’s our role at MTM.

When you need to buy Daplen EE188HP in China, our local stock provides the solution. We offer instant resin delivery, providing fast mold trial support that keeps your project moving forward without interruption. MTM stock availability turns a potential weeks-long delay into a matter of days.

Material delays for T1 trials are a significant risk. By stocking materials like Daplen EE188HP in China, MTM provides instant resin delivery. This service offers fast mold trial support, eliminating bottlenecks and keeping your project on track from the beginning.

Secure Your Daplen EE188HP Trials With MTM Expertise

Ready for a flawless mold trial with Daplen EE188HP? Reach out now for a fast quote or material reservation with MTM—your China-based source for certified, immediate stock. Avoid delays or material mismatches—let our experts handle your TPO needs from start to finish!

-

Understand how this single value dictates processing windows and final part quality. ↩

-

Understanding this metric helps quantify material toughness, crucial for evaluating performance in real-world automotive impacts. ↩

-

Understanding this property helps optimize injection speed and pressure for better material flow and final part quality. ↩

-

Explore how this property affects material behavior and engineering design in various applications. ↩

-

Understanding rheology helps predict material behavior in the mold, optimizing injection parameters and preventing defects. ↩

-

Understanding this concept helps in selecting the right surface treatment for strong paint adhesion on plastics. ↩

-

Understanding this concept helps predict and prevent surface defects that can occur at high injection speeds. ↩

-

Understanding this property helps predict part stability during ejection, crucial for high-temperature applications. ↩

-

Understanding traceability helps build robust supply chains and ensure consistent product quality from raw material to final part. ↩

-

Understanding this value helps predict part deformation under stress, crucial for designing durable components. ↩

-

Learn how this concept directly affects your project’s ability to adapt to material shortages and sourcing challenges. ↩