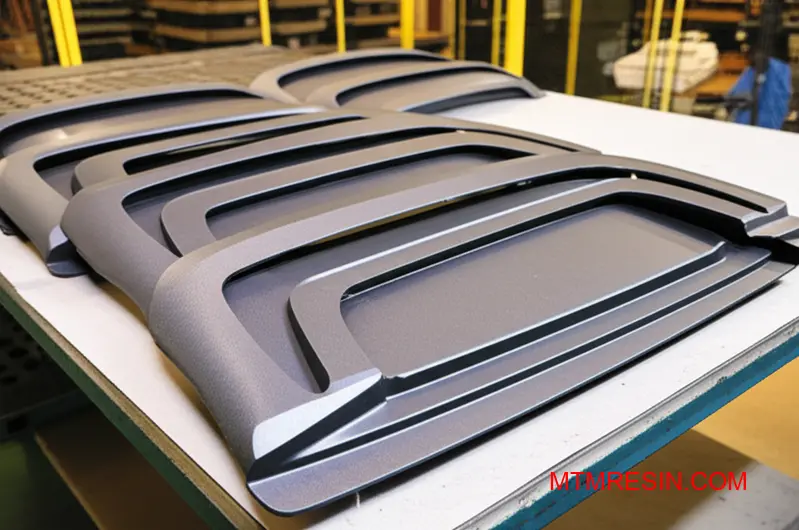

You’re deep into mold trials for an automotive exterior project in China, and your engineering team just specified Exxtral BMU 133. Now you’re facing the classic challenge: getting the exact grade to your injection molding partner without the usual 2-3 week shipping delays from Europe.

Exxtral BMU 133 is a mineral-filled polypropylene compound from Borealis specifically engineered for automotive exterior applications requiring superior impact resistance at low temperatures and dimensional stability. This grade combines excellent stiffness with crash-worthy performance, making it the preferred choice for bumpers, side cladding, and structural exterior components.

Getting your hands on genuine Exxtral BMU 133 in China doesn’t have to derail your trial schedule. I’ll walk you through the technical specifications that make this grade unique, the processing parameters that deliver consistent results, and the practical steps to secure authentic material for your mold trials without the typical supply chain headaches.

Why Global Automotive OEMs Specify Exxtral BMU 133 for Exteriors

Global automotive OEMs choose Exxtral BMU 133 for a simple reason: it hits a critical performance sweet spot. For exterior parts like bumpers, engineers need a material that is both stiff and tough. This grade delivers that balance exceptionally well.

The Engineering Sweet Spot

Exxtral BMU 133 provides high stiffness to maintain shape under load, which is essential for large panels. At the same time, it offers excellent impact resistance, a non-negotiable for safety components. This combination is challenging to achieve in polymer engineering.

Why OEMs Trust It

OEMs rely on this material because its performance is predictable. The tight Exxtral BMU 133 specification ensures consistency from batch to batch. This reliability is vital for passing stringent safety tests and maintaining brand quality standards across global production lines.

| Property | Exxtral BMU 133 Performance | Importance for Exteriors |

|---|---|---|

| Stiffness | High | Prevents sagging and deformation |

| Impact Resistance | Excellent | Absorbs energy during collisions |

| Processability | Stable | Ensures consistent part quality |

Beyond the Datasheet

The balance between stiffness and impact isn’t just a number on a technical datasheet. In practice, it translates to components that resist minor dents from road debris but also perform correctly in a crash scenario. This dual capability is what engineers look for.

Processing Stability in Mold Trials

Another key factor is its processing window. Exxtral BMU 133 is known for its stability during injection molding. This makes it a reliable choice for mold trials, which is critical when validating tooling in China. Using the exact OEM-approved grade avoids costly surprises later. Many of my clients insist on it.

Key Performance Indicators

Engineers often analyze specific metrics when evaluating automotive exterior materials. Based on our work with clients, the focus is typically on a few core areas that directly influence the final part’s success. This is where the Izod Impact Strength1 test provides critical, quantifiable data.

| Metric | Target Performance | Consequence of Failure |

|---|---|---|

| Dimensional Stability | Low Warpage | Poor panel fit and finish |

| Low-Temp. Ductility | No Cracking (-30°C) | Part failure in cold climates |

| Paint Adhesion | Excellent | Peeling, costly warranty claims |

| UV Resistance | High | Fading and material degradation |

Sourcing materials that meet every OEM resin approval can be a major hurdle for teams trying to run mold trials efficiently.

Exxtral BMU 133 provides a proven balance of stiffness and impact resistance, making it a reliable choice for automotive exteriors. Its consistent processing performance solidifies its OEM approval status, ensuring predictable results from trial to production.

Critical Physical Properties: Understanding the Datasheet Beyond the Basics

When engineers review an Exxtral BMU 133 datasheet, they often focus on a few key numbers. But these figures tell a deeper story about performance. Understanding them is crucial for successful mold trials and predicting how a part will behave in the real world.

Understanding Key Metrics

Density

The density of a material like this PP compound directly impacts the final part’s weight and, consequently, its cost. It is a fundamental property that cannot be overlooked.

Melt Flow Index (MFI)

This value indicates how easily the molten plastic flows. A proper melt flow rate analysis helps determine the right processing parameters for your injection molding machine.

Flexural Modulus

This number measures the material’s stiffness. It tells us how much a part will bend under load without breaking, which is critical for structural components.

| Property | Typical Value | Unit |

|---|---|---|

| Density | 1.04 | g/cm³ |

| Melt Flow Index (230°C/2.16kg) | 13 | g/10 min |

| Flexural Modulus (1mm/min) | 2100 | MPa |

From Numbers to Real-World Performance

The data on a spec sheet is just the starting point. Connecting these numbers to tangible outcomes is where experience comes in. For Exxtral BMU 133, these properties translate directly into processing efficiency and final part quality.

Density’s Impact on Weight and Cost

The specified PP compound density of 1.04 g/cm³ is important for lightweighting initiatives. In automotive applications, for example, every gram saved contributes to fuel efficiency. This density also allows for accurate material cost calculations per part.

Melt Flow Rate Analysis for Processing

The MFI of 13 g/10 min indicates good flowability. This makes Exxtral BMU 133 suitable for parts with intricate details or thin walls. It allows for lower injection pressures and faster cycle times, which is a direct benefit we often discuss with clients at MTM.

The Role of Flexural Modulus2 in Stiffness

A Flexural Modulus of 2100 MPa provides significant stiffness. This is one of the key mechanical properties for non-load-bearing structural parts, ensuring they maintain their shape under stress. This stiffness prevents warping and ensures dimensional stability over the product’s life.

| Metric | Impact on Processing | Impact on Part Performance |

|---|---|---|

| Density | Minimal direct impact | Determines final part weight and material cost |

| MFI | Affects injection speed, pressure, and cycle time | Influences surface finish and weld line strength |

| Flexural Modulus | No direct impact | Defines stiffness and resistance to deformation |

Understanding how density, MFI, and flexural modulus interact is key. These properties on the Exxtral BMU 133 datasheet provide a complete picture, guiding everything from tool design to final part validation, ensuring a successful project outcome.

Impact Performance at Low Temperatures: A Safety Prerequisite

The Unseen Challenge

Material performance can be deceptive. A plastic component that appears robust at room temperature might become dangerously brittle in the cold. This change in properties is a critical factor we must consider, especially for parts exposed to varying climates.

Automotive Safety Implications

For automotive components like bumpers and exterior trims, this isn’t just a quality issue; it’s a safety prerequisite. A bumper that shatters on impact in winter fails its primary function. We test materials rigorously to prevent such hazardous outcomes on the road.

| Temperature Condition | Material Behavior | Safety Risk |

|---|---|---|

| Room Temperature | Ductile, absorbs impact | Low |

| Low Temperature (-20°C) | Brittle, shatters | High |

Measuring Low-Temperature Toughness

The Charpy notched impact strength test is a standard method we use to evaluate a material’s toughness. It measures the energy a notched sample absorbs during a high-velocity impact. This test simulates how a real-world part with stress points might behave.

Why -20°C is the Benchmark

Testing at -20°C or even -30°C is crucial for automotive applications. These temperatures represent realistic winter conditions in many global markets. A material’s performance at this point reveals its true low-temperature impact resistance and reliability in harsh environments. This is a key reason materials like Exxtral BMU 133 are specified.

From Data to Real-World Safety

High Charpy impact strength at low temperatures directly correlates with auto safety compliance. It ensures a part can deform and absorb energy during a collision, rather than shattering. This behavior is fundamental to protecting vehicle occupants and passing stringent regulatory tests. Many materials undergo a ductile-to-brittle transition3 as temperatures drop, which this test is designed to identify. Our evaluations confirm that specialized grades maintain their integrity under these conditions.

Ensuring high impact performance at low temperatures is not optional. It is a fundamental requirement for auto safety compliance. Materials must be rigorously tested to guarantee they absorb impact energy effectively, protecting occupants even in the harshest winter conditions.

Mastering Shrinkage Rates for Precision Mold Design

Precision in mold design is not just about getting the shape right; it’s about predicting how the material will behave. Shrinkage is the most critical factor. Miscalculate it, and you face costly rework and project delays. Every material shrinks differently, demanding unique compensation in your tooling.

Understanding Material-Specific Shrinkage

Different polymers have distinct shrinkage rates. For instance, amorphous materials shrink less than semi-crystalline ones. Adding fillers like glass fiber or minerals, as in Exxtral BMU 133, changes this behavior dramatically, requiring careful consideration during the design phase to maintain tight mold design tolerances.

The Impact of Fillers

Mineral fillers reduce overall shrinkage but can introduce directional variations. Tooling engineers must account for this anisotropy to prevent dimensional failures.

| Material Type | Typical Shrinkage Rate | Dimensional Stability |

|---|---|---|

| Unfilled PP | 1.5% – 2.5% | Lower |

| Mineral-Filled PP/TPO | 0.8% – 1.2% | Higher |

This difference highlights why a one-size-fits-all approach to shrinkage compensation fails.

Compensating for Mineral-Filled Grades

Materials like Exxtral BMU 133 are excellent for automotive parts due to their stability. However, their mineral content introduces a challenge. The filler particles tend to align with the polymer flow direction during injection. This orientation leads to lower shrinkage along the flow path and higher shrinkage perpendicular to it.

Directional Shrinkage in Practice

This differential shrinkage is a primary cause of warpage. If your mold design assumes uniform shrinkage, the final part will not meet specifications. You must design the mold with different compensation values for the flow and transverse directions. Based on our tests, this is a common oversight leading to trial failures.

| Shrinkage Direction | Exxtral BMU 133 Rate | Design Implication |

|---|---|---|

| Parallel to Flow | ~0.8% | Less compensation needed |

| Perpendicular to Flow | ~1.2% | More compensation needed |

Ignoring this can lead to significant dimensional issues. The goal is to achieve a balanced, near-isotropic shrinkage4 behavior through strategic gate placement and processing parameter optimization. At MTM, we often advise clients on these subtleties to ensure a successful first mold trial.

Mastering precision mold design requires a deep understanding of material-specific shrinkage. For mineral-filled grades like Exxtral BMU 133, accounting for directional shrinkage is non-negotiable. Proper compensation in the design phase prevents costly dimensional failures and ensures part quality.

Optimizing Injection Molding Parameters for Exxtral BMU 133

Processing Exxtral BMU 133 requires precision. Minor deviations in injection molding parameters can significantly impact the final part’s quality. Achieving the desired surface finish and mechanical properties starts with a correctly established process. We focus on the foundational settings to avoid common defects.

Core Temperature Settings

Controlling temperature is the first step. Both the barrel and mold temperatures must be within the material’s specific processing window to ensure consistent flow and part integrity.

Recommended Temperature Profile

Based on our trials, a progressive barrel temperature profile works best for Exxtral BMU 133. This prevents material degradation while ensuring a homogenous melt.

| Zone | Recommended Temperature (°C) |

|---|---|

| Nozzle | 230 – 250 |

| Front | 230 – 250 |

| Middle | 220 – 240 |

| Rear | 210 – 230 |

Mold Temperature Control

Mold temperature directly affects shrinkage and surface aesthetics. A range of 60-80°C is generally effective.

Diving deeper into processing Exxtral BMU 133, we must consider dynamic parameters beyond static temperatures. These settings interact, and optimizing them ensures robust and repeatable production. At MTM, we supply the exact grade so your team can focus on process validation, not material sourcing.

Injection and Pressure Dynamics

Injection speed and back pressure are critical for controlling how the material fills the mold cavity. These settings directly influence the final part’s molecular orientation and internal stresses.

Injection Speed Considerations

A moderate injection speed is often the best starting point. Too fast can cause shear burn, while too slow may lead to flow marks or incomplete filling. The material’s Shear Thinning5 behavior means its viscosity decreases at higher injection speeds. This property can be leveraged for complex geometries.

The Role of Back Pressure

Back pressure is essential for a consistent melt density and removing trapped volatiles. For Exxtral BMU 133, a low-to-moderate back pressure setting is typically sufficient.

| Parameter | Recommended Setting | Purpose |

|---|---|---|

| Injection Speed | Moderate, profile as needed | Controls fill rate and surface finish |

| Back Pressure | 0.35 – 0.7 MPa | Ensures melt homogeneity, prevents voids |

| Screw Speed | 40 – 70 RPM | Gentle plasticizing, avoids overheating |

Mastering the injection molding parameters for Exxtral BMU 133 is key to producing high-quality, consistent parts. Precise control over temperature, injection speed, and pressure settings directly translates to improved surface finish and structural integrity, avoiding costly defects and rework.

Thermal Expansion Challenges in Large Exterior Assemblies

Understanding CLTE in Mixed-Material Designs

When designing large exterior automotive parts, the Coefficient of Linear Thermal Expansion (CLTE) is a critical factor. This property dictates how much a material expands or contracts with temperature changes. A significant mismatch between materials, such as plastic and metal, can cause serious issues.

The Mismatch Problem

Plastics generally have much higher CLTE values than metals. This means a plastic panel will expand more than its steel or aluminum frame in the summer heat. This differential movement can lead to stress, warping, and problems with gap and flush tolerance.

Comparative CLTE Values

The table below shows a typical comparison. We see that the plastic expands significantly more than the metals for every degree of temperature change.

| Material | Typical CLTE (10⁻⁶/°C) |

|---|---|

| Standard Polypropylene | 80 – 100 |

| Aluminum | 23 |

| Steel | 12 |

This difference is the root cause of many fit and finish problems in thermal expansion automotive parts.

Engineering Solutions for CLTE Mismatches

Managing differing CLTE values is crucial for long-term part durability. When a plastic assembly is bolted to a metal frame, temperature swings create internal stress. This can cause fasteners to loosen, parts to buckle, or even lead to cracks over time.

Advanced Material Selection

The best approach is to select a material with a CLTE closer to that of the mating metal parts. For example, materials like Exxtral BMU 133 are specifically engineered for this. Their mineral reinforcement helps lower the CLTE, reducing expansion and contraction significantly. This makes them ideal for large exterior components.

Impact on Design Tolerances

By using a low-CLTE material, you can design with tighter gap and flush tolerances. This improves the vehicle’s overall appearance and perceived quality. Based on our tests, using a material like Exxtral BMU 133 can reduce thermal-induced dimensional changes by over 50% compared to standard materials. This stability is why understanding the Coefficient of Linear Thermal Expansion6 is so vital.

| Material Feature | Standard PP | Exxtral BMU 133 |

|---|---|---|

| CLTE Value | High | Low (Closer to metal) |

| Design Risk | Warping, Stress | High Stability |

| Tolerance | Requires larger gaps | Allows tighter gaps |

At MTM, we often supply such specialized materials for mold trials. This helps teams validate their designs against thermal stress before committing to mass production, preventing costly future failures.

Managing the Coefficient of Linear Thermal Expansion is essential when combining plastics with metals in large assemblies. Choosing materials with lower CLTE values, such as Exxtral BMU 133, minimizes stress and ensures that design tolerances for gap and flush are maintained across climates.

Mitigating ‘Tiger Stripes’ and Flow Marks on Class-A Surfaces

Achieving a flawless Class-A surface is non-negotiable, especially in the automotive industry. Yet, defects like "tiger stripes" or flow marks are common frustrations during TPO/PP molding. These issues often point to an imbalance between material flow behavior and processing conditions.

Initial Troubleshooting Steps

Before diving deep, it’s crucial to address the basics. Inconsistent melt temperature or injection speed can create visible bands on the part surface. These variables are the first place I recommend teams look when troubleshooting surface aesthetics in their automotive components.

Common Causes and Checks

Here is a quick reference table based on common scenarios we’ve troubleshooted with clients. It helps isolate the root cause before making major tooling changes.

| Defect Observed | Primary Cause Suspected | Initial Action Item |

|---|---|---|

| Tiger Stripes | Unstable Melt Flow Front | Check Injection Speed Profile |

| Glossy/Dull Bands | Inconsistent Cooling/Pressure | Verify Mold Temperature Uniformity |

| Visible Flow Lines | Poor Material Rheology | Review Material Datasheet |

A Deeper Look at Rheology and Gate Design

Solving these defects requires looking beyond simple process adjustments. The material’s inherent flow characteristics, or rheology, play a massive role. An unstable flow front, often seen with highly-filled TPO, is a primary cause of tiger stripes defect issues.

How Gate Location Dictates Flow

The injection gate location is perhaps the single most critical factor in controlling surface quality. A poorly placed gate forces the molten plastic to travel in a way that creates turbulence and hesitation. Understanding a material’s Melt Flow Index7 helps predict this behavior during simulation.

Materials specifically engineered for high surface aesthetics, such as Exxtral BMU 133, have a more stable and predictable flow. This makes them less sensitive to minor process variations, which is a major benefit during mold trials where time is critical.

Gate Design’s Influence on Aesthetics

The gate’s physical design—its size and shape—also directly impacts the outcome. A gate that is too small can cause excessive shear heating, altering the material’s properties as it enters the cavity and leading to visual flaws.

| Gate Type | Typical Impact on Surface Finish | Best Use Case |

|---|---|---|

| Fan Gate | Promotes a wide, even flow front | Large, flat parts |

| Tab Gate | Reduces shear stress on the part | Shear-sensitive materials |

| Pinpoint Gate | Allows for precise location control | Multi-cavity tools |

Eliminating tiger stripes and flow marks involves a careful balance of material properties, gate design, and process parameters. Selecting a material with stable rheology from the start, like Exxtral BMU 133, can significantly simplify the troubleshooting process and accelerate project timelines.

Paint Adhesion and Surface Treatment Requirements

Engineers often ask if a part can be painted easily. For polyolefins like Exxtral BMU 133, the answer involves surface preparation. These materials have low surface energy, which naturally repels paint. Without treatment, adhesion will fail almost every time.

Why Surface Treatment is Necessary

Achieving a durable paint finish requires modifying the part’s surface. This increases its surface energy, allowing the paint to wet out and form a strong bond. It is a critical step for both aesthetic and functional coatings on polypropylene parts.

Common Treatment Methods

Several methods exist to prepare the surface. The choice depends on production volume, part geometry, and cost. Each has its own set of advantages and challenges. Below is a quick comparison.

| Treatment Method | Primary Mechanism | Best For |

|---|---|---|

| Primer/Activator | Chemical Bonding | Complex shapes, lower volumes |

| Flame Treatment | Surface Oxidation | High-speed, simple geometries |

| Plasma Treatment | Ion Bombardment | High-value, intricate parts |

This initial preparation is key to successful painting.

Proper paint adhesion is more than just applying a coating; it’s a chemical process. The low surface energy of polypropylene means liquids, including paint, tend to bead up rather than spread evenly. The goal of any treatment is to overcome this physical property.

Understanding Surface Tension

Surface tension is the force that holds liquid molecules together. For paint to stick, the substrate’s surface energy must be higher than the paint’s surface tension. Treatments effectively raise the material’s surface energy, creating a more receptive surface for the paint to bond with.

Choosing the Right Approach

For materials such as Exxtral BMU 133, using recommended Exxtral surface activators or primers is often the most reliable method. These formulations are designed to create a chemical bridge between the plastic and the paint layer, ensuring a robust connection.

Flame treatment is another option, where a controlled flame briefly touches the surface. This process oxidizes the plastic, introducing polar groups that improve adhesion. However, it requires careful process control to avoid damaging the part. Other methods like Corona discharge8 offer similar benefits for specific applications. After treatment, paint adhesion testing is essential to validate the process.

| Factor | Primer | Flame Treatment |

|---|---|---|

| Complexity | Low | High |

| Initial Cost | Low | High |

| Cycle Time | Slower | Faster |

| Consistency | High | Operator Dependent |

Achieving durable paint adhesion on polyolefin parts like Exxtral BMU 133 is entirely dependent on proper surface preparation. Selecting the right method—whether primer, flame treatment, or another technique—is crucial for meeting quality standards and ensuring long-term performance.

Risks of Using Local ‘Equivalent’ PP Instead of Genuine Exxtral

Using a "close enough" material for T0/T1 mold trials is a common but risky shortcut. The primary goal of these initial trials is to validate the mold’s design and function. Using a substitute material, even one with a similar datasheet, can render this entire process useless.

The Problem with ‘Similar’ Materials

A local equivalent PP might seem cost-effective initially. However, subtle differences in its properties compared to genuine Exxtral can lead to inaccurate test results. This invalidates the core purpose of the trial, which is to confirm the mold works perfectly with the specified production material.

Consequences of Invalid Data

Invalid data from T0/T1 trials creates a domino effect of delays and costs. Any adjustments made to the mold based on flawed information will likely need to be reversed later.

| Trial Stage | Using Genuine Exxtral | Using ‘Equivalent’ PP |

|---|---|---|

| T0/T1 Trial | Accurate mold validation | Misleading data, false positives/negatives |

| Mold Adjustments | Precise and final tuning | Incorrect modifications, rework required |

| Project Timeline | Stays on schedule | Significant delays and re-trials |

| Final Cost | Controlled and predictable | Unexpected expenses from rework |

The danger of material substitution risks goes beyond simple datasheet comparisons. Critical properties that define processing behavior are often not fully captured in standard technical data. For a specific grade like Exxtral BMU 133, the polymer architecture is unique.

How Generic PP Invalidates Mold Validation

A generic PP might have a different molecular weight distribution. This affects how the material flows into the mold, cools, and shrinks. A mold validated with this material may show issues like flash or sink marks only when you switch to the genuine Exxtral later. The mold validation accuracy is completely compromised.

The Impact on Physical Properties

We’ve seen cases where parts molded with an equivalent material pass initial dimensional checks. However, they fail stress tests because the substitute lacks the specific Crystallinity9 structure of the genuine grade. This property directly influences stiffness, impact strength, and warpage.

| Property Difference | Impact on Mold Trial |

|---|---|

| Melt Flow Variation | Incorrect fill pressure and speed settings. |

| Filler Content/Type | Affects shrinkage, warpage, and surface finish. |

| Cooling Rate Sensitivity | Leads to unpredictable warpage and dimensions. |

| Additive Package | Changes mold release and part appearance. |

At MTM, we eliminate these variables by supplying the genuine material from our China stock, ensuring your T0 trial data is reliable from the start.

Using a non-genuine material like a generic PP for early trials invalidates test data. This practice creates a false sense of security, leading to incorrect mold adjustments, project delays, and increased costs when the genuine Exxtral material is finally used.

Cycle Time Reduction Strategies Using High-Flow Grades

Optimizing the injection molding cycle time is crucial for production efficiency. Using high-flow grades like Exxtral BMU 133 can significantly shorten the filling phase. However, the real challenge often lies in the cooling phase. Faster crystallization speeds demand a smarter approach to cooling.

Crystallization and Cooling Speed

High-flow materials often crystallize faster. This property means the part solidifies more quickly, allowing for a shorter cooling time. But without proper management, this can lead to internal stresses and part warping. The key is balancing speed with control.

Cooling Time Comparison

A well-designed cooling system is essential to leverage the benefits of a material like Exxtral BMU 133. Here is a simplified comparison based on our test data.

| Material Type | Typical Cooling Phase | Potential Time Reduction |

|---|---|---|

| Standard Grade PP | 20 seconds | 0% |

| High-Flow Grade PP | 15 seconds | ~25% |

This shows that material selection directly impacts cycle time, but only if the process is adjusted accordingly.

Optimizing Cooling Channels for BMU 133

With a fast-crystallizing material like Exxtral BMU 133, the focus shifts heavily to cooling phase optimization. If cooling is uneven, some areas will shrink faster than others, causing the part to warp. This defeats the purpose of reducing cycle time.

Strategic Channel Placement

Cooling channels must be placed strategically to extract heat uniformly. This means positioning them closer to hot spots, such as thick sections or gate areas. Proper placement ensures a more isothermal10 process, minimizing differential shrinkage which is a primary cause of warpage.

At MTM, we often advise clients during their mold trials in China on how to adjust their process parameters for materials like Exxtral BMU 133. A common issue we see is a mismatch between the material’s potential and the mold’s cooling capability.

Key Cooling Design Factors

Effective cooling design requires attention to several details. Based on collaboration with our clients, we’ve found these factors to be most critical for success.

| Design Factor | Impact on Cooling | Recommendation |

|---|---|---|

| Channel Diameter | Affects coolant flow rate | Larger diameter for higher flow |

| Proximity to Surface | Controls heat extraction rate | Closer for faster, even cooling |

| Coolant Temperature | Influences crystallization speed | Lower for faster cycles, but risk of stress |

| Circuit Layout | Ensures uniform temperature | Use multiple circuits for complex parts |

Properly implementing these factors is key to unlocking shorter cycle times without sacrificing part quality.

High-flow grades like Exxtral BMU 133 offer a clear path to shorter cycle times. However, their benefits are only realized through precise cooling phase optimization. Strategic mold cooling design is essential to prevent warping and maximize production efficiency.

Dealing with Warpage in Long, Thin-Walled Bumper Applications

Warpage in long, thin-walled parts like automotive bumpers is a persistent challenge. The issue often stems from uneven cooling or material behavior. Successfully molding these components requires a deep understanding of how materials like Exxtral BMU 133 behave under specific processing conditions.

Primary Causes of Warpage

Differential cooling is a major factor. If one area of the part cools faster than another, internal stresses build up, leading to distortion. Similarly, the orientation of fillers within the plastic during injection significantly influences shrinkage and can cause warping if not managed correctly.

Key Processing Adjustments

Minor adjustments to processing parameters can have a major impact on automotive bumper warpage. Here is a quick guide based on our tests.

| Parameter | Recommended Adjustment | Expected Outcome |

|---|---|---|

| Mold Temperature | Increase uniformity | Reduced differential cooling |

| Packing Pressure | Optimize and hold | Minimized internal stress |

| Injection Speed | Decrease slightly | Controlled fiber orientation |

Dealing with Warpage in Long, Thin-Walled Bumper Applications

A technical troubleshooting guide for warpage must begin with the material itself. Materials filled with glass or mineral fibers, such as Exxtral BMU 133, are particularly susceptible to warpage if the process is not finely tuned. The challenge is balancing part integrity with dimensional stability.

Fiber Orientation and Its Effects

During injection, fibers align with the direction of melt flow. This creates different shrinkage rates parallel and perpendicular to the flow. This phenomenon, known as anisotropic shrinkage11, is a primary driver of warpage in reinforced plastics. Gate location and part geometry are critical to controlling this effect.

A Practical Approach to Warp Troubleshooting

Effective warp troubleshooting involves a systematic approach to diagnostics. By isolating variables, we can pinpoint the root cause, whether it’s related to the mold design, processing parameters, or the material itself. This iterative process is crucial for achieving residual stress reduction and a dimensionally stable part.

| Problem Area | Potential Cause | Troubleshooting Step |

|---|---|---|

| Gate Location | Unbalanced flow path | Simulate flow; adjust gate position |

| Cooling Channels | Uneven temperature | Use thermal imaging; clean channels |

| Packing Phase | Non-uniform pressure | Adjust packing profile and time |

| Material Batch | Inconsistent filler content | Verify material certificate of analysis |

Warpage in bumper applications is often due to differential cooling and fiber orientation. Effective warp troubleshooting requires controlling mold temperature, optimizing packing pressure, and managing material flow. These steps are crucial for residual stress reduction and achieving part stability.

Sustainability and Recycling: The Lifecycle of BMU 133 Parts

Corporate sustainability goals are now a major factor in material selection. Automakers want materials that perform well and support a circular economy. Exxtral BMU 133, a thermoplastic polyolefin (TPO), fits this need well. Its inherent properties make it one of the more straightforward materials to recycle automotive plastics.

Recyclability Comparison

| Feature | Exxtral BMU 133 (TPO) | Other Engineering Plastics |

|---|---|---|

| Polymer Base | Polypropylene (PP) | ABS, PC, Blends |

| Recycling Stream | Well-established | More complex separation |

| Energy to Reprocess | Relatively low | Can be higher |

| Property Retention | Good after recycling | Variable, often degrades |

This makes it a strong choice for creating sustainable automotive materials.

The recyclability of Exxtral BMU 133 is a key advantage. As a TPO, it can be mechanically recycled. This means scrap parts from production or end-of-life vehicles can be collected, ground down, melted, and reformed into new components. This process supports a circular economy for PP within the automotive industry.

Challenges in the Recycling Loop

However, real-world recycling isn’t perfect. Contamination from paints, coatings, and other plastics can reduce the quality of the recycled material. To address this, advanced recycling methods are gaining traction. These chemical processes can break down the plastic into its basic building blocks.

Advanced Recycling Options

One such method is Pyrolysis12. This process can handle mixed plastic waste more effectively than mechanical recycling. It converts the plastic back into a raw oil, which can then be used to produce new, virgin-quality plastics. This creates a truly closed loop for materials like Exxtral BMU 133. At MTM, we advise clients on how material choices made today impact future recycling streams.

| Recycling Stage | Key Consideration |

|---|---|

| Collection | Efficient sorting of plastic types |

| Processing | Removal of contaminants like paint |

| Repelletizing | Ensuring consistent quality of recyclate |

| Re-use | Application in non-critical parts first |

Exxtral BMU 133’s composition makes it a prime candidate for recycling, supporting corporate sustainability goals. Its integration into a circular economy framework helps reduce waste and promotes the reuse of valuable materials within the automotive supply chain.

Comparing Exxtral BMU 133 to Standard Impact Copolymers

When selecting materials, project engineers often ask why they should specify a premium grade like Exxtral BMU 133. A standard impact copolymer might seem sufficient and more cost-effective. However, the decision depends entirely on the application’s demands.

Key Performance Differentiators

Exxtral BMU 133 is an engineered polypropylene compound. It is specifically formulated with a unique additive package. This package delivers superior performance that standard grades cannot match, especially in demanding automotive or industrial parts.

A Head-to-Head Look

Here is a simple comparison based on our test results with clients. This helps clarify why the engineering resin selection process is so critical for project success.

| Feature | Exxtral BMU 133 | Standard Impact Copolymer |

|---|---|---|

| Stiffness | High | Moderate |

| Impact Strength | Excellent, esp. at low temps | Good at room temp, brittle when cold |

| Surface Finish | High gloss, scratch-resistant | Standard, prone to scuffing |

| Dimensional Stability | Very High | Moderate |

The real value of Exxtral BMU 133 lies in its sophisticated additive package. This is not just a simple polypropylene; it’s a carefully balanced system. Standard copolymers offer baseline impact resistance, but this Borealis grade is designed for consistency and reliability under stress.

Beyond Basic Properties

The additives in Exxtral BMU 133 provide critical benefits. For instance, its filler system offers high stiffness and very low, uniform shrinkage. This is crucial for large parts requiring tight tolerances. Standard materials often exhibit unpredictable shrinkage, leading to warping and fitment issues during assembly. This can cause significant delays during mold trials.

The Role of Specialized Additives

The formulation includes advanced nucleating agents13 that control the crystallization process. This results in a finer, more uniform polymer structure. The outcome is improved mechanical strength and a better surface finish straight from the mold. Getting the right material, like the exact Exxtral BMU 133 grade, is why our clients use MTM. We ensure they are testing the final production material from day one.

When we compare Borealis Exxtral vs standard PP, the choice is about risk management. The higher initial cost of an engineered resin often prevents costly tool modifications and production delays later on.

Exxtral BMU 133 justifies its cost through superior stiffness, impact resistance, and dimensional stability. Standard copolymers are suitable for less demanding roles, but for critical applications, the engineered grade ensures reliable performance and a smoother production launch.

Verifying Material Authenticity at Your Chinese Injection Partner

Ensuring your Chinese partner uses the specified resin is critical. You can’t just trust; you must verify. The process starts with documentation and physical checks. This combination of paperwork and hands-on inspection forms the first line of defense against material substitution.

The Power of Paperwork

Always request the Certificate of Analysis (COA) for the specific batch of material. This document provides key data points from the manufacturer. It’s your baseline for what to expect from the resin’s performance and properties during the molding process.

Physical Bag Verification

Don’t overlook the obvious. Inspect the resin bags upon arrival at the facility. Check for original manufacturer markings, correct grade labels, and lot numbers. These details should match the COA you received. Any discrepancies are a major red flag.

| Verification Step | Key Focus Area | What to Look For |

|---|---|---|

| Documentation | Certificate of Analysis (COA) | Batch/Lot Number, Key Properties, Manufacturer Name |

| Bag Inspection | Original Packaging | Intact Seals, Correct Branding, Grade Label |

| Label Matching | Cross-Reference | Ensure Bag Lot Number matches the COA |

Beyond Basic Checks

A Certificate of Analysis is a good starting point, but it’s not foolproof. A determined supplier could provide a legitimate COA while using a different, cheaper material. This is why a multi-layered approach is essential for critical components, especially those using performance materials like Exxtral BMU 133.

Conducting a Supplier Audit

A robust supplier audit in China involves more than just reviewing documents. You should request a material sample from the exact batch intended for your project. This sample can be sent to a third-party lab for independent verification if the application is highly sensitive. This step provides definitive proof.

Another practical measure is to ask for photos of the material bags on-site, with a timestamp or a unique identifier visible. While not perfect, this adds another layer of accountability. For ultimate assurance, advanced techniques like Spectroscopy14 can create a chemical fingerprint of the material, which is then compared against a known-good sample.

| Verification Method | Reliability | Cost |

|---|---|---|

| Document Review (COA) | Medium | Low |

| Visual Bag Check | Medium | Low |

| 3rd Party Lab Testing | High | Medium-High |

| On-Site Sample Taking | High | High (Travel) |

Verifying resin authenticity is a non-negotiable step. Combine documentation review, physical inspection of bags and markings, and consider third-party testing for critical projects. This diligence protects your project timeline, budget, and final product quality, ensuring you get exactly what you specified.

Secure Your Exxtral BMU 133 Supply with MTM Today

Looking to run reliable, on-time mold trials with Exxtral BMU 133 in China? Don’t risk delays or non-genuine material—contact MTM for immediate access to genuine Exxtral BMU 133, pre-stocked locally. Send your inquiry now and ensure smooth, validated automotive mold trials every time!

-

Understanding this test helps quantify a material’s ability to withstand sudden impacts, crucial for component durability. ↩

-

Understand how this core material property dictates component stiffness and structural integrity in engineering applications. ↩

-

Understanding this concept helps predict material failure in varying temperature environments. ↩

-

Understanding this concept helps predict material behavior and prevent part warpage. ↩

-

Understanding this concept helps optimize injection speeds for complex parts and material flow behavior. ↩

-

Understanding this property helps engineers predict material behavior and design more durable, stable assemblies. ↩

-

Explore this metric to better predict how a polymer will behave during the injection molding process. ↩

-

Learn how this electrical process modifies polymer surfaces for industrial printing and bonding applications. ↩

-

Understand how this polymer property impacts part shrinkage, strength, and final product performance. ↩

-

Understanding this concept helps in designing cooling systems for uniform part quality and reduced stress. ↩

-

Understanding this concept helps predict how the material will behave during molding for better part quality. ↩

-

Learn how this thermal process breaks down plastics into valuable raw materials for a circular economy. ↩

-

Discover how these agents refine polymer structure to enhance final part properties and processing speed. ↩

-

Explore how this method offers scientific proof of a polymer’s chemical identity, safeguarding material integrity. ↩