Finding the right PC/ABS blend for your project shouldn’t mean waiting weeks for material shipments or compromising on authenticity. Many engineers face delays when sourcing genuine Cycoloy grades in China, often settling for questionable alternatives that can derail entire production schedules.

Cycoloy is SABIC’s premium PC/ABS blend family that combines polycarbonate’s heat resistance with ABS’s processability, offering engineers superior impact strength and dimensional stability for demanding automotive, electronics, and industrial applications.

This guide walks you through the complete Cycoloy ecosystem – from understanding grade differences like C1200 HF versus C2950, to solving common molding challenges like splay marks and warpage. I’ll also share how sourcing authentic material locally in China can streamline your prototyping timeline without the typical import headaches.

Balancing High Heat and Impact: Why Engineers Specify Cycoloy

Engineers often face a tough choice: select a material for high heat resistance or for high impact strength. Getting both is a challenge. This is where Cycoloy, a blend of Polycarbonate (PC) and Acrylonitrile Butadiene Styrene (ABS), becomes a go-to solution for demanding applications.

The Best of Both Worlds

Cycoloy resin combines the heat resistance and rigidity of PC with the excellent processability and ductility of ABS. This synergy creates a thermoplastic that excels where single materials might fail. It provides a balanced profile that is hard to achieve otherwise.

Key Property Comparison

Here’s a simplified look at how Cycoloy stacks up against its parent polymers based on our internal testing.

| Material | Heat Resistance | Impact Strength | Processability |

|---|---|---|---|

| PC (Polycarbonate) | High | Very High | Fair |

| ABS | Medium | High | Excellent |

| Cycoloy (PC/ABS) | High | Very High | Good |

This blend offers a versatile and reliable option for complex engineering parts.

When specifying Cycoloy, the real work lies in understanding the nuances of different grades. The ratio of PC to ABS directly influences the final properties. More PC generally means higher heat deflection temperatures but can sometimes compromise low-temperature impact performance.

Navigating the Performance Trade-offs

A critical factor is the application’s operating environment. For instance, a part exposed to high engine bay temperatures requires a high-PC grade. Conversely, a consumer electronic housing that must survive drops needs a grade optimized for impact strength, which might have more ABS. It is a constant balancing act.

Grade Selection Considerations

We often guide clients through this decision by focusing on the most critical failure mode. Is a sudden impact more likely than gradual heat distortion? This helps clarify which property to prioritize. The ductile-brittle transition1 temperature is a key data point we analyze, as it determines how the material behaves in the cold.

| Cycoloy Grade Type | Primary Advantage | Common Application |

|---|---|---|

| High Heat | Higher HDT | Automotive interior parts |

| High Impact | Superior toughness | Electronic enclosures |

| General Purpose | Balanced properties | Consumer appliances |

Choosing the right Cycoloy grade ensures the final product meets its functional requirements without over-engineering. At MTM, we stock various grades in China to help you quickly validate the best fit during mold trials.

Cycoloy resin effectively merges the heat resistance of PC with the impact strength and processability of ABS. Success depends on selecting the right grade by carefully balancing these inherent property trade-offs to meet specific application demands.

When clients approach me about Cycoloy, the vast portfolio can seem overwhelming. I simplify it by breaking it down into three main categories. This approach helps project managers quickly identify the right family of materials for their needs, preventing delays in sourcing for mold trials.

General Purpose Grades

These are the workhorses of the Cycoloy family. They offer a balanced profile of properties, making them suitable for a wide range of applications. Think automotive interiors or consumer electronics housings where a good mix of toughness and processability is key.

Specialized Resin Families

Beyond the standard grades, you’ll find specialized resins. These include flame retardant (FR) and medical grades, engineered for specific regulatory and performance requirements. Selecting the right one from the start is critical for project success.

The main distinction within the Sabic Cycoloy portfolio comes down to application-specific needs. While general purpose grades are versatile, they won’t pass certain safety or biocompatibility tests. This is where specialized grades become essential. My job at MTM is to ensure clients get the right material for their trials in China.

Flame Retardant (FR) Grades

For electronics or components near heat sources, flame retardant PC/ABS is non-negotiable. These Cycoloy resin grades contain additives to meet standards like UL94. Choosing an FR grade isn’t just about safety; it’s about market access for the final product.

Medical Grade Resins

Medical devices demand stringent biocompatibility and chemical resistance. Medical grade resin options in the Cycoloy portfolio are tested for these properties. They often have a higher cost but are required for applications involving patient contact. Understanding the Glass transition temperature2 is also crucial here for sterilization processes.

The table below offers a high-level comparison based on our work with these materials.

| Grade Category | Key Characteristic | Typical Application |

|---|---|---|

| General Purpose | Balanced impact & flow | Automotive trim, consumer goods |

| Flame Retardant | Meets UL94 ratings | Electronics housings, chargers |

| Medical Grade | Biocompatible, chemical resistant | Medical device housings, parts |

Understanding the fundamental differences between general-purpose, flame-retardant, and medical Cycoloy grades is the first step. This clarity streamlines the material selection for your mold trial, ensuring your project starts with the correct specifications and avoids costly rework.

Deep Dive: Cycoloy C1200 HF vs. C2950 – Choosing the Right Grade

Choosing the right Cycoloy grade is crucial for project success. Two popular options, C1200 HF and C2950, serve very different purposes. Misunderstanding their core properties can lead to molding issues or non-compliant parts. One is designed for flow, the other for safety.

High Flow vs. Flame Retardancy

The primary difference lies in their formulation. C1200 HF is optimized for easy processing, especially in complex molds. In contrast, C2950 contains additives to meet strict fire safety standards, which can affect its melt behavior.

Initial Comparison

This table offers a quick overview of their main characteristics.

| Feature | Cycoloy C1200 HF | Cycoloy C2950 |

|---|---|---|

| Primary Attribute | High Flow (HF) | Flame Retardant (FR) |

| Ideal Use Case | Thin-walled parts | Electronic housings |

| Key Advantage | Excellent processability | Safety compliance (UL94) |

Selecting the correct material early on saves significant time and cost, a lesson I’ve seen play out many times in mold trials.

Let’s break down the technical data. When my team consults with engineers, we focus on a few key metrics that directly impact performance and manufacturability. The choice between Cycoloy C1200 HF and C2950 becomes clear when you examine their specific properties.

Performance Under Pressure

C1200 HF is a workhorse for intricate designs. Its high Melt Volume Rate3 allows the resin to fill complex geometries and thin sections without requiring excessive injection pressure. This reduces stress on the mold and the part itself, minimizing warpage.

On the other hand, C2950 is the go-to for applications demanding safety compliance, like power adapters or internal device components. Its flame-retardant package ensures it meets UL94 V-0 standards. However, these additives typically reduce flowability compared to a non-FR grade.

Key Property Showdown

Based on our internal data comparisons, here is a more detailed look at their performance metrics.

| Property (Typical Values) | Cycoloy C1200 HF | Cycoloy C2950 |

|---|---|---|

| Melt Volume Rate (260°C/5kg) | ~24 cm³/10min | ~12 cm³/10min |

| Heat Deflection Temp (1.8 MPa) | ~110 °C | ~100 °C |

| Flame Rating (1.5 mm) | HB | V-0 |

| Notched Izod Impact (23°C) | ~55 kJ/m² | ~45 kJ/m² |

At MTM, we stock both grades in China. This ensures that if you are developing a product and need to trial both a high-flow and an FR-rated material, you can do so without waiting for overseas shipments.

The right choice comes down to your application’s primary requirement. For intricate, thin-walled parts where safety regulations are less stringent, C1200 HF is ideal. For any electronic or consumer device requiring a UL flame rating, C2950 is the necessary and responsible choice.

Designing for Manufacturability (DFM) with Cycoloy Resins

When working with a versatile material like Cycoloy PC/ABS, applying Design for Manufacturability (DFM) principles is crucial. Getting the design right from the start prevents costly mold revisions and production delays. This is a common challenge I see with teams preparing for mold trials in China.

Key DFM Focus Areas

Proper DFM for PC/ABS blends ensures parts are robust and aesthetically pleasing. The main goals are to avoid common molding defects like sink marks, voids, and warpage. Focusing on core geometry rules is the first step toward successful production and mold design optimization.

Common Design Pitfalls

Many issues stem from simple design oversights. Forgetting to account for the material’s specific shrinkage and flow behavior often leads to problems that are difficult to fix later. Here is a quick overview of what to watch for.

| Design Element | Primary Concern | Recommended Action |

|---|---|---|

| Wall Thickness | Voids, Sink Marks | Maintain uniformity |

| Ribs | Sink Marks, Stress | Limit thickness to 50-60% of wall |

| Bosses | Cracking, Voids | Add gussets for reinforcement |

DFM for PC/ABS blends like Cycoloy is all about controlling the material flow and cooling process through smart geometry. At MTM, we often advise clients to pay close attention to these details before we supply the material for their mold trials, saving them time and resources.

Wall Thickness Recommendations

Maintaining a uniform wall thickness is the most important rule in plastic part design guidelines. For Cycoloy resins, we recommend a nominal wall thickness between 1.5mm and 3.0mm. Abrupt changes in thickness create uneven cooling rates, which leads to warpage and internal stress.

Rib and Boss Design Rules

Ribs and bosses are essential for strength but can cause cosmetic defects if designed improperly. A rib’s thickness should never exceed 60% of the wall it is attached to. This simple rule minimizes sink marks on the opposite surface. The material’s tendency for Anisotropic shrinkage4 can also be managed with correct rib placement.

To reinforce bosses and prevent cracking under load, gussets are highly effective. Below are some practical guidelines our clients have found useful.

| Feature | Guideline | Rationale |

|---|---|---|

| Rib Thickness | 50-60% of Nominal Wall | Prevents sink marks |

| Rib Height | < 3x Nominal Wall | Ensures proper filling |

| Boss Outer Diameter | 2x Inner Diameter | Provides structural integrity |

| Gussets | Connect boss to floor/wall | Adds strength, prevents stress |

Proper DFM for Cycoloy resins, focusing on uniform wall thickness and correct rib and boss design, is essential. These guidelines help prevent common molding defects like sink marks and voids, ensuring a smoother transition from design to successful manufacturing.

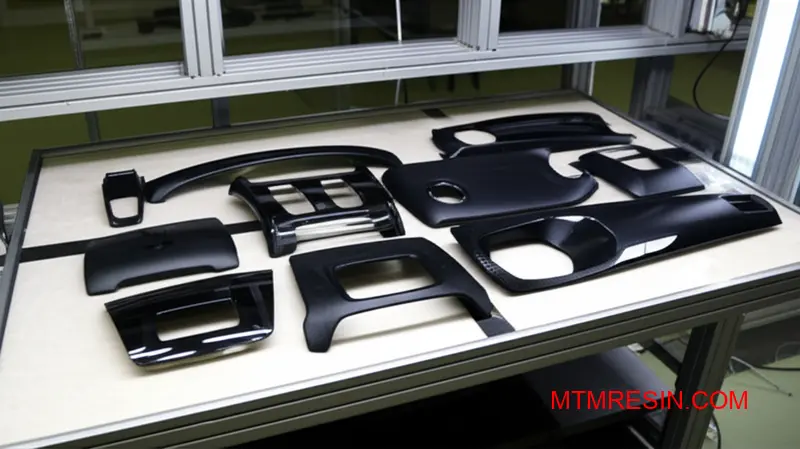

Understanding Chemical Resistance in Automotive Interiors

Automotive interiors are constantly exposed to a wide range of chemicals. From hand sanitizers and lotions to aggressive cleaning products, the plastics used must endure these encounters without degrading. This resistance is not just about aesthetics; it is fundamental to the part’s long-term structural integrity.

Common Chemical Exposures

Many materials can show signs of failure, such as discoloration or small cracks, when exposed to everyday substances. This degradation often happens slowly over time, making it a critical consideration during the material selection phase for any interior component.

| Chemical Source | Common Agents |

|---|---|

| Personal Care | Sunscreen, Hand Lotion, Insect Repellent |

| Cleaning Agents | Glass Cleaner, All-Purpose Wipes, Vinyl Protectants |

| Food & Drink | Oils, Sugars, Acids |

The Importance of Material Choice

Selecting the correct material from the outset is crucial. For parts requiring a balance of impact strength and chemical resilience, a PC/ABS blend like Cycoloy is often specified. However, the specific grade chosen makes all the difference in performance.

The Challenge with Standard PC/ABS

While PC/ABS blends like Cycoloy offer an excellent balance of properties, the polycarbonate (PC) component can be vulnerable to certain chemical agents. Greases, oils, and specific cleaning solvents can attack the polymer chains, leading to a failure mode known as Environmental Stress Cracking5.

This phenomenon occurs when a plastic part is under internal or external stress and is exposed to a chemical agent. The combination can cause premature brittle failure at stress levels far below what the material would normally withstand. This is a significant reliability concern in automotive interiors.

Selecting the Right Cycoloy Grade for ESCR

To address this, material suppliers have developed specialized grades with enhanced chemical resistance. Within the Cycoloy family, specific formulations are engineered to meet stringent automotive ESCR (Environmental Stress Cracking Resistance) standards. These grades undergo rigorous testing against a list of specified chemicals required by OEMs.

Matching the Grade to the Standard

Choosing the right grade is not a one-size-fits-all process. We must match the material’s performance data with the OEM’s unique testing protocol. A Cycoloy grade that passes one manufacturer’s requirements may not meet another’s. At MTM, we help clients select the precise grade that ensures compliance.

| Property | Standard PC/ABS | High-ESCR Cycoloy Grade |

|---|---|---|

| Resistance to Sunscreen | Moderate | High |

| Resistance to Cleaners | Low to Moderate | High |

| ESCR Test Result (OEM Spec) | Fail | Pass |

Choosing the right material is vital for automotive interiors. While PC/ABS like Cycoloy is a strong option, its chemical resistance is key. Selecting a specific grade engineered for high ESCR is essential to prevent stress cracking and meet OEM standards.

Mold Temperature Control: Balancing Cycle Time and Gloss

Finding the right mold temperature for Cycoloy is a classic balancing act. You want a high-gloss finish, but you also need to meet cycle time targets. Increasing the temperature often improves the surface appearance but extends the cooling phase, directly impacting production efficiency.

The Gloss vs. Speed Dilemma

A hotter mold allows the molten polymer to replicate the cavity surface more accurately, resulting in a higher gloss. However, this means the part takes longer to cool and solidify before it can be ejected. This trade-off is a constant challenge in injection molding.

Temperature Impact Overview

Based on our tests with clients, the relationship is quite direct. Below is a simplified breakdown of the effects of mold temperature on key outcomes for materials like Cycoloy.

| Mold Temperature | Surface Gloss | Cycle Time |

|---|---|---|

| Low (e.g., 50°C) | Lower | Faster |

| High (e.g., 90°C) | Higher | Slower |

Optimizing for Cycoloy PC/ABS Blends

When working with PC/ABS blends like Cycoloy, the mold temperature is critical for aesthetic control. The PC component benefits from higher temperatures for better flow and surface replication, while the ABS provides toughness. A low mold temperature can freeze the material too quickly, creating flow lines and a dull finish.

Recommended Temperature Ranges

For high-gloss applications, I typically start with a mold temperature between 80°C and 95°C. This range allows the polymer chains to align properly against the mold surface before solidifying. The molecular arrangement, influenced by Crystallinity6, plays a significant role here. While PC/ABS is amorphous, the principle of polymer relaxation for better surface quality still applies.

If cycle time is the primary driver, you might lower the temperature to the 60°C to 75°C range. However, be prepared for a potential reduction in gloss. At MTM, we ensure clients have the precise Cycoloy grade so these process adjustments yield predictable results.

| Goal | Recommended Mold Temp (°C) | Expected Outcome |

|---|---|---|

| High Gloss & Aesthetics | 80 – 95 | Excellent surface finish, but longer cycle time. |

| Balanced Performance | 70 – 85 | Good gloss with a moderate cycle time. |

| Cycle Time Reduction | 60 – 75 | Fastest cycle, potential for lower gloss. |

Achieving the right balance for Cycoloy requires careful mold temperature control. This setting directly impacts both the part’s surface gloss and the overall production efficiency. Understanding these trade-offs is crucial for optimizing your molding process and achieving the desired part quality.

Troubleshooting Splay and Silver Streaks in Molded Parts

Splay marks, often seen as silver streaks, are a frequent challenge in injection molding, particularly with PC/ABS blends like Cycoloy. The key is to correctly identify the cause. These visual defects almost always stem from either trapped moisture or thermal degradation of the material.

Differentiating Moisture and Heat Splay

Distinguishing between the two is the first step in effective splay marks injection molding troubleshooting. Moisture splay appears as silvery streaks radiating from the gate, while heat-induced splay often looks more like random, darker burns or gas marks on the part surface.

Visual Cues for Diagnosis

A simple table can help quickly differentiate the cause based on visual inspection.

| Defect Type | Appearance | Common Location |

|---|---|---|

| Moisture Splay | Bright, silvery streaks | Radiating from the gate |

| Heat Splay | Darker, brownish streaks or burns | Often near the end of fill |

To resolve these visual defects in Cycoloy parts, a systematic approach is necessary. Don’t just tweak parameters randomly. Understanding the root cause—be it moisture or heat—guides every adjustment and leads to a more stable and efficient plastic processing solution.

Root Cause Analysis and Adjustments

Moisture is the most common culprit. Materials like PC/ABS are hygroscopic7, meaning they readily absorb moisture from the air. If not dried properly before processing, this trapped water turns to steam in the hot barrel, causing splay. This is a constant issue we help clients avoid by ensuring materials from MTM are properly handled.

Heat-Related Splay Marks

Heat splay occurs when the material degrades due to excessive temperature or prolonged residence time in the barrel. This breaks down the polymer chains, releasing gases that create streaks. This is a frequent issue with temperature-sensitive materials if process settings are not optimized.

Parameter Adjustment Guide

For immediate silver streaks troubleshooting, consider these adjustments. After working with our clients, we’ve found these starting points to be highly effective.

| Splay Type | Primary Cause | Recommended Action |

|---|---|---|

| Moisture Splay | Inadequate Drying | Verify dryer temp & time; increase if needed |

| Heat Splay | Excessive Melt Temp | Lower barrel temperatures systematically |

| Heat Splay | Long Residence Time | Reduce cycle time or use a smaller shot size |

Correctly identifying the root cause of splay is critical. Whether it’s improper material drying or excessive processing heat, a targeted adjustment to your parameters is the only way to achieve a stable, repeatable solution for producing high-quality parts.

Controlling Warpage and Shrinkage in Complex Geometries

PC/ABS blends like Cycoloy present unique challenges due to differential shrinkage. The polycarbonate and ABS components cool and shrink at different rates, creating internal stress. This effect is magnified in large, flat housings or parts with complex features, often leading to unacceptable warpage.

The Challenge with Blends

The core issue with a PC/ABS blend is the inherent conflict between the two polymers’ thermal properties. This inconsistency makes achieving tight dimensional tolerances difficult. It requires precise control over both the material and the molding process to ensure stability.

Key Factors in PC/ABS Warpage

| Factor | Description | Impact on Warpage |

|---|---|---|

| Material Composition | The specific ratio of PC to ABS in the blend. | High |

| Part Geometry | Wall thickness variations and large, unsupported areas. | High |

| Processing | Melt temperature, mold temperature, and packing. | High |

Controlling these factors is essential for producing dimensionally stable parts.

Strategic Gate Location

For large or complex parts, gate placement is the first line of defense in warpage control plastic. Multiple gates can help distribute pressure evenly, promoting uniform filling and cooling. Avoid placing gates on thin sections that freeze off too early, as this cuts off the ability to pack out the part effectively.

Mastering Packing Pressure

Once the cavity is filled, the packing phase is crucial for dimension stability. A properly set packing pressure and time forces additional material into the mold to compensate for shrinkage as the part cools. This directly counteracts the material’s tendency to pull away from the mold walls unevenly.

Process Optimization for Flatness

| Parameter | Recommended Adjustment | Reason for Change |

|---|---|---|

| Packing Pressure | Increase incrementally | Fills out the part as it shrinks, reducing voids. |

| Packing Time | Extend until gate freeze-off | Ensures pressure is applied throughout the critical cooling phase. |

| Mold Temperature | Maintain uniformity | Minimizes temperature differences that cause uneven shrinkage. |

Poorly managed cooling and packing can lead to high levels of Residual Stress8, the primary driver of delayed warpage. Using a consistent material batch, like the Cycoloy we supply at MTM, ensures that your process adjustments yield predictable results without material variability clouding the outcome.

Effectively controlling warpage in PC/ABS requires a systematic approach. Strategic gate location combined with optimized packing pressure is key. A consistent, high-quality material like Cycoloy provides the stable foundation needed for achieving precise injection molding flatness and dimension stability.

Gate Design and Positioning for Structural Integrity

When working with Cycoloy, a common PC/ABS blend, we cannot simply reuse standard ABS gating strategies. The material’s higher viscosity and sensitivity to shear demand a more thoughtful approach. Proper gate design is crucial not just for aesthetics but for the part’s long-term structural integrity.

Key Differences in Gating

Positioning the gate correctly minimizes internal stress and prevents cosmetic flaws. This is a critical step during the mold trial phase. At MTM, we ensure our clients have the right grade of Cycoloy resin ready to validate these tooling decisions.

| Parameter | Standard ABS | Cycoloy (PC/ABS) |

|---|---|---|

| Melt Viscosity | Lower | Higher |

| Shear Sensitivity | Moderate | Higher |

| Weld Line Strength | Generally good | Can be weaker |

| Processing Window | Wider | Narrower |

Initial Placement Strategy

The primary goal is to fill the cavity uniformly while reducing pressure. Placing gates in thick-walled sections helps achieve this. This ensures proper packing and minimizes the risk of sink marks or voids, which compromise the part’s strength.

The polycarbonate component in Cycoloy is the main reason for its distinct behavior. It increases melt viscosity, which means the material flows more slowly and requires higher injection pressure. This can lead to significant molded-in stress if the gate location is not optimized.

Strategies for Stress Reduction

A primary strategy is to gate into the thickest section of the part. This allows the material to flow from thick to thin, ensuring the part is fully packed out before the gate freezes. This practice directly fights against warpage and internal stresses. You can often see these stress patterns using polarized light, a phenomenon known as birefringence9.

Hiding Gate Vestiges

For aesthetic parts, gate location is a balance between structural needs and visual appeal. We often recommend placing gates on non-critical or hidden surfaces. This approach contains any cosmetic blemishes from gate removal, ensuring the final product looks clean.

| Gate Type | Best Use Case for Cycoloy | Primary Benefit |

|---|---|---|

| Tab Gate | Large, flat parts | Reduces shear stress at entry point. |

| Fan Gate | Thin, wide parts | Promotes even flow front progression. |

| Tunnel Gate | Automated processes | Automatically separates part from runner. |

Optimizing gate design for Cycoloy is essential for minimizing internal stress and hiding vestiges. Placing gates in thick, non-cosmetic areas is a key strategy that improves both structural integrity and appearance, a crucial step validated during the mold trial process.

Secondary Operations: Painting and Plating Cycoloy Surfaces

Achieving a flawless finish on Cycoloy parts starts with material selection. Painting and electroplating are common finishing steps, but they demand different surface properties for optimal adhesion. Choosing the right grade of this PC/ABS blend is crucial to prevent costly failures like peeling or blistering.

Considerations for Painting

For painting applications, the key is ensuring the paint adheres strongly to the plastic surface. Some Cycoloy grades are formulated for better paint compatibility, often reducing the need for aggressive primers. This simplifies the production process and lowers overall costs.

Success in Electroplating

Electroplating plastic is more complex. It requires a grade that allows for proper chemical etching, a step that creates microscopic pits for the metal layers to grip onto. The ABS component in Cycoloy is essential for this process to succeed.

| Finishing Process | Key Challenge | Recommended Approach |

|---|---|---|

| Painting | Adhesion Failure | Select a grade with high surface receptivity. |

| Electroplating | Incomplete Etching | Use a plating-specific grade like Cycoloy MC series. |

When we delve deeper, the success of secondary operations on Cycoloy hinges on its composition. The ratio of polycarbonate (PC) to acrylonitrile butadiene styrene (ABS) significantly impacts surface characteristics. A higher ABS content generally improves the electroplating process.

The Role of ABS in Plating

During electroplating, the butadiene particles in the ABS are chemically etched away from the surface. This creates a microporous structure that provides a strong mechanical anchor for the initial electroless nickel or copper layer. If the grade is not designed for plating, this etching process will be ineffective.

Surface Preparation and Adhesion

For both painting and plating, surface cleanliness is non-negotiable. However, the material’s inherent Surface Energy10 also plays a vital role. Lower surface energy can lead to poor wetting by paints or plating solutions, causing defects. At MTM, we often help clients select grades that balance mechanical properties with finishing requirements.

| Grade Series | Primary Application | Finishing Suitability |

|---|---|---|

| Cycoloy C Series | General Purpose | Good for painting |

| Cycoloy MC Series | Plating Grades | Excellent for electroplating |

| Cycoloy XCM Series | High Performance | Varies; requires testing |

Choosing the correct Cycoloy grade is fundamental for achieving high-quality painted or electroplated finishes. Understanding the material’s interaction with surface treatments prevents adhesion failure and ensures the final part meets aesthetic and functional specifications, saving time and resources during production.

Sourcing Strategy: Local Availability of Genuine Cycoloy in China

Finding genuine Sabic Cycoloy in China for mold trials can be a major hurdle. Delays from international shipping and customs clearance often derail project timelines. The primary concern is ensuring the material is authentic and consistent, which is crucial for accurate trial results.

The Local Stock Advantage

A reliable local supplier eliminates these risks. At MTM, we pre-stock genuine Cycoloy resin in China. This means you can buy Cycoloy in China and have it delivered quickly, avoiding international logistics entirely. This approach saves both time and significant shipping costs.

Ensuring Quality and Speed

Our model is built on providing verified, ready-to-use materials for your mold trials.

| Sourcing Method | Lead Time | Authenticity Risk |

|---|---|---|

| International Shipment | 4-6 Weeks | Low |

| Local Unverified Trader | 1-3 Days | High |

| MTM Pre-Stocked | 1-3 Days | Low (Verified) |

This streamlined process helps your project stay on schedule without compromising on material integrity.

When you need to buy Cycoloy in China, the biggest question is authenticity. A non-genuine material can invalidate an entire mold trial, leading to incorrect conclusions and costly rework. This is why a verifiable supply chain is not just a preference; it is a necessity for serious engineering projects.

Our Verification Process

As a genuine Sabic resin supplier, we have a strict verification protocol. Every batch of Cycoloy at our MTM resin stock facility is accompanied by its original Certificate of Analysis (COA). We cross-reference the COA data with Sabic’s official specifications to confirm its integrity.

| Verification Step | Purpose |

|---|---|

| COA Check | Confirms material grade, lot number, and properties. |

| Batch Traceability | Ensures lot-to-lot consistency for global OEMs. |

| Visual Inspection | Checks for correct packaging and labeling. |

The Importance of Lot Consistency

For global OEMs, consistency is key. Cycoloy, being a Polymer Blend11, derives its unique properties from a precise formulation. Different production lots can have minor variations. We manage our inventory to provide consistent batches, ensuring your trial results in China are comparable to those anywhere else in the world.

Sourcing genuine Cycoloy in China is simple with a reliable local partner. MTM’s pre-stocked inventory, verified with a material authenticity COA, eliminates shipping delays and ensures lot consistency. This helps you conduct accurate and timely mold trials without logistical headaches.

Choose MTM for Your Next Cycoloy PC/ABS Trial in China

Need authentic Cycoloy PC/ABS for mold trials or production in China? MTM has the genuine grades you require—pre-stocked and ready for immediate pickup, with COA guarantee and technical support. Send us your inquiry now for a fast, hassle-free quote and accelerate your project timeline!

-

Understanding this concept helps predict material failure in varying thermal conditions. ↩

-

This concept helps predict a polymer’s response to heat, which is critical for design and manufacturing choices. ↩

-

Understand how this key metric predicts processing behavior and influences final part quality. ↩

-

Understanding this concept helps predict material behavior and control part warpage during the cooling phase. ↩

-

Understanding this mechanism is key to preventing unexpected brittle failures in plastic component design. ↩

-

Understanding polymer chain alignment explains how temperature affects a part’s final mechanical and aesthetic properties. ↩

-

Understanding this property is key to preventing moisture-related defects in many engineering plastics. ↩

-

Understanding this concept is key to predicting and troubleshooting long-term part deformation and failure in molded components. ↩

-

Learn how this optical property visually reveals stress patterns, aiding in part design and failure analysis. ↩

-

Understanding this concept helps predict how well paints and coatings will bond to plastic surfaces. ↩

-

Understanding polymer blends helps appreciate how materials like Cycoloy achieve their unique combination of properties. ↩