LuranFinding the right ASA grade for your exterior components shouldn’t derail your project timeline. When overseas material shipments face delays or customs issues, your T0 trials get pushed back, and suddenly your entire development schedule is at risk.

Luran S 778T delivers the thermal stability and UV resistance needed for demanding outdoor applications, with its high heat ASA formulation providing superior weathering performance compared to standard ABS materials.

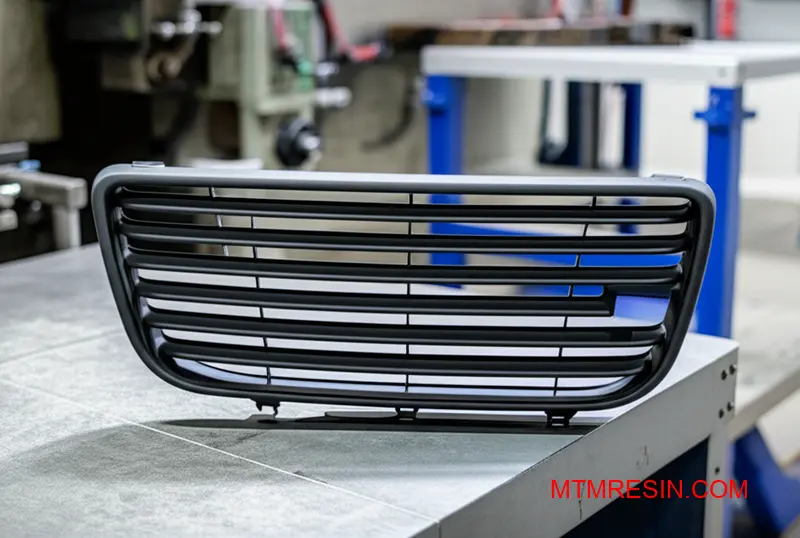

I’ve worked with engineering teams who needed this specific grade for automotive grilles and mirror housings. Getting the right material specification is just the first step – securing reliable supply for your mold trials makes the real difference in meeting project deadlines.

Why Specify Luran S 778T for High-Performance Exteriors?

Engineers often specify Luran S 778T when failure is not an option. This high-heat ASA (Acrylonitrile Styrene Acrylate) sets a benchmark for performance in demanding outdoor applications, from automotive trim to industrial housings, where durability is non-negotiable.

Core Advantages for Exterior Use

Its unique formulation provides superior resistance to environmental stressors. This ensures long-term aesthetic and structural integrity, which is critical for brand reputation and product lifespan. The material’s reliability is a key factor driving its specification in high-value components.

Key Performance Indicators

| Feature | Benefit |

|---|---|

| High Heat Deflection | Maintains shape under direct sun load |

| Excellent UV Stability | Resists color fade and surface chalking |

| High Impact Strength | Durable against physical stress and impact |

Beyond the Datasheet: Real-World Performance

A datasheet only tells part of the story. The real test is how a material performs over years of exposure. Standard materials might look good initially but can quickly degrade, leading to costly warranty claims and brand damage down the line.

Luran S 778T’s resilience comes from its robust acrylic ester rubber phase. This structure is inherently more stable against Photo-oxidation1 compared to other styrenics like ABS. This chemical stability is what prevents brittleness and surface cracking over time, preserving the part’s integrity.

Critical Application Considerations

I’ve worked with clients who switched to Luran S 778T after experiencing field failures with other materials. The issue often lies in combined thermal and UV stress, especially in dark-colored parts that absorb significant heat and radiation.

Material Comparison in Harsh Environments

| Material | UV Resistance | Heat Resistance | Long-Term Stability |

|---|---|---|---|

| Standard ABS | Poor | Moderate | Low |

| PC/ABS Alloy | Moderate | Good | Moderate |

| Luran S 778T | Excellent | High | Excellent |

This grade ensures that components like mirror housings or radiator grilles retain their gloss, color, and mechanical properties. At MTM, we stock Luran S 778T so your team can validate these properties during mold trials without costly shipping delays.

Specifying Luran S 778T is a strategic decision for high-performance exteriors. Its exceptional weathering resistance and high-heat stability ensure product longevity and protect brand value, making it a reliable choice for critical outdoor applications where durability is paramount.

Analyzing the Thermal Properties of Luran S 778T

When selecting a material like Luran S 778T, its thermal properties are often the deciding factor. This ASA copolymer is known for its excellent heat resistance, which is crucial for parts that will be exposed to elevated temperatures. We need to look beyond general statements and examine specific data points.

Key Thermal Indicators

Understanding a material’s performance under heat involves two primary metrics. These values tell us how a material behaves when subjected to thermal stress, which is vital for predicting its real-world durability and maintaining its shape.

Vicat and HDT Values

The Vicat softening temperature and Heat Deflection Temperature (HDT) are critical. They indicate the point at which the material begins to lose its rigidity. For Luran S 778T, these values are notably high.

| Property | Value (Approx.) | Test Method |

|---|---|---|

| Vicat Softening Temp. (B50) | 104 °C | ISO 306 |

| Heat Deflection Temp. (0.45 MPa) | 98 °C | ISO 75-2/B |

This data shows its capacity to maintain structural integrity under load at high temperatures.

The ‘High Heat’ designation for Luran S 778T isn’t just marketing; it’s backed by specific performance metrics. Let’s look at what these numbers mean in a practical sense, especially for demanding applications where thermal stability is a non-negotiable requirement.

Decoding High-Heat Performance

The two most important figures are the Vicat softening point and the Heat Deflection Temperature (HDT). Vicat testing determines the temperature at which a standard needle penetrates the material, signaling softening. HDT measures the temperature at which a sample deforms under a specific load.

Importance for Automotive Parts

Consider an exterior automotive part, like a grille or mirror housing, painted a dark color and sitting in direct sunlight. Surface temperatures can easily exceed 80-90°C. A material with a low HDT would warp or sag, leading to failure. Luran S 778T’s high HDT ensures dimensional stability under heat. This is a critical factor we help clients verify at MTM during mold trials for new components, preventing costly post-launch issues. This relates directly to the material’s Glass transition temperature2, which defines its transition from a rigid to a more pliable state.

Luran S 778T’s robust thermal properties ensure it maintains its shape and mechanical integrity in high-temperature environments. This makes it a reliable choice for automotive parts and other applications where heat exposure is a constant concern, guaranteeing long-term dimensional stability and performance.

UV Resistance and Weatherability: Beyond Standard ABS

When designing parts for outdoor use, standard ABS often falls short. Its susceptibility to UV radiation leads to rapid degradation, causing discoloration and brittleness. This is a common issue I see when clients try to use general-purpose grades for demanding applications.

The Weakness of Standard ABS

The primary issue with ABS is its butadiene rubber component. While it provides impact strength, it is highly vulnerable to UV light. This results in poor long-term weatherability.

Introducing a Superior Alternative: ASA

This is where ASA (Acrylonitrile Styrene Acrylate) materials, such as Luran S 778T, excel. They are engineered specifically for outdoor performance and color stability. They offer a reliable solution for durable parts.

Key Performance Differences

| Property | Standard ABS | Luran S 778T (ASA) |

|---|---|---|

| UV Resistance | Poor | Excellent |

| Color Fastness | Low | High |

| Impact Strength | Good | Excellent |

| Long-Term Durability | Fair | Excellent |

The fundamental difference between ASA and ABS lies in their chemical structure. This distinction is crucial for understanding weathering performance. Many project teams overlook this detail during material selection, leading to field failures later.

The Acrylate Rubber Advantage

Standard ABS incorporates a butadiene rubber phase. The double bonds in its structure are easily broken by UV radiation. This process degrades the polymer, causing the material to yellow and become brittle. This is a classic failure mode for ABS in outdoor settings.

In contrast, Luran S 778T is an ASA polymer. It uses a saturated acrylate rubber phase, which lacks the vulnerable double bonds found in butadiene. This inherent stability makes it exceptionally resistant to UV degradation and oxidation. The result is superior color fastness and mechanical property retention over time. The formation of chromophores3 is significantly reduced.

Performance in Weathering Tests

Our analysis of accelerated weathering data shows a stark contrast. This is critical for clients needing to validate parts quickly, and having Luran S 778T ready in our China warehouse helps them meet tight schedules.

| Performance Metric | Standard ABS | Luran S 778T (ASA) |

|---|---|---|

| Gloss Retention | Poor | Excellent |

| Color Shift (ΔE) | High | Very Low |

| Impact Retention | Low | High |

| Surface Cracking | Prone | Resistant |

For outdoor applications, the choice is clear. ASA materials like Luran S 778T offer superior UV resistance and color stability compared to standard ABS. This is due to the inherent chemical stability of its acrylate rubber phase, ensuring long-term performance and aesthetic appeal.

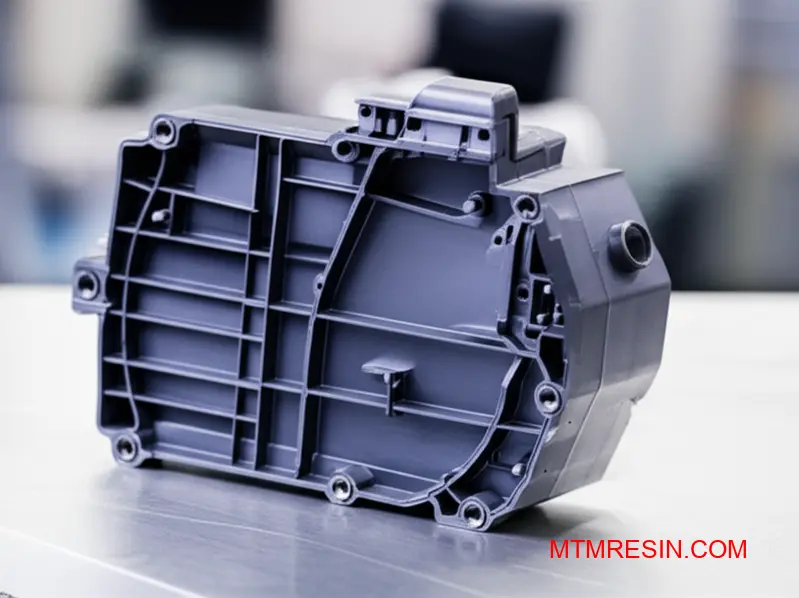

Key Mechanical Properties for Structural Integrity

Understanding a material’s datasheet is fundamental for ensuring structural integrity. Three key values provide a snapshot of performance: tensile modulus, impact strength, and elongation at break. These figures are not just numbers; they directly predict how a component will behave under real-world stress and strain.

What the Numbers Mean

For engineers, interpreting these properties correctly is the first step toward a successful design. It avoids costly revisions and ensures the final product meets its functional requirements from the start.

| Property | Represents | Critical For |

|---|---|---|

| Tensile Modulus | Stiffness, resistance to bending | Structural housings, load-bearing parts |

| Impact Strength | Toughness, ability to absorb shock | Drop-prone devices, snap-fits |

| Elongation at Break | Ductility, ability to stretch | Snap-fits, living hinges |

A material like Luran S 778T is often selected because its datasheet shows a good balance of these characteristics.

When I review a mechanical datasheet, I look beyond the individual values and consider how they interact. This analysis is crucial for predicting performance, especially for parts with complex geometries like snap-fits or load-bearing housings.

Interpreting Tensile Modulus

Tensile modulus is a measure of stiffness. For a structural housing, a high tensile modulus is essential. It ensures the part will not deform under its own weight or external loads, maintaining its intended shape and protecting internal components. A low modulus would result in a flimsy part.

Balancing Impact and Elongation

For features like snap-fits, a different balance is needed. High impact resistance, often measured by Charpy tests, ensures the clip won’t shatter during assembly. At the same time, sufficient elongation at break is vital. This property allows the material to flex enough to engage and disengage without permanent damage.

For example, when specifying a material like Luran S 778T for a project, we analyze its tensile strength alongside its impact properties. We also consider factors like flow direction during molding, which can influence Anisotropy4 and affect the final part’s strength. At MTM, we help teams avoid delays by providing such materials directly in China for immediate mold trials.

A balanced understanding of tensile modulus for stiffness, impact strength for durability, and elongation for flexibility is critical. These datasheet values are the foundation for designing robust and reliable parts, directly influencing material selection and preventing failures in the field.

Mold Temperature Control for Surface Aesthetics

Controlling mold temperature is crucial for achieving the desired surface aesthetics on plastic parts. For a material like Luran S 778T, this variable directly dictates the final appearance, from high gloss to a matte finish. It’s a delicate balance we manage in every project.

The Temperature-Gloss Relationship

A higher mold temperature allows the molten polymer to flow more easily and replicate the mold surface with greater fidelity. This results in a higher gloss. Conversely, a lower temperature causes the material to solidify faster, creating a less reflective, or matte, surface.

Balancing Aesthetics and Cycle Time

While a high temperature improves gloss, it also extends the cooling period, leading to longer cycle times. Finding the right balance is key for efficient production. This balance is a core part of optimizing any molding process.

| Parameter | High Mold Temperature | Low Mold Temperature |

|---|---|---|

| Surface Gloss | High | Low / Matte |

| Cycle Time | Longer | Shorter |

| Weld Lines | Less Visible | More Visible |

| Shrinkage | Higher | Lower |

Proper mold temperature control is more than just setting a number; it’s about understanding material behavior. For Luran S 778T, the temperature directly impacts how the polymer molecules arrange themselves as they cool, which defines the surface gloss and overall part quality.

Achieving a High-Gloss Finish

To get a mirror-like finish, we typically recommend a mold surface temperature between 60°C and 80°C. This keeps the material fluid longer, allowing it to perfectly copy the polished steel surface of the mold. It minimizes flow lines and enhances the visual appeal.

Textured Finishes and Cycle Time Optimization

For textured parts, a lower temperature (40°C to 60°C) is often better. It helps capture the fine details of the texture without creating unwanted gloss. This also contributes to cycle time optimization, a constant goal in manufacturing. The material’s Rheology5 is a key factor here; temperature changes its flow characteristics significantly.

| Finish Type | Recommended Temp (°C) | Key Outcome |

|---|---|---|

| High-Gloss | 60 – 80°C | Superior surface replication, longer cycle |

| Standard/Textured | 40 – 60°C | Good detail capture, balanced cycle |

| Matte Finish | < 40°C | Fastest cycle, reduced gloss |

At MTM, we ensure our clients have materials like Luran S 778T ready in China for these exact trials, avoiding delays.

Mold temperature is a powerful tool in injection molding. For Luran S 778T, it dictates the trade-off between surface gloss and production speed. Proper control ensures you achieve the desired aesthetic while maintaining efficient cycle time optimization for your project’s success.

Gate Design and Location for ASA Components

Proper gate design is crucial for high-quality ASA components, especially those with visible surfaces. The choice of gate type and its location directly impacts the final part’s appearance, influencing issues like flow marks, sink marks, and overall surface finish.

The Impact of Gating on Aesthetics

For aesthetic parts, minimizing cosmetic defects is the primary goal. An improperly placed gate can create visible blemishes that are difficult to remove post-molding. This makes the initial design phase a critical step for success.

Common Gate Types for ASA

Below is a quick overview of common gate types used for ASA materials like Luran S 778T. Each has distinct advantages and disadvantages depending on the specific application and part geometry.

| Gate Type | Advantage | Disadvantage |

|---|---|---|

| Tunnel Gate | Automatic de-gating | Can induce high stress |

| Edge Gate | Simple, low cost | Leaves a larger vestige |

| Hot Runner | Reduces waste, better flow | Higher initial mold cost |

Choosing the right gate requires balancing mold complexity, cycle time, and part quality. The decision often depends on whether the part is a visible component, where cosmetic perfection is key. At MTM, we often advise on material and process integration.

Selecting the Optimal Gate for ASA

Tunnel gates are great for automated processes but can cause high shear stress6 if not designed carefully. Edge gates are a simpler, cost-effective solution but often require a manual trimming step, which can leave a visible mark on the part.

Considering Hot Runner Systems

For large parts or high-volume production using materials like Luran S 778T, I often recommend hot runner systems. They eliminate runner scrap and allow for more precise control over the melt flow, which is essential for minimizing weld lines and other cosmetic defects.

Strategic Gate Location

The gate location is just as important as the type. Always place gates in non-critical, hidden areas of the part if possible. This directs the flow path so that any potential weld lines form in areas that are not visible to the end-user.

| Part Feature | Recommended Gate Location |

|---|---|

| Flat Surface | Center or thickest section |

| Ribbed Part | On a thick rib or non-visible edge |

| Curved Part | Along a non-cosmetic parting line |

Proper gate design for ASA is non-negotiable for achieving high-quality cosmetic parts. Selecting the right gate type and placing it strategically minimizes defects like weld lines and ensures a flawless surface finish, especially when using specific grades like Luran S 778T.

Automotive Applications: Grilles and Mirror Housings

Luran S 778T is an excellent material for automotive exterior parts like grilles and mirror housings. Its primary benefit lies in creating high-quality unpainted applications. This mold-in-color capability eliminates the entire painting process, which is a major cost and time saver for any project.

The Mold-in-Color Advantage

By using Luran S 778T, manufacturers can mold parts in their final color. This sidesteps the complexities of painting, such as managing volatile organic compound (VOC) emissions and ensuring a flawless finish. The result is a more efficient and environmentally friendly production line.

Process Simplification Comparison

| Feature | Traditional Painted Part | Luran S 778T (Unpainted) |

|---|---|---|

| Manufacturing Steps | Molding, Priming, Painting | Molding Only |

| Production Time | Longer | Shorter |

| Environmental Impact | Higher (VOCs) | Lower |

| Cost | Higher | Lower |

When clients approach us at MTM for a new side mirror housing material, they often want to move away from painted parts. Painted components are prone to chipping from road debris, and repairs are costly. Using Luran S 778T for unpainted applications is a direct solution to this problem.

Case Study: Side Mirror Housings

A common project involves developing a durable, high-gloss side mirror housing. We recommend Luran S 778T because it delivers a Class A finish directly from the mold. This eliminates the need for a separate painting line, dramatically reducing production cycle time and complexity for our clients.

The material’s inherent weather and UV resistance ensures long-term color stability. Additionally, its high level of mar resistance7 means the part can withstand minor scratches and abrasions far better than a painted surface. This resilience is critical for any automotive exterior part.

Cost and Efficiency Gains

| Cost Factor | Painted ABS/PC | Unpainted Luran S 778T |

|---|---|---|

| Scrap Rate | Higher due to paint defects | Lower |

| Labor | Molding + Painting staff | Molding staff only |

| Capital Investment | Mold + Paint line | Mold only |

| Supply Chain | Part + Paint logistics | Part logistics only |

Luran S 778T offers a significant advantage for automotive grilles and mirror housings. It enables mold-in-color production, which eliminates costly and time-consuming painting processes. This results in durable, weather-resistant parts with a superior finish straight from the mold.

Identifying Counterfeit or Off-Spec ASA in the Market

When sourcing Luran S 778T, the Certificate of Analysis (COA) is your first line of defense. However, simply receiving a COA is not enough. You must actively verify its legitimacy to avoid receiving off-spec or counterfeit resin. Generic ASA or regrind can cause significant issues during mold trials.

Prime vs. Off-Spec Material

The differences can be subtle but impactful. Prime material ensures consistent performance, while off-spec resin introduces variability that compromises trial results. This is especially true when testing high-precision molds.

| Property | Prime Luran S 778T | Off-Spec/Counterfeit ASA |

|---|---|---|

| Lot Traceability | Fully traceable lot number | Missing or inconsistent data |

| Melt Flow Rate | Within specified range | Varies significantly |

| Color Consistency | Uniform and consistent | Yellowish tint or specks |

| Mechanical Strength | Meets datasheet values | Lower impact or tensile strength |

The Risk of Assumptions

Assuming a material is genuine based on paperwork alone can lead to costly delays and inaccurate mold trial data. Diligent material verification is a crucial step in procurement.

Verifying a COA requires more than a quick glance. Start by cross-referencing the lot number and manufacturing date with the supplier. A legitimate COA will have consistent formatting and data that aligns with the manufacturer’s typical property ranges. Be cautious of values that are too perfect or identical across different batches.

Why Visual Checks Aren’t Enough

Counterfeiters have become sophisticated. A bag of resin may look correct, but its internal properties could be entirely wrong. Using regrind or a generic ASA instead of prime Luran S 778T will alter shrinkage rates, surface finish, and overall part durability. This invalidates the entire purpose of a precise mold trial. At MTM, we often help clients who faced this issue before switching to us.

Key COA Validation Steps

We advise our partners to perform a few checks to avoid counterfeit resin. Simple spectroscopy8 analysis can offer definitive confirmation of the material’s chemical makeup.

| Verification Step | Action Required | Red Flag |

|---|---|---|

| Contact Supplier | Call to confirm the lot number is valid. | Supplier cannot find the lot number. |

| Check Data | Compare properties to the official datasheet. | Values are out of spec or too perfect. |

| Review Formatting | Look for typos, logo issues, or strange fonts. | The document looks unprofessional. |

| Test Material | Perform a simple melt flow index (MFI) test. | MFI results do not match the COA. |

Ensuring you receive genuine Luran S 778T is critical. Always validate the COA and trust only reliable suppliers. This simple diligence prevents costly mold trial failures, project delays, and protects your final product quality from the start.

Color Matching and Masterbatch Compatibility

When coloring Luran S 778T, you have two primary options: using a pre-colored compound or adding a masterbatch at the press. Each method carries its own set of technical considerations. The right choice often depends on your project’s scale and specific quality requirements.

Pre-Colored vs. Self-Coloring

Pre-colored compounds provide the highest level of color consistency, as the pigment is fully dispersed by the material supplier. This is ideal for large production runs where color variation is not acceptable. Self-coloring with a masterbatch offers more flexibility for smaller batches and quick color changes.

Key Considerations

However, flexibility comes with responsibility. The compatibility of the masterbatch carrier resin with the Luran S 778T base material is critical. Using an incompatible carrier can compromise the final part’s mechanical properties and surface finish, creating unforeseen problems during mold trials.

| Method | Best For | Key Advantage | Main Challenge |

|---|---|---|---|

| Pre-Colored | Large, critical runs | Guaranteed color consistency | Higher MOQ & less flexibility |

| Masterbatch | Small batches, prototypes | Cost-effective & flexible | Requires precise dosing & compatibility |

Achieving the perfect color in Luran S 778T goes beyond just adding pigment. The entire system must work in harmony. Masterbatch compatibility is a frequent point of failure in projects I’ve seen, especially when teams try to use a generic masterbatch to save costs.

The Importance of the Carrier Resin

The carrier resin in a masterbatch must have good miscibility with the ASA base of Luran S 778T. If it doesn’t, you risk issues like delamination, surface streaks, or a reduction in impact strength. Always verify that the masterbatch is specifically designed for ASA or a compatible polymer.

Beyond Basic Compatibility

A subtle but critical issue in color matching is Metamerism9. This occurs when two colors match under one light source but not another. This can happen if the masterbatch uses different pigments than the original color standard, a common issue in automotive and electronics applications.

Based on our testing, specifying a masterbatch with an ASA-based carrier prevents most processing defects. It ensures the pigment disperses evenly without disrupting the inherent properties of the Luran S 778T material, delivering a predictable and reliable result for your mold trial.

Choosing between pre-colored Luran S 778T and a masterbatch involves a trade-off between consistency and flexibility. For reliable results, always ensure the masterbatch carrier is fully compatible with the ASA base resin to avoid compromising the final part’s integrity and appearance.

Securing Luran S 778T for Urgent Tool Validations

As a project manager, your primary concern during T0-T1 trials is eliminating delays. The biggest risk is often material availability. Sourcing small batches of Luran S 778T from overseas introduces significant uncertainty. Urgent material supply is not just a preference; it is a necessity for efficient validation.

The Small Batch Dilemma

Finding a reliable source for 25kg to 500kg of a specific grade like Luran S 778T in China can be difficult. Large distributors often prioritize bulk orders, leaving trial runs underserved. This creates a critical gap for teams needing to validate molds quickly.

| Sourcing Method | Lead Time | Cost Implication | Project Risk |

|---|---|---|---|

| Overseas Shipment | 4-8 Weeks | High shipping & duties | High (delays, customs) |

| Local Pre-Stocked | 1-3 Days | Logistics only | Low (fast, reliable) |

T0 Trial Preparation

Proper T0 trial preparation hinges on having the correct material on hand when the tool is ready. Waiting for resin is not an option. A proactive approach involves securing your Luran S 778T before the mold is even polished, ensuring a smooth transition from tooling to testing.

A Practical Strategy for Project Managers

The most effective strategy is to engage a local partner specializing in mold trial materials. At MTM, we address this specific need by pre-stocking resins like Luran S 778T. This ensures project managers can secure small batch resin supplies without international shipping headaches, customs delays, or high freight costs.

Mitigating Common Delays

The primary benefit is risk mitigation. By having the material ready in a local warehouse, you decouple your trial schedule from global supply chain variables. This simple shift in procurement strategy can save weeks on a project timeline, preventing costly overruns and keeping stakeholders satisfied with progress.

Ensuring Material Integrity

Using a trusted local supplier also guarantees you receive the exact grade specified. We understand that material consistency is crucial for validation. A Thermoplastic10 like Luran S 778T has specific processing characteristics, and using an unverified equivalent for a T0 trial introduces unnecessary variables and risks invalidating the test results.

| Step | Action | Benefit |

|---|---|---|

| 1 | Contact local supplier early | Confirms material availability |

| 2 | Specify exact grade and quantity | Ensures trial accuracy |

| 3 | Schedule local delivery | Aligns with mold completion |

| 4 | Proceed with T0 trial on time | Keeps project on schedule |

Securing small batches of Luran S 778T locally is crucial for timely T0-T1 trials. This strategy de-risks your project by eliminating international shipping delays and ensuring the specified material is ready in China, keeping your tool validation process efficient and predictable.

Secure Luran S 778T with MTM for Your Next Mold Trial

Struggling to source genuine Luran S 778T quickly in China? MTM pre-stocks certified batches—no overseas waiting, no customs headaches. Send your inquiry today and accelerate your T0-T1 validation with the right resin, right now. Don’t risk delays—contact MTM for fast, reliable supply!

-

Understand this key degradation process to better select materials for durable outdoor products. ↩

-

This concept helps predict a polymer’s stiffness and performance limits at different temperatures. ↩

-

Understand how these chemical groups cause color changes in plastics exposed to light. ↩

-

Understanding this helps predict how material properties change with flow direction in molded parts. ↩

-

Understanding rheology helps predict how a polymer fills the mold, directly impacting final part quality and aesthetics. ↩

-

Understanding this concept helps predict material behavior and prevent defects during the molding process. ↩

-

Understand how this property ensures the long-term aesthetic quality and durability of unpainted exterior components. ↩

-

Understand how spectroscopy provides a chemical fingerprint, confirming a material’s identity and purity. ↩

-

Understand how this light-dependent phenomenon impacts final product color approval. ↩

-

Understanding this property helps in selecting materials for repeatable injection molding processes. ↩