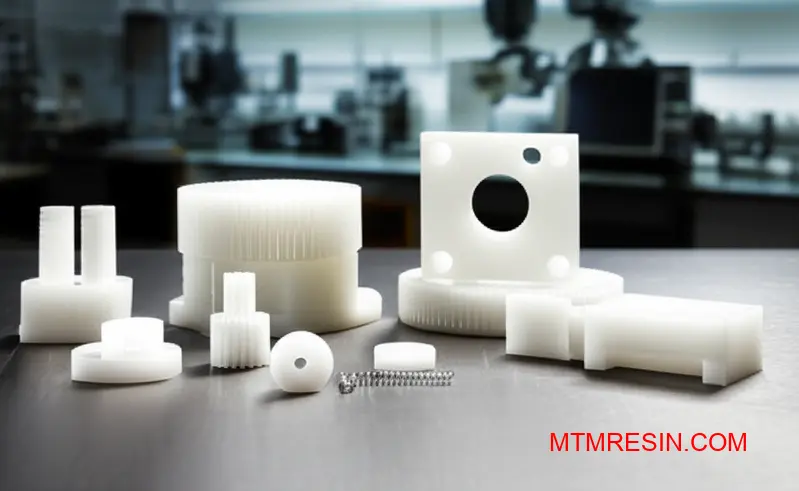

Product engineers often specify Delrin for demanding applications but then face material availability nightmares during China-based trials. When you need genuine DuPont Delrin for your mold testing, the wrong material substitute can derail your entire development timeline and compromise component performance.

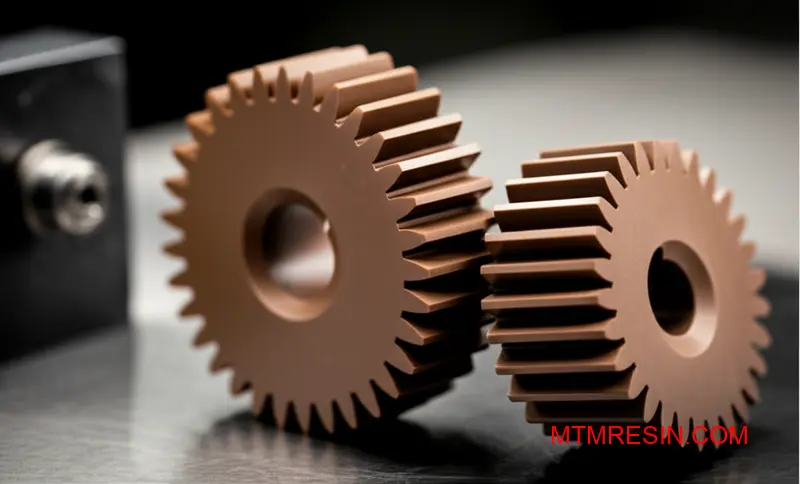

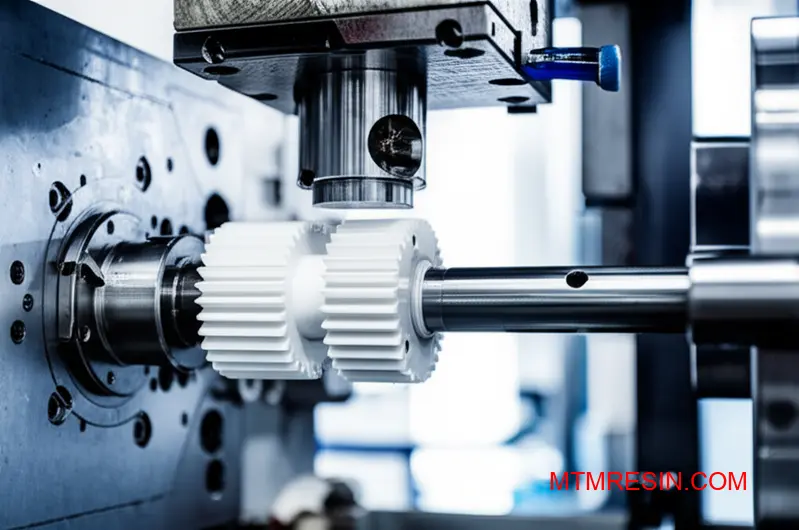

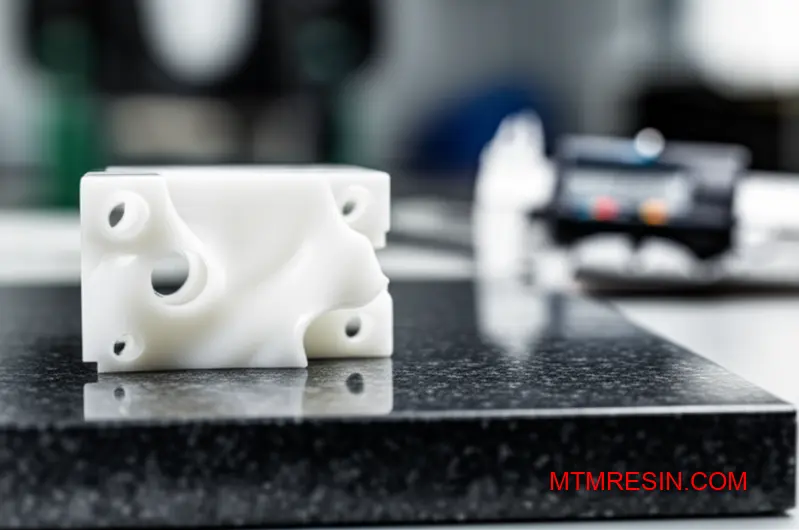

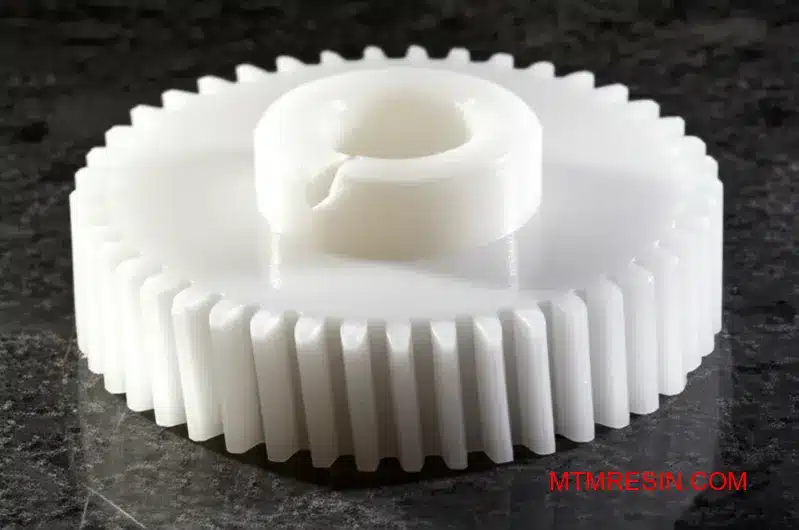

Delrin (POM-H) is DuPont’s premium acetal homopolymer known for superior stiffness, fatigue resistance, and dimensional stability compared to generic copolymers, making it essential for high-load mechanical components like gears, springs, and precision housings.

This guide breaks down everything you need to know about Delrin properties, grade selection, and processing requirements. I’ll share practical insights on avoiding common molding defects and securing authentic material for your China production trials.

Engineering Acetal: Why Choose Delrin for High-Load Applications

When engineers need a material for high-load mechanical parts, Delrin is often at the top of the list. It’s not just a plastic; it’s an engineering solution that frequently replaces metal. Its unique combination of properties makes it exceptionally reliable for gears, bearings, and structural components.

The Delrin Advantage

The primary reason for choosing Delrin is its performance under stress. It offers a balance of strength and stiffness that many other plastics cannot match. This makes it a go-to material for parts that must endure continuous mechanical strain without failure or deformation over time.

Key Performance Comparison

Here’s a quick look at how Delrin stacks up against a common alternative like Aluminum 6061 in key areas relevant to high-load applications.

| Property | Delrin (Acetal Homopolymer) | Aluminum 6061 |

|---|---|---|

| Tensile Strength | High | Very High |

| Stiffness (Flexural Modulus) | High | Very High |

| Fatigue Resistance | Excellent | Good |

| Corrosion Resistance | Excellent | Good |

This shows why Delrin is a viable and often superior choice, especially when factors like weight and cost are considered.

Deeper Dive into Delrin’s Properties

Delrin, an acetal homopolymer, has a highly ordered molecular structure. This structure is key to its exceptional mechanical properties. Unlike many plastics, it maintains its integrity under repeated cyclical loading, which is why its fatigue resistance is so valued in dynamic applications like conveyor systems.

The Role of Structure in Performance

The molecular makeup of Delrin directly contributes to its high degree of Crystallinity1. This attribute is what gives the material its impressive stiffness and strength. It prevents the polymer chains from easily moving past one another, resulting in a very hard and resilient material.

Acetal Homopolymer vs. Copolymer

When specifying acetal, it’s crucial to distinguish between the homopolymer (Delrin) and copolymer (POM-C) grades. Our tests with clients show clear differences.

| Feature | Delrin (POM-H) | Acetal Copolymer (POM-C) |

|---|---|---|

| Stiffness | Higher | Lower |

| Tensile Strength | Higher | Lower |

| Creep Resistance | Better | Good |

| Chemical Resistance | Good | Better (especially to hot water) |

For applications demanding the highest mechanical performance, Delrin is typically the better choice. We help clients at MTM select the right grade for their mold trials in China, ensuring the material meets precise engineering needs from the start.

Delrin’s selection for high-load applications is a strategic engineering decision. Its superior tensile strength, stiffness, and fatigue resistance make it a reliable metal replacement that delivers consistent performance under demanding conditions, justifying its role in critical components.

The Critical Difference: Delrin Homopolymer (POM-H) vs. Copolymer

When an engineering drawing specifies Delrin, it’s calling for a specific acetal homopolymer (POM-H). Yet, I often see procurement teams tempted to substitute it with a generic acetal copolymer (POM-C) to reduce costs. This is a critical mistake that can compromise the final part’s integrity.

Key Performance Distinctions

The molecular structures of POM-H and POM-C are fundamentally different. This directly impacts their performance characteristics. Delrin, as a homopolymer, generally offers superior mechanical properties compared to standard copolymers.

Homopolymer vs. Copolymer at a Glance

| Property | Delrin (POM-H) | Acetal Copolymer (POM-C) |

|---|---|---|

| Tensile Strength | Higher | Lower |

| Stiffness | Higher | Lower |

| Porosity Risk | Minimal | Higher |

This distinction is crucial for applications demanding high strength and long-term reliability.

Technical Breakdown: POM-H vs. POM-C

The differences go beyond basic datasheet values. In practical applications, these material distinctions become much more apparent and can determine the success or failure of a component, especially in high-performance scenarios.

The Problem with Centerline Porosity

Acetal copolymers often exhibit centerline porosity, which are tiny voids in the core of a molded part. While not always visible, this weakness can lead to premature failure under stress or chemical exposure. Delrin’s uniform, dense structure makes it far less susceptible to this issue.

Superior Mechanical Properties

Our tests consistently show Delrin has higher tensile strength, stiffness, and creep resistance. This makes it the only choice for parts like gears or bearings that face constant loads. Substituting with POM-C in such cases risks compromising the product’s Fatigue Life2 and overall durability.

| Technical Aspect | Delrin (POM-H) | Acetal Copolymer (POM-C) |

|---|---|---|

| Centerline Porosity | Very Low Risk | Common Issue |

| Tensile Strength | ~72 MPa | ~62 MPa |

| Flexural Modulus | ~2900 MPa | ~2600 MPa |

| Chemical Resistance | Good (alkalis) | Better (hot water) |

When clients in China need to validate a design specifying Delrin, we ensure they have the genuine material. Using an incorrect substitute during mold trials gives false performance data, leading to costly redesigns later.

In short, Delrin (POM-H) and acetal copolymers (POM-C) are not interchangeable. The superior mechanical strength and reduced porosity of Delrin are critical for demanding applications. Always use the material specified on the drawing to ensure accurate and reliable mold trial results.

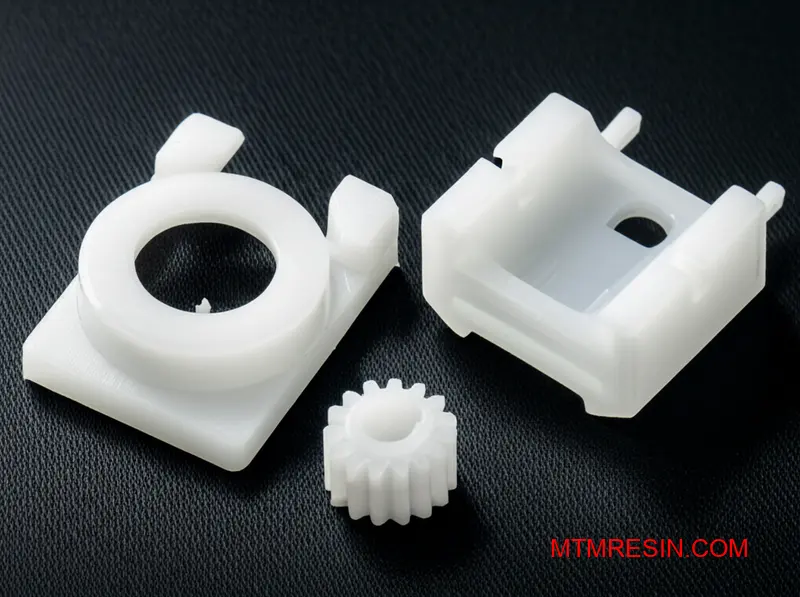

Decoding Delrin Grades: When to Select 100, 500, or 900 Series

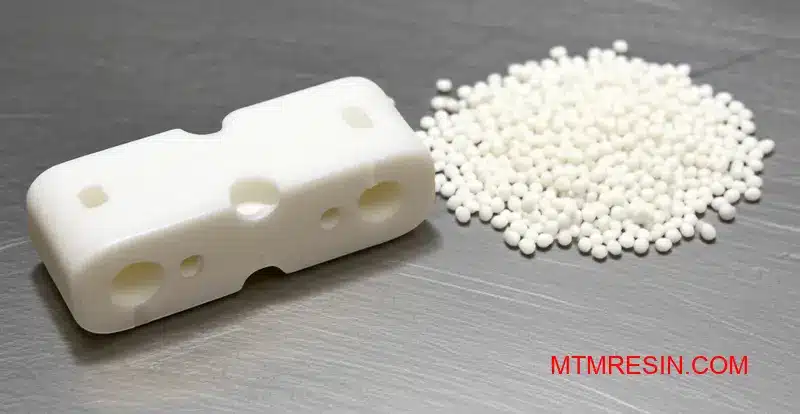

Choosing the right Delrin grade can feel overwhelming. The numbers—100, 500, 900—aren’t random. They primarily indicate viscosity, which directly impacts how the material processes and performs. Getting this choice right from the start is crucial for a successful mold trial.

Key Delrin Series Overview

Understanding the fundamental differences is the first step. High viscosity often correlates with higher mechanical strength, while low viscosity allows for better flow into complex, thin-walled parts. This balance is key.

Initial Comparison

| Grade Series | Primary Characteristic | Best For |

|---|---|---|

| Delrin 100 | High Viscosity, Max Toughness | Stock shapes, thick-walled parts |

| Delrin 500 | Medium Viscosity, General Purpose | Balanced performance, most moldings |

| Delrin 900 | Low Viscosity, High Flow | Thin-walled, complex geometries |

Understanding the naming convention is straightforward once you grasp the core principle: the series number is a direct guide to its melt viscosity. This single property influences everything from processing parameters to the final part’s toughness and fatigue resistance. Let’s break down this classification.

Viscosity and Application Fit

The main difference between Delrin 100, 500, and 900 series is their molecular weight, which determines viscosity. A higher number doesn’t mean "better"; it means different flow characteristics for specific applications. At MTM, we guide clients on this selection daily for their mold trials in China.

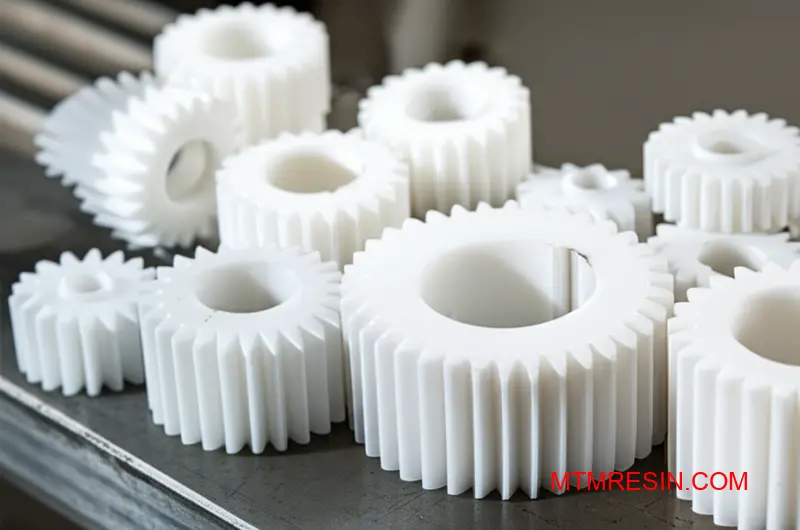

Delrin 100 Series: The Workhorse for Strength

This is the highest viscosity grade. Its high molecular weight gives it superior toughness, impact strength, and creep resistance. It is ideal for robust mechanical parts but can be challenging to mold into thin or intricate shapes. Think heavy-duty gears or conveyor belt components.

Delrin 500 Series: The All-Rounder

As the medium-viscosity option, the 500 series is the most common for general-purpose injection molding. It offers a great balance between mechanical properties and ease of processing. When clients are unsure, this is often the starting point for a wide range of applications.

Delrin 900 Series: The Specialist for Detail

This low-viscosity, high-flow grade is designed for parts with thin walls and complex details. The lower viscosity allows the material to fill the mold cavity quickly and completely. This results in faster cycle times but slightly reduced toughness compared to the Delrin 100 series. A key metric here is the Melt Flow Rate3.

| Feature | Delrin 100 | Delrin 500 | Delrin 900 |

|---|---|---|---|

| Viscosity | High | Medium | Low |

| Toughness | Highest | High | Good |

| Mold Flow | Low | Medium | High |

| Typical Use | Bearings, Rollers | Buckles, Fasteners | Small Gears, Clips |

Selecting the right Delrin grade—100 for maximum toughness, 500 for balanced properties, or 900 for high flow—is critical. Your choice directly affects processability and final part performance. Understanding viscosity is the first step to making an informed decision for your project.

Deep Dive into Delrin 100: Superior Toughness and Fatigue Life

When engineers need a material that refuses to quit, the Delrin 100 series is often the top choice. Its reputation for superior toughness and exceptional fatigue life is well-earned. This material excels in applications where parts face repeated stress and impact over long periods.

Why It Stands Out

Delrin 100 is not just another acetal. Its unique properties make it a reliable performer in demanding mechanical components. It provides strength and stiffness while resisting wear and abrasion, making it a go-to for parts that must endure harsh conditions without failure.

Core Performance Attributes

We see it specified for parts needing long-term reliability. Below are key Delrin 100 properties.

| Property | Benefit |

|---|---|

| High Impact Strength | Resists fracture from sudden loads |

| Excellent Fatigue Life | Withstands cyclical stress without failure |

| Low Friction | Ensures smooth operation in moving parts |

| Chemical Resistance | Stable against many solvents and fuels |

This combination makes it a valuable material for critical applications.

The secret to Delrin 100’s performance lies in its molecular structure. Specifically, grades like Delrin 100P feature a high viscosity. This indicates longer polymer chains, which are more entangled and create a stronger, more resilient material that resists deformation under load.

Viscosity and Application Suitability

This high viscosity is crucial for components like gears and springs. Lower viscosity acetals might process faster but they simply cannot match the long-term durability needed for these parts. The molecular structure of Polyoxymethylene4 in the Delrin 100 series is engineered for maximum toughness.

At MTM, we often supply Delrin 100P to clients in China who are trialing molds for automotive or industrial parts. They need to validate that their designs can withstand real-world stress. Using the correct high-viscosity grade from the start prevents costly failures later.

Performance in Gear Applications

After reviewing data from our clients’ tests, we’ve noted key performance differences. High viscosity directly improves gear life.

| Feature | Delrin 100P (High Viscosity) | Standard Acetal (Low Viscosity) |

|---|---|---|

| Wear Resistance | Excellent | Good |

| Load-Bearing Capacity | High | Moderate |

| Fatigue Endurance | Superior | Standard |

| Creep Resistance | Excellent | Good |

These attributes ensure gears made from Delrin 100 last longer.

Delrin 100’s high viscosity and robust molecular structure provide unmatched toughness and fatigue life. This makes it the ideal choice for high-stress mechanical parts like gears and springs, ensuring reliability where failure is not an option.

Delrin 500 Series Analysis: The General Purpose Standard

The Delrin 500 series, particularly 500P, is the industry’s go-to general-purpose acetal. Its popularity comes from a highly balanced set of properties. This makes it a reliable choice for a vast range of injection molding applications without needing special modifications.

An Unbeatable Baseline

Engineers frequently select Delrin 500P for its predictable performance and processing stability. It offers an excellent combination of mechanical strength, stiffness, and dimensional stability. This reliability simplifies the material selection process for many projects.

Key Specifications

Based on our client trials, the material consistently delivers on its core promises. Its properties provide a solid foundation for durable components.

| Property | Delrin 500P | Unit |

|---|---|---|

| Melt Flow Rate (190°C/2.16 kg) | 15 | g/10 min |

| Tensile Strength, Yield | 69 | MPa |

| Flexural Modulus | 2800 | MPa |

| Izod Impact, Notched | 75 | J/m |

The Importance of Medium Viscosity

The defining feature of Delrin 500P is its medium viscosity. This characteristic offers a wide processing window, making it forgiving for molders. It flows easily enough for general parts but is not so fluid that it causes excessive flash or weak weld lines.

Processing and Part Integrity

This balance is fundamental to material Rheology5. Proper flow behavior is critical for filling the mold uniformly, which directly affects the final part’s strength and appearance. Poor flow can lead to cosmetic defects or structural failures under stress. At MTM, we stock Delrin for trials because its behavior is so well-understood.

When to Choose Delrin 500P

This grade is ideal for parts that don’t have extremely thin walls or exceptionally long flow paths. For those applications, a higher-flow material might be better. However, for most components like gears, clips, and housings, its properties are perfect.

| Application Type | Recommended Flow | Why |

|---|---|---|

| Standard Gears & Bushings | Medium (500P) | Best balance of wear and strength. |

| Thin-Walled Electronics | High | Needed to fill small, intricate features. |

| Thick Structural Parts | Low | Maximizes strength and impact resistance. |

The Delrin 500 series is a benchmark for general-purpose acetal due to its balanced properties. Its medium viscosity provides a wide processing window, while its mechanical strength ensures reliable performance for a huge variety of molded parts.

Low Friction Solutions: Utilizing Delrin AF and PTFE Blends

When standard acetal isn’t enough, specialty grades come into play. Materials like Delrin AF blends integrate PTFE fibers directly into the POM matrix. This creates a composite with an exceptionally low coefficient of friction.

Engineered for Wear Resistance

These materials are designed for moving parts that experience constant contact. Wear strips and bearings made from a PTFE-filled POM offer self-lubricating properties. This reduces maintenance needs and extends the life of the component significantly.

Performance Comparison

Below is a simple breakdown of how these materials compare based on our internal testing.

| Feature | Standard Acetal (POM) | Delrin AF Blend (POM+PTFE) |

|---|---|---|

| Coefficient of Friction | Moderate | Extremely Low |

| Wear Rate | Standard | Significantly Reduced |

| Self-Lubrication | No | Yes |

| Stick-Slip | Possible | Eliminated |

When evaluating a low-friction acetal, it’s about more than just a single specification. The goal is predictable, long-term performance. A Delrin AF blend provides this by creating a material that lubricates itself under load.

How Self-Lubrication Works

During operation, the PTFE fibers within the polymer matrix migrate to the surface. This transfer creates a thin, durable lubricating film between the moving parts. It is a core principle in the field of tribology6, ensuring smooth motion without external lubricants.

Choosing the Right Blend

Not all PTFE-filled POM materials are identical. The percentage of PTFE filler dramatically influences the final properties. Selecting the correct grade is crucial. At MTM, we help clients source the precise material needed for their mold trials, ensuring the final part meets design specifications for wear resistance.

| Application Example | Common PTFE % | Primary Benefit |

|---|---|---|

| High-Speed Bushings | 15-20% | Low Heat Generation |

| Conveyor Wear Strips | 10-15% | High Durability |

| Precision Gears | 5-10% | Smooth Operation |

Delrin AF and other PTFE-filled POMs provide excellent wear resistance and low friction for demanding parts. Their self-lubricating nature eliminates the need for external grease, simplifying design and extending the operational life of components. This makes them a superior choice for many mechanical applications.

Material Properties Profile: Stiffness, Creep, and Impact Resistance

When selecting a material for long-term mechanical performance, a few key properties stand out. Materials like Delrin are chosen because they reliably maintain their shape and strength under continuous stress. This is crucial for parts that can’t afford to deform over time.

Delrin Creep Resistance

Creep is a material’s tendency to deform permanently under a constant load. Delrin exhibits excellent creep resistance, making it ideal for gears, bearings, and structural components. It holds its dimensions better than many other thermoplastics under similar conditions.

The following table, based on our internal testing data, illustrates this point.

| Property | Delrin 100P | General Purpose Nylon 6/6 |

|---|---|---|

| Tensile Creep Modulus (1000h, 23°C) | ~1,200 MPa | ~700 MPa |

| Stress for 1% Strain (1000h, 23°C) | ~11 MPa | ~6 MPa |

Dimensional Stability

This resistance to creep directly translates to superior dimensional stability. Components made from Delrin maintain their precise tolerances over long service periods, even with fluctuating temperatures and loads. This predictability is vital for high-precision applications.

Understanding the physical properties of Delrin goes beyond a simple datasheet. The interaction between stiffness, impact strength, and long-term stability is what truly defines its performance in demanding applications. You must consider the entire operational environment.

Impact Strength Considerations

While Delrin is very stiff, its standard grades offer moderate impact strength. For applications requiring higher toughness, impact-modified grades are available. However, this often involves a trade-off with stiffness and creep resistance, a factor we always discuss with clients for their mold trials.

Temperature and Load Dynamics

The creep resistance of Delrin is highly dependent on both temperature and the level of applied stress. As temperature increases, the rate of creep accelerates. This is why understanding the part’s thermal environment is non-negotiable for predicting its long-term dimensional stability. It also explains why a phenomenon like Stress Relaxation7 is critical in press-fit assemblies, where maintaining clamping force over time is essential. Having a consistent supply of a specific Delrin grade from our MTM facility ensures that the material tested is the one that will perform as expected in the field.

Delrin’s physical properties offer a powerful combination of stiffness, excellent dimensional stability, and high creep resistance. This makes it a dependable choice for mechanical parts that must perform consistently under continuous load, ensuring long-term reliability in your final product design.

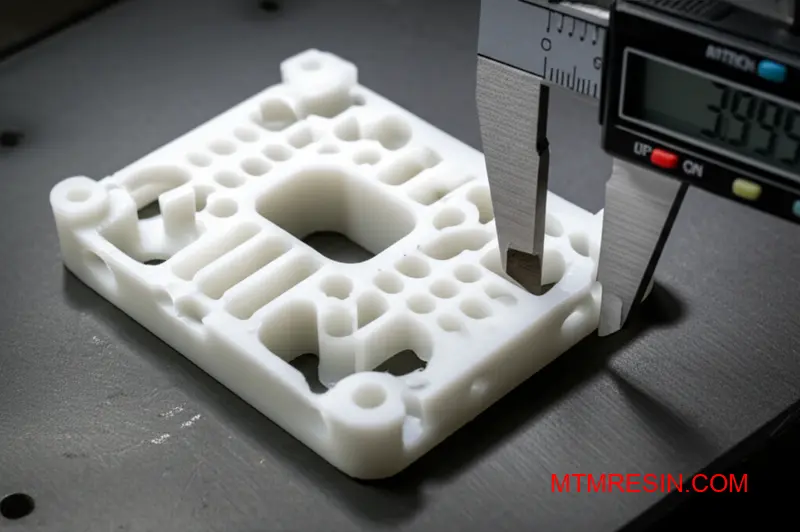

Calculating Shrinkage Rates for Precision Delrin Mold Design

Precision in mold design hinges on accurately predicting material shrinkage. For crystalline materials like Delrin, the shrinkage rate is notably high, often ranging from 1.5% to 3.0%. Ignoring this can lead to out-of-spec parts. Your mold design allowance must account for this behavior from the start.

Understanding Crystalline vs. Amorphous Shrinkage

The molecular structure directly impacts how a material shrinks. Crystalline polymers have a more ordered structure, leading to greater volume change upon cooling.

| Material Type | Typical Shrinkage Range | Example |

|---|---|---|

| Amorphous | 0.3% – 0.8% | PC |

| Crystalline | 1.5% – 3.5% | Delrin (POM) |

Grade-Specific Adjustments

Not all Delrin grades are the same. Additives like glass fibers or fillers significantly alter the shrinkage rate, making grade selection a critical factor in your initial calculations.

Mastering Delrin shrinkage requires moving beyond generic datasheet values. Each grade behaves differently, and factors like wall thickness, gate location, and processing parameters introduce further variables. For instance, a glass-filled Delrin grade will shrink less than an unfilled one, but its shrinkage can be non-uniform.

The Role of Fillers and Anisotropy

Fillers restrict polymer chain movement during cooling, reducing overall shrinkage. However, this can introduce Anisotropy8, where shrinkage differs in the flow and cross-flow directions. Our tests show this can be a major source of warpage if not anticipated in the mold design.

| Delrin Grade | Flow Direction Shrinkage | Cross-Flow Direction Shrinkage |

|---|---|---|

| Unfilled 100P | ~2.0% | ~2.0% |

| 20% Glass-Filled | ~0.5% | ~1.2% |

Why T1 Trials are Non-Negotiable

Theoretical calculations provide a baseline, but the T1 trial is the ultimate reality check. It validates your mold design allowance against real-world conditions. This is where having the exact specified grade, which MTM supplies locally in China, prevents costly delays and ensures your verification process is accurate.

Accurate Delrin mold design requires accounting for high, grade-specific shrinkage rates. While initial calculations are important, the T1 trial is essential for validating these figures, ensuring the final part meets precise dimensional requirements and avoiding costly tool modifications.

Processing Delrin: Optimizing Melt Temperature Windows

Processing Delrin requires precision. Its narrow melt temperature window leaves little room for error. Unlike other polymers, Delrin (POM-H) can quickly suffer from thermal degradation if the settings are incorrect. This makes controlled injection molding settings absolutely critical for success.

Key Temperature Considerations

The ideal Delrin melt temperature ensures proper flow without breaking down the material. We often advise clients to start with the manufacturer’s recommendations and adjust carefully. Monitoring each zone is key.

Recommended Injection Molding Settings

A stable process depends on consistent heat profiles across the barrel. Based on our tests, a typical setup looks something like this.

| Barrel Zone | Temperature Range (°C) | Temperature Range (°F) |

|---|---|---|

| Rear | 180 – 190 | 355 – 375 |

| Middle | 190 – 205 | 375 – 400 |

| Front | 205 – 215 | 400 – 420 |

| Nozzle | 205 – 215 | 400 – 420 |

The main challenge with Delrin is its sensitivity to overheating. Exceeding 220°C (428°F) significantly increases the risk of thermal degradation. This isn’t just about poor part quality; it’s a safety issue. Overheated Delrin releases formaldehyde gas, which is hazardous.

Understanding Degradation Risks

When Delrin degrades, it undergoes a process called Depolymerization9. The long polymer chains break down, severely weakening the material’s structural integrity. This risk makes residence time just as important as temperature. Material should not sit idle in a hot barrel for extended periods.

Signs of Trouble

Identifying degradation early can save a lot of trouble. At MTM, we remind our partners that reliable material from a trusted source is the first step. Consistent batches, like those we stock in China, eliminate material history as a variable. This helps you focus on process parameters.

| Symptom | Common Cause | Impact on Part |

|---|---|---|

| Yellow/Brown Streaks | Excessive Melt Temperature | Poor Aesthetics, Brittle |

| Strong, Pungent Odor | Severe Overheating | Gas Pockets, Weakness |

| Splay or Silvering | Moisture or Gas Traps | Surface Defects |

| Reduced Viscosity | Long Residence Time | Inconsistent Fill, Voids |

Controlling these factors is essential. It ensures that the Delrin parts you produce meet the required mechanical and visual standards for your project.

Mastering Delrin’s narrow processing window is non-negotiable for quality parts. Careful control of melt temperature and residence time is essential to prevent thermal degradation. This precision ensures both part integrity and operational safety.

Troubleshooting Common Defects: Voids, Splay, and Warpage

Molding Delrin (acetal) presents unique challenges. Its semi-crystalline nature makes it prone to specific defects like vacuum voids, especially in thick sections. Warpage after molding is another common issue I encounter when assisting clients with their mold trials. These problems can delay projects significantly.

Identifying Root Causes

Fixing Delrin molding defects starts with accurate diagnosis. Voids often result from insufficient packing pressure or short hold times. Warpage usually stems from uneven cooling or poor part design, causing internal stresses. Understanding the material’s behavior is the first step toward a solution.

Common Causes of Voids

| Cause | Description |

|---|---|

| Low Pack Pressure | Melt pressure is too low to compensate for shrinkage. |

| Short Hold Time | Pressure is not maintained long enough for the gate to freeze. |

| High Melt Temp | Excessive shrinkage occurs as the material cools. |

| Poor Gate Design | Restricts flow and pressure transfer into the cavity. |

Effectively troubleshooting these issues requires a systematic approach. For instance, when dealing with vacuum voids in thick-walled Delrin parts, simply increasing packing pressure is not always enough. You must also manage melt temperature and cooling rates to ensure uniform solidification from the inside out.

Advanced Strategies for Warpage Control

Warpage is often a result of Differential Shrinkage10, where different sections of the part shrink at varying rates. This is a primary concern with materials like Delrin. Based on our tests, we’ve found that balancing mold temperature between the core and cavity sides can significantly reduce this effect.

A consistent material batch is also critical. At MTM, we ensure the Delrin supplied for mold trials is from a single, reliable source. This consistency eliminates material variation as a potential cause, allowing engineers to focus solely on process and mold adjustments. It saves valuable time during the critical trial phase.

Process Adjustments for Warpage

| Parameter | Recommended Action |

|---|---|

| Mold Temperature | Increase to reduce internal stress, ensure uniformity. |

| Cooling Time | Extend to allow for more complete, even crystallization. |

| Injection Speed | Slow down to minimize molecular orientation and stress. |

| Packing Profile | Use a stepped profile to manage shrinkage in different areas. |

Troubleshooting Delrin requires a focus on process control. Addressing vacuum voids and warpage involves carefully balancing pressure, temperature, and cooling. Consistent material properties are fundamental to achieving repeatable results and minimizing defects during critical mold trials.

The Danger of Material Substitution: Generic POM vs. Genuine Delrin

When a procurement team allows a molder to swap specified Delrin for a generic POM, they introduce significant risks. This decision, often driven by a small initial cost saving, can lead to severe long-term consequences. The core issue is a loss of control over material quality and performance.

Hidden Costs of Unapproved Swaps

Authentic Delrin offers consistent, predictable performance backed by extensive data. Generic substitutes lack this assurance. The potential for part failure increases dramatically, directly impacting brand reputation and customer trust. This is a classic example of a short-term gain leading to long-term pain.

Liability and Performance Failure

The most critical risks are liability from product failures and the associated warranty claims. A component made from inferior material can fail unexpectedly, leading to costly recalls or even legal action. Ensuring material authenticity is not just a quality check; it’s a crucial risk management step.

| Risk Factor | Specified Delrin | Generic POM Substitution |

|---|---|---|

| Performance | Consistent & predictable | Highly variable, often poor |

| Liability | Low; backed by data | High; unpredictable failures |

| Brand Reputation | Protected | At risk of damage |

| Long-Term Cost | Lower total cost | Higher due to failures |

The Procurement Gamble

I often advise procurement teams to look beyond the per-kilogram price. The true cost of a material includes the risk of failure. Allowing a substitution for a critical material like Delrin is a gamble where the potential losses far outweigh the initial savings from using counterfeit acetal.

Tracing the Problem

The challenge lies in verification. Without a trusted supply chain, it’s difficult to confirm if the material used is genuine. This is a common issue when working with new or unvetted suppliers. At MTM, we eliminate this uncertainty by providing fully traceable, branded materials like Delrin in China.

Long-Term Performance Under Load

A key differentiator is how materials behave over time. Genuine Delrin is engineered for superior Creep resistance11, meaning it maintains its shape under sustained stress. Many generic POMs perform poorly in this area, leading to part deformation and eventual failure, creating huge material substitution risks.

Our internal testing shows that some generic POMs can lose dimensional stability much faster than Delrin under identical load conditions. This is a critical failure point for components in automotive or consumer electronics, where long-term reliability is non-negotiable. It reinforces the need for ensuring material authenticity.

Substituting specified Delrin for generic POM creates unacceptable risks. This decision compromises product performance, exposes the company to liability, and can damage its reputation. Ensuring material authenticity is not just a best practice; it is essential for risk management and long-term success.

Regulatory Compliance: Locating Medical and Food Grade Delrin in Asia

The Challenge of Sourcing Compliant Delrin

Finding standard Delrin in Asia is often straightforward. The real challenge arises when your project requires specific medical or food-grade resins. These specialized materials demand strict regulatory compliance, a focus not always shared by local suppliers who handle high-volume industrial plastics.

Why Niche Grades are Scarce

This scarcity can halt a project during the critical mold trial phase. Teams frequently encounter long lead times when importing small quantities of FDA-compliant or USP Class VI Delrin. This delay undermines the goal of rapid prototyping and product validation.

| Feature | Standard Delrin | Medical/Food Grade Delrin |

|---|---|---|

| Availability | High | Low (in Asia) |

| Documentation | Basic TDS | Full Regulatory Package |

| Application | General Industrial | Medical Devices, Food Contact |

The Critical Role of Regulatory Documentation

For any project in the medical or food sectors, regulatory documentation is non-negotiable. It forms the foundation of your product validation. A certificate confirming FDA compliance or USP Class VI standards is essential proof that the material is safe for its intended application.

Beyond the Technical Datasheet

Without this paperwork, your mold trial is essentially invalid. Using a non-certified "equivalent" Delrin, even if its mechanical properties seem identical, introduces significant risk. The final product’s Biocompatibility12 cannot be proven, which could lead to expensive re-validation or complete project failure. This is an issue I have seen derail timelines repeatedly.

At MTM, we address this by pre-stocking certified medical and food-grade Delrin. We provide the full documentation package with the material, ensuring your validation process starts correctly from day one, right here in China.

| Validation Step | Key Requirement | Our Solution |

|---|---|---|

| Material Sourcing | Certified Grade Required | Pre-stocked, verified Delrin |

| Documentation | Full Compliance Package | Provided with Material |

| Mold Trial | Use Production-Intent Resin | Immediate Availability |

| Timeline | Avoid Import Delays | Local China Warehouse |

Locating medical and food-grade Delrin in Asia is a major hurdle due to documentation and availability issues. Sourcing from a partner like MTM, who provides certified materials from local stock, eliminates validation risks and keeps your project timelines on track.

Source Genuine Delrin for Mold Trials at MTM

Ready for your Delrin mold trial in China? Eliminate risky substitutions and shipping delays—MTM stocks authentic Delrin grades locally, including 100, 500, and specialty series. Secure the right resin for your application, request a quote now, and ensure your trial’s material accuracy and speed.

-

Understand how this property influences material strength and performance in engineering applications. ↩

-

Understanding this helps predict how a part withstands repeated stress cycles, crucial for long-term component reliability. ↩

-

See how Melt Flow Rate is essential for predicting polymer behavior during injection molding. ↩

-

Understanding its chemistry helps in selecting the right acetal grade. ↩

-

This field helps predict material flow in the mold, crucial for optimizing part quality and production efficiency. ↩

-

Understanding this field is key to designing effective wear-resistant components and predicting material performance. ↩

-

Learn how this concept impacts the long-term integrity of seals and press-fit assemblies. ↩

-

Understanding this concept helps predict and control warpage in fiber-reinforced parts. ↩

-

Understanding this chemical breakdown helps diagnose material failure and improve molding process control. ↩

-

Understanding this concept helps diagnose and solve complex part warpage issues more effectively. ↩

-

Learn how this property affects long-term part stability and performance under constant stress. ↩

-

Understand how material properties affect interaction with biological systems, crucial for medical device safety. ↩