STAMAX 30YM240 presents unique challenges that can derail even experienced molding projects. Engineers often struggle with fiber breakage, unexpected warpage, and surface defects when transitioning from standard polypropylene to this long glass fiber composite.

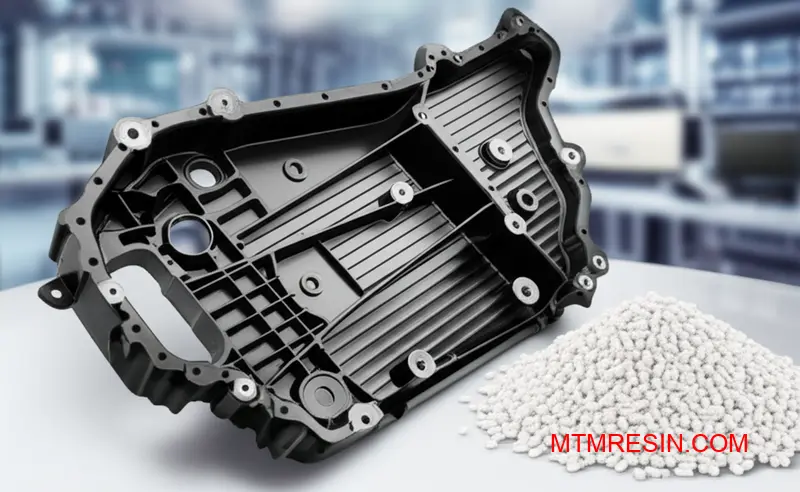

STAMAX 30YM240 is a 30% long glass fiber reinforced polypropylene designed for structural applications requiring metal-like strength with significant weight reduction. Success depends on specialized processing techniques that preserve fiber length and control orientation.

I’ve worked with engineering teams facing these exact molding challenges. The difference between a smooth trial run and costly delays often comes down to understanding the specific requirements of long glass fiber processing. Let me walk you through the technical considerations that will help you avoid common pitfalls and achieve consistent results with this demanding material.

Why Engineers Specify STAMAX 30YM240 For Structural Parts

Engineers select STAMAX 30YM240 for its unique balance of strength, stiffness, and low density. This long glass fiber polypropylene (PP) is a top choice for metal replacement in automotive and industrial parts. It enables significant weight reduction without sacrificing structural integrity.

The Advantage of Long Glass Fiber

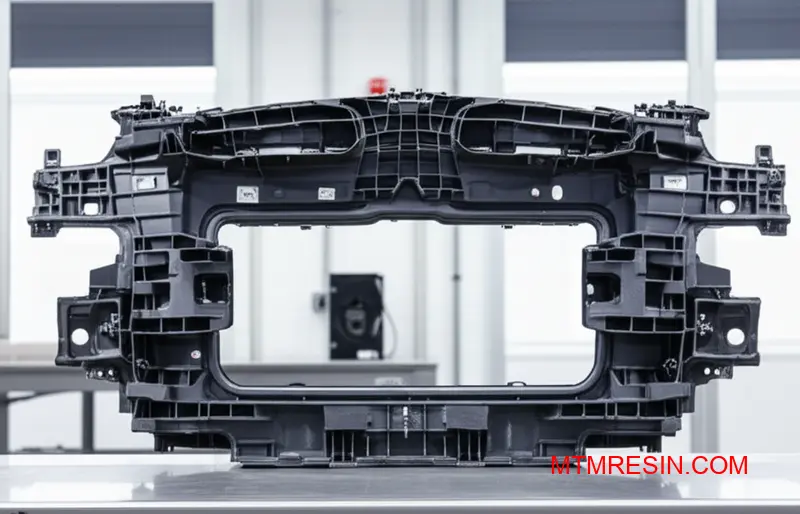

Unlike short glass fiber materials, the long fibers in STAMAX 30YM240 form an internal skeletal structure. This network delivers superior mechanical properties, especially in demanding applications like front-end modules, door modules, and battery trays. The result is a robust, lightweight component.

Performance at a Glance

Our analysis shows that its performance metrics make it a strategic material for modern engineering challenges. Automotive lightweighting goals are more achievable with materials like this.

| Property | STAMAX 30YM240 (Typical) | Mild Steel (Typical) |

|---|---|---|

| Density (g/cm³) | ~1.12 | ~7.85 |

| Tensile Modulus (MPa) | ~7500 | ~200,000 |

| Impact Strength | High | Very High |

This combination makes STAMAX 30YM240 a go-to structural thermoplastic.

The decision to use STAMAX 30YM240 extends beyond simple material specifications. It involves considering the entire production cycle, from design and molding to final assembly. Its excellent flow characteristics allow for the creation of complex geometries that would be difficult or costly to produce with metal stamping or casting.

Design and Processing Flexibility

This material offers designers greater freedom. Features like ribs and bosses can be integrated directly into the mold, reducing the need for secondary assembly operations. This simplifies the manufacturing process and lowers overall costs. We see this benefit in many projects requiring intricate structural components.

Consistency in Mold Trials

One critical factor is material consistency during mold trials. Using the exact specified grade, like STAMAX 30YM240, is essential for validating a tool. At MTM, we stock this material in China so teams can avoid international shipping delays and ensure their trials accurately reflect production conditions. The material’s behavior is influenced by its fiber orientation, a property known as anisotropy1.

| Parameter | Guideline | Benefit |

|---|---|---|

| Melt Temperature | 230-260 °C | Optimal fiber dispersion |

| Mold Temperature | 40-70 °C | Good surface finish & stability |

| Injection Speed | Moderate to High | Minimizes fiber breakage |

Predictable processing behavior helps engineers achieve part consistency from the first shot.

STAMAX 30YM240 is a leading choice for structural parts due to its superior strength-to-weight ratio, design flexibility, and reliable processability. It empowers engineers to meet automotive lightweighting targets without compromising on performance, making it a valuable asset in modern product development.

Analyzing The Mechanical Property Profile Of STAMAX 30YM240

STAMAX 30YM240 is a popular choice for structural components, but its name reveals much about its performance. The "30" signifies a 30% long glass fiber reinforcement, which is key to its enhanced mechanical properties. The "YM240" designation provides further clues about its specific grade characteristics.

Decoding the Grade

Understanding these codes is the first step in material selection. It helps project engineers quickly assess if the material is a potential fit before diving into the full datasheet. This initial check saves valuable time during the design phase.

Key Identifiers

| Code | Meaning | Implication |

|---|---|---|

| STAMAX | Brand Name | SABIC’s LGFPP |

| 30 | Glass Fiber % | 30% Long Glass Fiber |

| YM240 | Grade Series | Specific performance/flow |

This breakdown allows for a quick assessment of the material’s core composition. It immediately tells us we are dealing with a reinforced polypropylene intended for demanding applications.

When we analyze the datasheet for STAMAX 30YM240, three properties stand out for structural applications. These are the pillars that define its performance under stress and heat, which are critical considerations for automotive and industrial parts.

Core Mechanical Properties

The 30% long glass fiber significantly boosts stiffness and strength. Its Tensile Modulus2 is much higher than unfilled polypropylene, meaning it resists bending under load. This is a critical factor for parts that must maintain their shape.

Impact and Heat Resistance

The material also shows excellent impact strength, often measured by Izod or Charpy tests. The long fibers help distribute impact energy, preventing catastrophic failure. Furthermore, its Heat Deflection Temperature (HDT) is elevated, allowing it to perform reliably in high-temperature environments.

Datasheet Snapshot: STAMAX 30YM240

| Property | Typical Value | Significance |

|---|---|---|

| Tensile Modulus | ~7500 MPa | High stiffness, resists flex |

| Notched Izod Impact | ~15 kJ/m² | Good toughness and durability |

| HDT (0.45 MPa) | ~155 °C | Stability at high temps |

At MTM, we stock STAMAX 30YM240 in China precisely because these properties are frequently required for mold trials. Having it ready avoids delays, ensuring our clients can validate their designs with the exact specified material without waiting for overseas shipments.

Understanding the STAMAX 30YM240 datasheet is vital for predicting its real-world performance. The 30% glass fiber provides exceptional stiffness, impact resistance, and thermal stability, making it a reliable choice for structural parts that require robust mechanical properties.

Long Glass Fiber (LGF) Vs. Short Glass Fiber: Performance Gaps

When selecting a glass-filled polypropylene, the choice between long fiber (LGF) and short fiber (SGF) is critical. The primary difference is the length of the glass fibers embedded within the polymer matrix. This directly impacts the final part’s structural integrity and overall performance characteristics.

The Core Difference: Fiber Length

Short fibers are typically under 1 mm, while long fibers in LGF can be over 10 mm. This longer length creates a more robust internal "skeleton" within the plastic. This structure significantly enhances mechanical properties compared to materials reinforced with shorter fibers.

Initial Performance Comparison

A quick look shows clear trade-offs. While SGF offers ease of processing and lower costs, LGF provides a substantial boost in key mechanical areas. Our clients often test both to quantify the benefits for their specific applications.

| Property | Short Glass Fiber (SGF) | Long Glass Fiber (LGF) |

|---|---|---|

| Impact Strength | Moderate | High to Very High |

| Tensile Strength | Good | Excellent |

| Creep Resistance | Fair | Excellent |

| Warpage | Lower | Higher (if not controlled) |

Let’s focus on a specific material: STAMAX 30YM240, a 30% long glass fiber polypropylene. When engineers compare it to a standard 30% short glass fiber PP, the performance gap becomes evident. It’s not just about simple strength; it’s about durability over time.

Why STAMAX 30YM240 Excels

The interconnected network of long fibers in STAMAX 30YM240 provides superior energy absorption. This makes it ideal for parts that must withstand impacts, like automotive bumpers or industrial housings. Short fibers simply cannot distribute impact forces as effectively across the part.

Furthermore, its creep resistance is significantly better. Under constant load, especially at elevated temperatures, parts made from SGF-PP will deform. The long fiber skeleton in LGF-PP resists this slow deformation, ensuring long-term dimensional stability for critical structural components. This is a direct result of the material’s viscoelasticity3 behavior.

Justifying the Cost Premium

Yes, LGF materials like STAMAX 30YM240 have a higher initial cost. However, this cost is often justified by avoiding part failure, reducing weight by designing thinner walls, and extending product life. For our customers, we make sourcing trial quantities of such specialty materials in China simple.

| Performance Metric | SGF-PP (30%) | STAMAX 30YM240 (30% LGF-PP) |

|---|---|---|

| Notched Impact Strength | Lower | ~3-5x Higher |

| Long-Term Creep | Higher Deformation | Significantly Lower |

| Dimensional Stability | Good | Excellent |

Choosing LGF-PP like STAMAX 30YM240 is an investment in long-term performance. The enhanced impact strength, creep resistance, and stability often outweigh the initial material cost, especially for demanding structural applications where failure is not an option.

Metal Replacement Strategies Using STAMAX 30YM240

STAMAX 30YM240 is a key material for replacing metal in automotive parts. This 30% long glass fiber polypropylene offers a smart balance of strength, stiffness, and low density. It allows engineers to design lighter components without sacrificing performance, a critical goal in modern vehicle manufacturing.

From Metal to Plastic

Replacing steel or aluminum with this material offers direct benefits. Consider these common automotive applications. Our clients often see substantial improvements when they make the switch.

| Component | Traditional Material | STAMAX 30YM240 Advantage |

|---|---|---|

| Front-End Carrier | Stamped Steel | 30-40% Weight Reduction |

| Door Module | Aluminum/Steel | Part Consolidation |

| Instrument Panel | Steel Frame | Improved Design Freedom |

This strategic shift helps reduce overall vehicle weight. It also simplifies the manufacturing process, leading to potential cost savings and greater efficiency on the assembly line.

Key Automotive Applications

In front-end carriers, STAMAX 30YM240 allows for the integration of multiple metal brackets and supports into a single molded part. This consolidated parts assembly approach reduces complexity, fastener count, and labor time. The result is a lighter, yet robust, structural component.

For door modules, weight reduction is a primary driver. A lighter door improves fuel economy and handling. We’ve seen clients achieve up to a 50% weight saving on the structural carrier alone. This is a significant gain when applied across all doors. The material’s Creep resistance4 is also vital here.

Instrument Panel Design

Instrument panels benefit from the design flexibility of STAMAX 30YM240. Engineers can create complex geometries that integrate HVAC ducts and mounting points directly into the main structure. This is nearly impossible with stamped metal, leading to fewer parts and a faster assembly process.

| Application | Key Benefit | Typical Outcome |

|---|---|---|

| Front-End Carrier | Part Integration | Lower Assembly Cost |

| Door Module | Weight Reduction | Better Fuel Efficiency |

| Instrument Panel | Design Freedom | Simplified Production |

At MTM, we stock STAMAX 30YM240 in China. This helps our partners get materials quickly for mold trials, validating these complex designs without international shipping delays.

STAMAX 30YM240 is a powerful tool for replacing metal in automotive modules. It enables significant weight reduction through lower density and cost savings through parts consolidation. This makes it a strategic choice for efficient and modern automotive module design.

Optimizing Screw Design For Long Glass Fiber Retention

When working with long glass fiber (LGF) polypropylene like STAMAX 30YM240, the screw design is critical. Standard screws often cause significant fiber breakage during plasticizing. This damage directly compromises the mechanical properties of the final molded part, undermining the very reason for choosing an LGF material.

The Problem with Standard Screws

Standard screws typically have high compression ratios. This design generates intense shear and pressure, which is effective for general-purpose plastics but destructive for LGF composites. The fibers are ground down as they travel along the screw, losing their length and reinforcing capability before ever reaching the mold.

Impact of Fiber Breakage

Shorter fibers lead to a sharp decline in impact strength and stiffness. The part will not perform as designed. I’ve seen projects fail because the processing equipment was not optimized for the material. The material itself was not the problem; the machinery setup was the culprit.

| Screw Type | Fiber Length Retention | Resulting Part Performance |

|---|---|---|

| Standard GP Screw | Low | Brittle, below spec |

| Optimized LGF Screw | High | Strong, meets requirements |

To preserve fiber length, a specialized plasticizing unit is essential. The solution lies in using a low-compression screw. This design minimizes shear forces, allowing the fibers to pass through the barrel with far less damage. It ensures the material’s integrity is maintained from pellet to part.

The Low-Compression Screw Advantage

A screw with a low compression ratio (typically around 2:1) provides a gentler conveying action. It reduces the pressure buildup in the transition zone, which is where most fiber damage occurs. When clients trial materials like STAMAX 30YM240 from our stock at MTM, I always emphasize checking the screw specifications.

Non-Return Valve Selection is Crucial

The non-return valve (or check valve) is another potential source of fiber breakage. A sliding check ring valve is the most common but can create high shear and pinch fibers. A free-flow or ball-check non-return valve is a much better choice. These designs offer a less restrictive path for the material. Understanding the material’s Rheology5 helps in predicting its behavior under different processing conditions.

| Valve Type | Fiber Damage Risk | Recommended Use |

|---|---|---|

| Sliding Check Ring | High | General Purpose Plastics |

| Free-Flow Valve | Low | LGF & Sensitive Materials |

| Ball Check Valve | Low | LGF & Sensitive Materials |

Optimizing screw design is non-negotiable for LGF materials. Standard screws degrade fiber length, reducing part performance. Using low-compression screws and free-flow non-return valves preserves the integrity of materials like STAMAX 30YM240, ensuring the final product meets its mechanical specifications.

Processing Temperatures And Injection Speeds For 30YM240

Achieving optimal results with STAMAX 30YM240 requires precise control over processing parameters. The right settings ensure good material flow while protecting the long glass fibers from damage. Incorrect temperatures or speeds can compromise the final part’s mechanical properties.

Recommended Temperature Profile

We recommend a specific temperature profile for the barrel to ensure a consistent melt. Start with a lower temperature at the rear and gradually increase it toward the nozzle. This prevents premature melting and material degradation.

Barrel and Mold Temperatures

A stable mold temperature is equally critical. It directly influences surface finish, shrinkage, and cycle times. Here are the typical settings we advise clients to start with.

| Parameter | Recommended Range |

|---|---|

| Rear Zone Temperature | 220-240°C (428-464°F) |

| Middle Zone Temperature | 230-250°C (446-482°F) |

| Front Zone Temperature | 240-260°C (464-500°F) |

| Nozzle Temperature | 250-270°C (482-518°F) |

| Mold Temperature | 70-90°C (158-194°F) |

Injection Speed Considerations

Injection speed for STAMAX 30YM240 must be managed carefully. A moderate to high speed is often needed to fill the part quickly. However, excessive speed can damage the glass fibers, which is the key to this material’s strength.

Diving deeper, the challenge with STAMAX 30YM240 molding conditions is balancing two opposing factors. You need enough heat and speed for the material to flow easily into complex mold cavities. Yet, too much of either will degrade the polymer or break the long glass fibers.

The Risk of Fiber Damage

High injection speeds increase the shear rate6, which can fracture the glass fibers. When fibers are shortened, the material loses its intended structural strength. After working with our clients, we’ve found that a multi-stage injection profile often works best. It starts slower and then speeds up.

Finding the Sweet Spot

There is no single "perfect" setting. It always depends on the part geometry, wall thickness, and gate design. We always start with the manufacturer’s data sheet but fine-tune based on the actual mold trial results. Below is a simple guide on what to watch for.

| Setting Issue | Potential Consequence | Recommended Action |

|---|---|---|

| Temperature Too Low | Short shots, poor surface | Increase barrel temperature slightly |

| Temperature Too High | Material degradation, discoloration | Lower barrel and nozzle temps |

| Speed Too High | Fiber breakage, flash | Reduce injection speed, use stages |

| Speed Too Low | Flow marks, incomplete fill | Increase injection speed moderately |

This iterative process is where experience matters. At MTM, we supply the material and provide the support to get these processing parameters right, ensuring your trial runs are successful without unnecessary delays.

Finding the correct processing parameters for STAMAX 30YM240 is a balancing act. You must ensure good flow without causing thermal degradation or fiber damage. Precise control over barrel temperatures, mold temperature, and injection speed is essential for optimal part quality.

Material Handling: Drying And Feeding LGF Granules

Handling long glass fiber (LGF) granules like STAMAX 30YM240 presents unique challenges compared to standard pellets. The first question I often get is about drying. Polypropylene (PP) itself doesn’t absorb much water, but that’s not the full story.

The Real Reason for Drying

The main issue is surface condensation. If you bring cold pellets into a warm, humid molding environment, moisture will form on their surface. This can cause splay marks on the final part. Proper material handling of PP with long fibers requires this extra step.

Drying Recommendations

| Material | Drying Required? | Reason |

|---|---|---|

| Standard PP Pellets | Generally No | Low moisture absorption |

| LGF PP Pellets (e.g., STAMAX) | Yes, often | To remove surface condensation |

A short pre-drying cycle is a good practice to ensure a consistent, high-quality molding process, especially in humid conditions.

Beyond drying, the physical shape of LGF pellets creates another major hurdle: feeding them into the machine. The long, rod-like shape of these granules can easily cause them to interlock and form an arch inside the hopper, a problem known as bridging.

Preventing Hopper Bridging

Hopper bridging stops material flow, starving the screw and causing inconsistent shots. This is a common issue with STAMAX pellet feeding. While the polypropylene base is hydrophobic7, the physical form of the pellets is the primary concern for material handling.

Solutions for Smooth Feeding

The key is to keep the material moving. Standard hoppers with shallow cone angles often make the problem worse. Instead, specialized equipment can solve this. Based on our tests with clients, certain adjustments are highly effective.

| Method | Description | Effectiveness |

|---|---|---|

| Steep Hopper Angle | Use hoppers with a cone angle greater than 60° | High |

| Mechanical Agitators | A slow-moving paddle or arm gently stirs the pellets | Very High |

| Vibratory Feeders | Gentle vibration helps pellets settle and flow | Moderate to High |

At MTM, we often advise clients using materials like STAMAX 30YM240 to review their feeding setup. The right equipment prevents costly downtime and ensures a stable process.

Properly handling LGF pellets requires drying to prevent surface condensation and using steep-angled hoppers or mechanical aids to avoid bridging. These steps are crucial for a stable molding process and high-quality parts with materials like STAMAX 30YM240.

Controlling Anisotropy And Fiber Orientation In Molded Parts

Understanding fiber orientation is critical for part performance. When using fiber-reinforced materials, the direction of the fibers dictates the part’s strength. Mechanical properties are not uniform in all directions, creating what we call anisotropic properties. This is a key factor to manage.

Strength Along vs. Across Fibers

A part’s strength is highest along the direction of fiber alignment (longitudinal) and weakest perpendicular to it (transverse). This difference can be significant. Ignoring it often leads to unexpected part failures in the field, a problem I’ve seen many times.

Property Comparison

| Property | Longitudinal (Along Fibers) | Transverse (Across Fibers) |

|---|---|---|

| Tensile Strength | High | Low |

| Stiffness | High | Low |

| Shrinkage | Low | High |

Controlling this orientation becomes the main task for achieving design specifications.

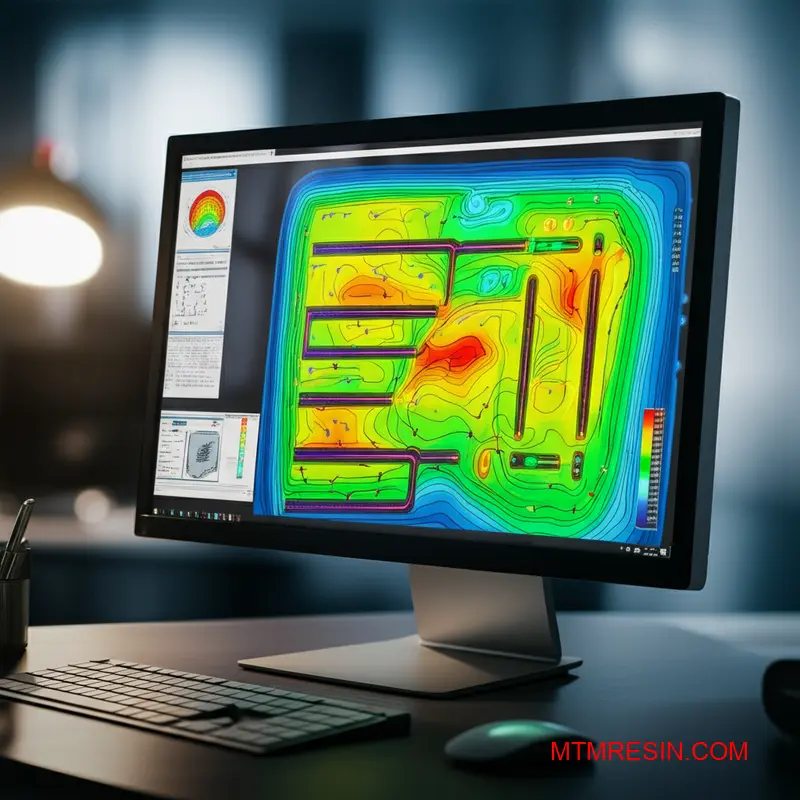

To achieve effective fiber orientation control, we must move from guesswork to prediction. This is where modern engineering tools become essential. Relying on experience alone is not enough, especially with complex geometries and high-performance materials like STAMAX 30YM240.

Using Mold Flow Analysis

Mold flow analysis is our primary tool for predicting how the plastic will fill the mold. The simulation shows the melt front progression, which directly influences how fibers align. We can visualize the final fiber orientation before cutting steel, saving significant time and cost.

Predicting Warpage

Warpage is often the direct result of uncontrolled anisotropic properties. The primary cause is differential shrinkage8, where the part shrinks more in the transverse direction than in the longitudinal direction. This uneven shrinkage creates internal stresses that distort the part as it cools.

| Analysis Input | Predicted Output |

|---|---|

| Gate Location | Fiber Orientation Map |

| Process Parameters | Shrinkage Rates |

| Material Data | Warpage Prediction |

At MTM, we supply the exact materials, like STAMAX 30YM240, that clients use for these simulations. This ensures the analysis is based on accurate data, making the warp prediction reliable and the mold trial successful from the first shot.

Mastering fiber orientation is key to unlocking the full potential of reinforced polymers. Using mold flow analysis helps predict and control these anisotropic properties, preventing issues like warpage and ensuring the final part meets strength requirements for materials such as STAMAX 30YM240.

Managing Shrinkage And Warpage In Large Structural Components

When working with dimensionally critical parts, especially large ones, material choice is everything. The shrinkage rate of STAMAX 30YM240, a 30% long glass fiber polypropylene, requires precise control. Its behavior is predictable but demands attention to detail during the molding process to avoid costly errors later.

Understanding Material Behavior

STAMAX 30YM240 exhibits different shrinkage rates depending on the direction of material flow. This is a critical factor in controlling warpage. Understanding these values from the start allows for better mold design and process parameter setup. This knowledge is fundamental for achieving dimensional stability.

Initial Parameter Settings

For a material like STAMAX 30YM240, establishing a baseline is key. We often start with the material supplier’s recommendations and adjust from there. The following table shows typical shrinkage values our clients work with.

| Direction | Typical Shrinkage Rate |

|---|---|

| Flow Direction | 0.2% – 0.4% |

| Cross-Flow Direction | 0.6% – 0.9% |

These initial settings provide a solid starting point for cooling time optimization.

Controlling warpage in large components made from STAMAX 30YM240 goes beyond initial settings. It involves a systematic troubleshooting process. Having the exact material available locally through MTM allows our clients to perform these iterative tests efficiently without waiting for overseas shipments.

Adjusting Packing Pressure

Packing pressure directly compensates for material shrinkage as the part cools. For STAMAX 30YM240, insufficient packing can lead to sinks and voids. Conversely, excessive pressure can cause flash or stress, which also contributes to warpage. Finding the right balance is crucial.

Cooling Time Optimization

Cooling time must be sufficient for the part to solidify and become stable before ejection. With large parts, this is even more critical. Shortening the cycle is tempting, but premature ejection will lock in stress and cause dimensional problems. The goal is to find the shortest time that still guarantees part stability. This is directly related to Volumetric Shrinkage9.

| Parameter Adjustment | Effect on Dimensions | Risk |

|---|---|---|

| Increase Packing Pressure | Reduces Shrinkage | Potential for Flash, High Stress |

| Decrease Packing Pressure | Increases Shrinkage | Sinks, Voids, Under-dimension |

| Increase Cooling Time | Improves Stability | Longer Cycle Time |

| Decrease Cooling Time | Worsens Warpage | Post-mold Deformation |

This iterative process of adjusting pressure and time is fundamental to achieving tight tolerances.

Achieving tight tolerances with STAMAX 30YM240 hinges on balancing packing pressure and cooling time. This precise control is key to managing its specific shrinkage rate and ensuring final part dimensional stability. Effective troubleshooting requires a data-driven approach to these critical parameters.

Addressing Surface Finish Challenges With Glass-Filled PP

The "floating fiber" effect is a well-known aesthetic challenge with long-glass-fiber materials. It occurs when glass fibers appear on the part’s surface, creating a swirled or matte look instead of a smooth, uniform finish. This is particularly problematic for components where appearance is critical.

The Source of the Issue

This phenomenon is inherent to the nature of glass-filled polypropylene. During injection, the less viscous polymer melt flows faster than the fibers, especially near the mold wall. This can leave fibers exposed as the part cools, affecting the final glass fiber surface appearance.

Initial Troubleshooting Steps

Before exploring advanced methods, some basic process adjustments can offer improvement. However, these alone are often insufficient for achieving a premium, Class A surface. Here are some starting points we often discuss with clients.

| Surface Issue | Common Cause | Initial Solution |

|---|---|---|

| Floating Fibers | Low melt temperature | Increase melt temperature |

| Swirl Marks | Inconsistent fill speed | Optimize injection speed profile |

| Dull Finish | Low mold temperature | Increase mold surface temperature |

Achieving a Class A Surface

When a flawless, high-gloss finish is non-negotiable, we must move beyond standard process tweaks. Achieving a Class A surface with materials like STAMAX 30YM240 requires more sophisticated molding techniques that directly address the root cause of floating fibers.

High Mold Temperatures

One effective strategy is significantly increasing the mold surface temperature. A hotter mold allows a resin-rich layer to form at the surface, effectively burying the glass fibers beneath a smooth polymer skin. This improves the surface finish but can also extend cycle times.

Dynamic Mold Heating

For the most demanding applications, dynamic mold heating and cooling is the premier solution. This process involves rapidly heating the mold cavity surface just before injection and then quickly cooling it to solidify the part. This ensures optimal surface replication and hides fibers completely. This helps prevent surface defects like Marring10 during handling and use.

| Technique | Principle | Best For |

|---|---|---|

| High Mold Temperature | Creates a resin-rich surface layer | Improving gloss and hiding minor fibers |

| Dynamic Mold Heating | Rapid heating/cooling cycle | Achieving Class A finishes |

| Gas-Assist Molding | Hollows out sections, pushes resin to surface | Large parts with complex geometry |

Floating fibers are a common issue with glass-filled PP. While basic process adjustments can help, achieving a Class A surface on materials like STAMAX 30YM240 often requires advanced techniques like high or dynamic mold temperatures to create a smooth, resin-rich skin.

Tool Wear Mitigation When Molding 30% Glass Fiber

Molding materials with 30% glass fiber, like STAMAX 30YM240, presents a significant challenge: abrasive wear on the mold. The glass fibers act like fine sandpaper, gradually eroding critical tool surfaces, especially in high-wear areas like gates and sharp corners. This accelerates tool degradation.

Core Defense: Mold Steel Selection

Choosing the right mold steel is your first and most important defense. Standard P20 steel is simply not durable enough for high-volume production with such materials. Hardened tool steels are essential for prolonging tool life and maintaining part quality over time.

Steel Comparison for Abrasive Applications

| Steel Type | Hardness (HRC) | Wear Resistance | Toughness | Recommendation |

|---|---|---|---|---|

| P20 (Pre-hardened) | ~30-34 | Low | High | Not for high volume |

| H13 (Hardened) | ~48-52 | Good | Good | Good starting point |

| S7 (Hardened) | ~54-56 | Very Good | Excellent | For high-impact areas |

| CPM Series | ~58-62 | Excellent | Good | Best for critical inserts |

While selecting a high-hardness steel is fundamental, it is not the complete solution. The interaction between the molten polymer and the steel surface is a complex process. Understanding the principles of Tribology11 helps us see that friction and abrasion are interconnected forces that cause mold degradation.

Advanced Protection: Coatings and Maintenance

For maximum longevity, especially in demanding applications, we must look beyond the base steel. Protective coatings create a barrier that significantly reduces the direct abrasive impact of the glass fibers found in STAMAX 30YM240.

The Role of Surface Coatings

Diamond-Like Carbon (DLC) or Titanium Nitride (TiN) coatings create an extremely hard, low-friction surface on the mold. This layer, often only a few microns thick, dramatically reduces the rate of abrasive wear, protecting the underlying steel and preserving fine details in the part.

Proactive Maintenance is Key

Even with the best steel and coatings, a proactive maintenance plan is non-negotiable for prolonging tool life. Regular inspection and cleaning of high-wear zones, such as the gate area, are crucial. This allows for early detection of wear before it impacts part dimensions or surface finish.

Effectively managing tool wear from glass-filled materials requires a multi-faceted approach. Combining hardened steels, advanced surface coatings like DLC, and a rigorous maintenance schedule is the most reliable strategy to ensure long-term production stability and protect your investment.

Get Your STAMAX 30YM240 Mold Trial Material Fast With MTM

Ready to Mold With STAMAX 30YM240? Eliminate waiting, logistics delays, and material uncertainty—send us your inquiry now for original or equivalent STAMAX 30YM240 delivered directly in China. Accelerate your mold trial process and keep your project on schedule with MTM’s pre-stocked solutions!

-

Learn how this property affects part strength and performance based on flow direction. ↩

-

This value helps predict material stiffness, which is crucial for designing rigid structural components. ↩

-

Understand how this property affects material deformation under stress, crucial for designing durable parts. ↩

-

Understanding creep resistance helps predict a component’s long-term dimensional stability under continuous load. ↩

-

Understanding this concept helps predict material flow and optimize your injection molding process. ↩

-

Understanding this helps optimize melt flow and prevent material defects. ↩

-

Understanding this property helps clarify why drying focuses on surface moisture, not internal absorption. ↩

-

Understanding this concept helps diagnose and solve part warpage issues in fiber-reinforced plastics. ↩

-

Understanding this helps optimize packing profiles for uniform density and dimensional control. ↩

-

Understanding marring helps in designing durable surfaces and selecting appropriate protective measures for high-wear applications. ↩

-

Understanding this field helps predict and prevent material wear, crucial for long-term mold performance and cost savings. ↩