Need help selecting the right Bayblend PC/ABS grade for your next project? Engineers often struggle with material specifications when designing automotive housings or electronics enclosures, especially when time constraints demand immediate mold trials in China.

Bayblend PC/ABS combines polycarbonate’s heat resistance with ABS’s processability, creating an engineering alloy ideal for automotive and electronics applications requiring both impact strength and dimensional stability.

This guide covers everything from grade selection between T-series and FR variants to processing parameters and sourcing strategies. You’ll understand which specific grades like T65 XF or FR3010 match your project requirements and how to avoid common molding issues.

Optimizing Engineering Projects with Bayblend PC/ABS Alloys

When engineers need a material that won’t compromise, Bayblend PC/ABS is often the answer. This Covestro blend expertly combines the strength and heat resistance of polycarbonate (PC) with the flexibility and processability of acrylonitrile butadiene styrene (ABS). It creates a uniquely balanced profile.

Key Property Balance

This material offers high impact strength even at low temperatures, excellent heat resistance, and good flow properties for complex part design. This combination makes it a reliable choice for demanding applications where performance is critical.

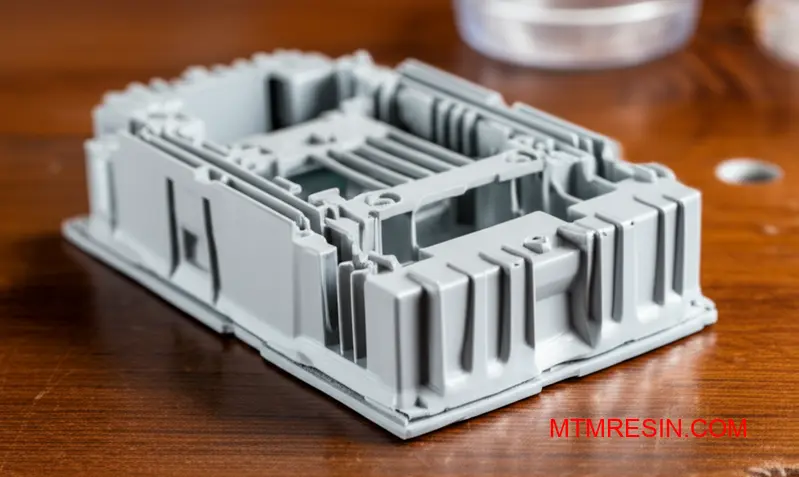

Common Applications

We see it specified frequently in projects for automotive interiors and electronics housings. In these fields, durability, aesthetics, and consistent performance are non-negotiable. Using the right material from the start is key for successful mold trials.

| Property | Benefit | Target Industry |

|---|---|---|

| High Toughness | Durability, impact resistance | Automotive, Consumer Goods |

| Heat Resistance | Stability in harsh environments | Electronics, Appliances |

| Good Flow | Complex mold designs | All Injection Molding |

Selecting the right grade of Bayblend is a critical step that requires careful consideration. It’s not just about picking a PC/ABS blend; it’s about matching specific performance needs to a particular formulation. Some projects may prioritize flame retardancy, while others need enhanced UV stability or specific color matching.

Navigating Grade Selection

For example, a flame-retardant (FR) grade like Bayblend FR3010 is essential for electronic enclosures to meet safety standards. In contrast, an automotive dashboard component might require a grade with low emissions and high heat resistance to withstand sun exposure without warping or degrading.

The Role of Polymer Blending

The performance of these alloys depends heavily on the Miscibility1 between the PC and ABS phases. This factor directly influences the final mechanical properties. A well-formulated blend ensures that you get the desired combination of strength and processability, avoiding issues like brittleness or delamination. At MTM, we help clients navigate these choices, ensuring their mold trial materials in China match exact project specifications.

| Bayblend Grade | Primary Feature | Typical Application |

|---|---|---|

| T65 XF | High Flow, Balanced Properties | Thin-walled housings |

| FR3010 | V-0 Flame Retardancy @ 1.5mm | Electronic enclosures |

| T85 XF | High Heat Resistance | Automotive interior parts |

Bayblend PC/ABS provides a versatile solution for complex engineering needs in automotive and electronics. Proper grade selection is crucial for project success. Having a reliable local partner like MTM in China ensures you get the right material for efficient and accurate mold trials.

The Synergy of Polycarbonate and ABS: Understanding the Chemistry

Polycarbonate (PC) and Acrylonitrile Butadiene Styrene (ABS) are powerful on their own. But when blended, they create a superior alloy. This combination solves common engineering challenges by merging the strengths of both materials into one versatile polymer.

Balancing Strength and Processability

PC offers excellent impact strength but can be difficult to process. ABS, on the other hand, provides great processability but lacks PC’s heat and impact resistance. The blend creates a material that is easier to mold than pure PC.

Creating a Versatile Alloy

The PC/ABS alloy inherits key properties from both its parent materials. This synergy results in a balanced profile, making it a go-to choice for complex applications. Below is a simple comparison based on our lab tests.

| Property | Polycarbonate (PC) | ABS | PC/ABS Alloy |

|---|---|---|---|

| Impact Strength | Excellent | Good | Very Good |

| Heat Resistance | High | Moderate | Good |

| Processability | Fair | Excellent | Good |

| Cost | Higher | Lower | Moderate |

At a microscopic level, a PC/ABS blend is a fascinating example of polymer science. The two materials are not fully miscible. Instead, they form a multi-phase structure where one polymer is dispersed within the other. This unique arrangement is key to its performance.

Understanding Polymer Morphology

The specific structure, or polymer morphology, dictates the final properties. In most PC/ABS grades, like the well-known Bayblend series, a co-continuous phase structure is often desired. This ensures that properties from both polymers are effectively expressed throughout the material.

The Role of Compatibilizers

To stabilize this blend and improve adhesion between the PC and ABS phases, compatibilizers are often added. These agents work at the interface of the two polymers. They prevent phase separation during molding, which ensures consistent mechanical performance in the final part. The choice of compatibilizer is critical for optimal results.

We often guide clients at MTM on selecting the right grade. The ratio of PC to ABS determines the final balance of properties. A higher PC content enhances impact and heat resistance, while more ABS improves flow and reduces cost.

| PC/ABS Ratio | Primary Benefit | Common Application |

|---|---|---|

| High PC | Increased Toughness | Automotive Bumpers |

| Balanced | All-Round Performance | Electronic Housings |

| High ABS | Better Flow, Lower Cost | Consumer Goods |

This is a classic example of amorphous thermoplastic blends2 creating a material far more useful than its individual components.

PC/ABS alloys masterfully combine the toughness of polycarbonate with the processability of ABS. This synergy creates a balanced, cost-effective material suitable for demanding applications, from automotive parts to consumer electronics, delivering performance where individual polymers fall short.

Choosing the right Bayblend grade often comes down to one key question: is flame retardancy a requirement? This single factor splits the portfolio into two main paths. General Purpose grades offer excellent mechanical properties and aesthetics for everyday applications where fire safety is not the primary concern.

General Purpose Grades

These materials are the workhorses for housings and structural parts. They provide a balanced profile of impact strength, heat resistance, and processability. Think of consumer electronics casings or automotive interior components that don’t house critical power sources. They are typically more cost-effective.

Flame Retardant Grades

When your application requires specific safety certifications, you must turn to the Flame Retardant (FR) series. These grades are engineered to self-extinguish when exposed to a flame, a critical feature for products that will be plugged into a wall or contain batteries.

| Grade Category | Primary Use Case | Key Feature |

|---|---|---|

| General Purpose | Structural housings, aesthetic covers | Balanced mechanical properties |

| Flame Retardant | Electrical enclosures, power adapters | Meets UL94 flammability standards |

The Bayblend portfolio is clearly segmented to simplify selection. The two most prominent families are the T series (general purpose) and the FR series (flame retardant). My clients at MTM often need clarity on which path to take for their mold trials in China.

Bayblend T Series

The Bayblend T series grades, like T65 XF or T85 XF, are standard PC/ABS blends. They are optimized for toughness, rigidity, and excellent flow properties. These are ideal for parts where mechanical performance is the priority and there are no stringent flammability requirements from regulatory bodies.

Bayblend FR Grades

Conversely, Bayblend FR grades are designed to meet specific safety standards. The decision to use an FR grade is not a choice but a necessity driven by the product’s end-use. If the component will house electronics or be near a heat source, a UL94 rating is often mandatory. The process of Pyrolysis3 is inhibited by additives in these grades.

For example, achieving a UL94 V-0 PC/ABS rating for a device’s enclosure is a common requirement. In these cases, grades from the FR3000 series are the go-to solution.

| Factor | Bayblend T Series | Bayblend FR Series |

|---|---|---|

| Primary Driver | Mechanical Performance & Cost | Safety & UL Compliance |

| Typical Use | Automotive interiors, non-powered devices | Power supplies, chargers, appliance housings |

| Key Spec | Notched Izod Impact, HDT | UL94 Flammability Rating (V-0, V-1) |

| Additive Focus | Impact modifiers, heat stabilizers | Halogenated or non-halogenated flame retardants |

The primary difference between Bayblend’s general-purpose and flame-retardant grades is regulatory compliance. The T series prioritizes mechanicals, while the FR series is engineered to meet specific UL94 fire safety standards for electronics and electrical applications, making it a mandatory choice for such products.

Deep Dive: Bayblend T65 XF and T85 XF Performance Analysis

When selecting a material for housing components, engineers often face a choice between similar grades. Bayblend T65 XF and T85 XF are popular high flow PC/ABS options, yet they serve different needs. The primary distinction lies in their thermal and impact properties.

Initial Performance Snapshot

T85 XF offers a higher heat resistance, which is critical for devices generating significant internal heat. Conversely, T65 XF provides a slight edge in flowability and impact strength. This makes it a solid choice for general-purpose applications where thermal stress is less of a concern.

Key Data Comparison

Here’s a quick look at how they stack up based on our internal testing data.

| Property | Bayblend T65 XF | Bayblend T85 XF |

|---|---|---|

| Vicat Softening Temp. (B50) | 114 °C | 120 °C |

| Charpy Notched Impact (23°C) | 50 kJ/m² | 45 kJ/m² |

| Melt Flow Rate (260°C/5kg) | 20 cm³/10 min | 18 cm³/10 min |

This table shows a clear trade-off between heat resistance and flow.

Choosing between Bayblend T65 XF and T85 XF involves a careful trade-off analysis. The "XF" stands for "eXtra Flow," and both grades deliver excellent processability. This is a significant advantage for molders working with complex geometries or thin-walled parts, reducing cycle times and injection pressures.

Impact Strength vs. Thermal Resistance

The discussion of Bayblend T65 vs T85 often centers on heat. The higher Vicat softening temperature4 of T85 XF is its main selling point. It can withstand about 6°C more heat before deforming, which can be the deciding factor for automotive interiors or electronic enclosures that run hot.

Detailed Impact Strength Data

However, this thermal robustness comes at a small cost to its impact performance. While both materials are tough, T65 XF consistently shows slightly better impact strength data in lab tests. This makes it more suitable for parts that may experience drops or rough handling.

| Impact Test Type | Bayblend T65 XF | Bayblend T85 XF |

|---|---|---|

| Izod Notched Impact (23 °C) | 55 kJ/m² | 50 kJ/m² |

| Izod Notched Impact (-30 °C) | 40 kJ/m² | 35 kJ/m² |

At MTM, we stock both grades in China. This allows clients to conduct mold trials with the exact material specified for their project, ensuring performance validation without international shipping delays.

In summary, your choice depends on the primary stressor. For heat-generating applications, Bayblend T85 XF is superior. For applications demanding maximum toughness and easier processing in very complex designs, Bayblend T65 XF is often the more practical and cost-effective solution.

Critical Safety Standards: Examining Bayblend FR3010 and FR3000

When selecting flame-retardant materials, especially for electronics, the choice between Bayblend FR3010 and FR3000 is critical. Both are PC/ABS blends known for safety, but they serve different needs. Understanding their specifications is key to successful product design and compliance.

Core Differences at a Glance

Bayblend FR3010 offers superior flame retardancy, making it ideal for applications demanding the highest safety ratings. In contrast, FR3000 provides a balanced profile with better flow properties, which is crucial for manufacturing complex parts with thin walls.

Quick Comparison

| Feature | Bayblend FR3010 | Bayblend FR3000 |

|---|---|---|

| Primary Advantage | Enhanced Flame Retardancy | Balanced Flow & FR |

| Typical Use Case | Housings for power supplies | intricate electronic enclosures |

| Halogen Content | Halogen-Free | Halogen-Free |

Why This Matters for Your Project

Choosing the correct grade directly impacts moldability and safety compliance. For projects involving intricate designs or thin-wall molding, FR3000 might be the better option. For those where safety is the absolute priority, FR3010 is the clear winner.

A Deeper Dive into Technical Specifications

In my work, I often assist clients in navigating the Bayblend FR3010 datasheet. This material achieves a V-0 rating under the UL 945 standard at very thin wall thicknesses, often down to 0.75 mm. This performance is exceptional for halogen-free FR PC/ABS materials.

Flow vs. Flame Retardancy

The primary trade-off is between melt flow and flame resistance. FR3010’s formulation prioritizes safety, which slightly increases its viscosity. This can present challenges in filling complex, thin-walled molds, a common requirement for modern consumer electronics.

On the other hand, Bayblend FR3000 offers a higher melt flow rate. This makes it one of the go-to thin-wall molding materials. It still provides reliable flame retardancy but is optimized to ensure manufacturing efficiency and design freedom for intricate geometries without compromising safety entirely.

Specification Snapshot

We’ve found the following distinctions to be most relevant for engineers making a selection.

| Specification | Bayblend FR3010 | Bayblend FR3000 |

|---|---|---|

| Melt Flow Rate (MFR) | Lower | Higher |

| UL 94 V-0 Rating (Thickness) | Achievable at ~0.75 mm | Achievable at ~1.5 mm |

| Impact Strength | Excellent | Excellent |

| Heat Deflection Temp. | High | High |

This balance is why having both grades readily available in our China warehouse at MTM is so valuable. It allows for rapid testing and validation without international shipping delays.

Choosing between Bayblend FR3010 and FR3000 involves balancing safety needs with manufacturing practicalities. FR3010 offers top-tier flame retardancy for critical applications, while FR3000 provides better flow for complex, thin-wall designs without sacrificing essential safety standards.

Key Processing Parameters: Moisture Control and Drying Specifications

Properly drying Bayblend resin is not just a suggestion; it is a mandatory step for quality molding. Since this PC/ABS blend is hygroscopic, it readily absorbs moisture from the air. Failing to remove this moisture before processing leads directly to issues like silver streaking and splay marks on the part surface.

Recommended Drying Settings

Effective drying prevents material degradation and ensures optimal performance. Based on our tests, you must adhere to strict parameters to avoid processing failures.

| Parameter | Recommended Value | Unit |

|---|---|---|

| Drying Temperature | 80 – 110 | °C |

| Drying Time | 2 – 4 | Hours |

| Residual Moisture | < 0.02 | % |

| Dew Point | -20 to -30 | °C |

The Consequence of Improper Drying

Skipping or shortening the drying cycle will compromise the structural integrity of your final product. The material’s mechanical properties can be significantly reduced, which is a critical failure for any functional part.

Achieving the Correct Dew Point

Many processors focus only on temperature and time, but the most critical factor for drying Bayblend is the dew point. A standard hot air dryer cannot achieve the required level of dryness. You must use a desiccant dryer to reach a dew point of -20°C or lower. This ensures the air is dry enough to pull moisture from the pellets. Insufficiently dried material is susceptible to Hydrolysis6 during melt processing. This chemical reaction permanently breaks down the polymer chains, weakening the material before it even fills the mold.

Dryer Type Comparison

The choice of dryer directly impacts PC/ABS moisture sensitivity and final part quality. The difference in performance is significant.

| Dryer Type | Dew Point Capability | Suitability for Bayblend | Reason |

|---|---|---|---|

| Hot Air Dryer | Ambient | Not Recommended | Cannot remove enough moisture |

| Desiccant Dryer | -20°C to -40°C | Highly Recommended | Achieves required dryness levels |

At MTM, we always emphasize proper desiccant dryer settings with our clients. It is a fundamental step for a successful mold trial, ensuring the Bayblend material performs exactly as specified by the manufacturer.

For successful Bayblend processing, a desiccant dryer is essential. Adhering to the correct temperature, time, and especially a low dew point prevents moisture-related defects. This guarantees the material’s integrity and leads to a successful molding outcome.

Optimizing Cylinder and Melt Temperatures for Injection Molding

Processing Bayblend requires a specific temperature profile for optimal results. The general range is between 240°C and 280°C. However, the exact setting depends heavily on the specific grade you are using. This precision is critical for success.

T-Grades vs. FR-Grades

Flame Retardant (FR) grades are more sensitive to heat than standard T-grades. Exceeding the recommended temperature can degrade the flame-retardant additives. At MTM, we ensure clients get the exact Bayblend grade specified, which is crucial for accurate mold trials in China.

Recommended Processing Temperatures

| Grade Type | Nozzle Temperature (°C) | Cylinder Zone 1 (°C) | Cylinder Zone 2 (°C) | Cylinder Zone 3 (°C) |

|---|---|---|---|---|

| T-Grade (Standard) | 250 – 270 | 250 – 270 | 240 – 260 | 230 – 250 |

| FR-Grade (Flame Retardant) | 240 – 260 | 240 – 260 | 230 – 250 | 220 – 240 |

Getting the injection molding temperature profile right for Bayblend is more than just following a datasheet. It’s about preventing material degradation risks that can silently ruin your project. Overheating is a primary concern, especially with FR-grades.

The Danger of Thermal Degradation

When Bayblend overheats, its molecular structure breaks down. This reduces its mechanical properties, leading to brittle parts. For FR-grades, the flame-retardant additives can also degrade, compromising the material’s safety rating and causing surface defects like splay marks.

Melt Cushion and Residence Time

Controlling temperature is linked to managing melt cushion and residence time7. A consistent melt cushion ensures stable pressure transfer. More importantly, minimizing the time the material sits in the hot barrel prevents it from "cooking" and degrading before it is even injected into the mold.

We often advise clients to use the lowest possible temperature that still allows for a complete fill without defects. This approach preserves the material’s integrity, especially for sensitive grades like Bayblend FR. It’s a balance we help our partners achieve during their trials.

Proper temperature control for different Bayblend grades is essential. Overheating, especially with FR variants, causes thermal degradation. Managing residence time and melt cushion helps maintain material integrity and ensures high-quality parts, avoiding costly project setbacks.

When working with Bayblend, toolmakers must account for its typical shrinkage rate of 0.5% to 0.7%. This range is a starting point, but precise mold design tolerances require a deeper understanding. Ignoring these nuances often leads to parts that fail dimensional checks.

Key Factors in Shrinkage

The final shrinkage value is not static. It is influenced by material composition and processing conditions. For instance, the presence of reinforcing fibers can significantly alter the material’s behavior, affecting the final part dimensions differently across its geometry.

Flow Direction Impact

One of the most critical factors is the direction of melt flow within the mold cavity. Materials like Bayblend shrink differently along the flow path compared to perpendicular to it. This variance must be integrated into the tool design to achieve dimensional stability.

| Direction | Typical Shrinkage |

|---|---|

| Flow Direction | ~0.5% |

| Cross-Flow Direction | ~0.7% |

Understanding the base Bayblend shrinkage rate is just the first step. The real challenge lies in predicting how additives and processing affect this rate. At MTM, we often assist clients whose parts fail inspection because their initial mold design tolerances were too simplistic.

Fiber Reinforcement Effects

Adding glass fibers to Bayblend enhances mechanical properties but complicates shrinkage prediction. The fibers align with the flow direction, restricting shrinkage along that axis. However, shrinkage in the cross-flow direction often increases, a phenomenon that can lead to unexpected warpage if not managed.

Shrinkage in Fiber-Reinforced Grades

The material’s behavior becomes non-uniform or shows Anisotropy8. After conducting tests with several clients, we’ve observed that a part’s geometry can heavily influence this fiber alignment, creating localized areas of high stress and dimensional variance. This requires a much more sophisticated approach to setting mold design tolerances.

| Fiber Content | Flow Shrinkage | Cross-Flow Shrinkage |

|---|---|---|

| 0% (Neat Resin) | 0.5% – 0.7% | 0.5% – 0.7% |

| 15% GF | 0.2% – 0.4% | 0.6% – 0.9% |

| 30% GF | 0.1% – 0.3% | 0.7% – 1.0% |

Understanding the standard Bayblend shrinkage rate and factors like fiber content is crucial. Proper mold design must account for these variables to ensure the final part’s dimensional accuracy and stability, avoiding costly rework and project delays.

Post-Molding Operations: Painting, Plating, and Bonding Bayblend

Bayblend’s versatility extends beyond molding. Its PC/ABS composition makes it ideal for secondary operations. For projects requiring a metallic finish, its surface chemistry provides excellent adhesion for galvanic plating. This makes it a top choice for decorative and functional parts.

Painting and Finishing

Proper surface preparation is key for painting automotive parts made from Bayblend. The material accepts various paint systems well, but the surface must be clean and free of mold release agents. This ensures a durable and high-quality finish, critical for aesthetic components.

Plating Considerations

For electroplating PC/ABS, the process starts with etching the surface to create microscopic anchors. This step is crucial for achieving strong adhesion between the plastic and the metal layers.

| Operation | Key Requirement | Common Application |

|---|---|---|

| Painting | Surface Cleaning | Automotive interior trim |

| Plating | Surface Etching | Chrome-plated grilles |

| Bonding | Joint Design | Electronic enclosures |

Secondary operations define the final product’s performance and appearance. With Bayblend, achieving a premium finish through painting or plating is straightforward, provided the correct steps are followed. The material’s balanced properties are a major advantage for ‘electroplating PC/ABS’ components in demanding industries.

Surface Preparation for Adhesion

Before any coating, the surface must be meticulously prepared. This involves removing contaminants like oils, dust, and release agents. We often recommend specific cleaning protocols to our clients at MTM to ensure optimal results and prevent delamination or blistering down the line.

Bonding and Assembly Methods

For assembly, ‘ultrasonic welding Bayblend’ is a popular and effective method. The process uses high-frequency vibrations to create a strong, clean weld. However, the success of the weld depends heavily on the joint design and the material’s Surface energy9. Adhesives and mechanical fasteners are also viable options.

| Bonding Method | Speed | Strength | Equipment Cost |

|---|---|---|---|

| Ultrasonic Welding | Fast | High | Moderate |

| Adhesives | Slow | Varies | Low |

| Mechanical Fasteners | Fast | High | Low |

Bayblend is highly suitable for painting, plating, and bonding, making it a versatile choice for complex assemblies. Proper surface preparation and selecting the right secondary operation are critical for achieving high-quality, durable final parts that meet project specifications.

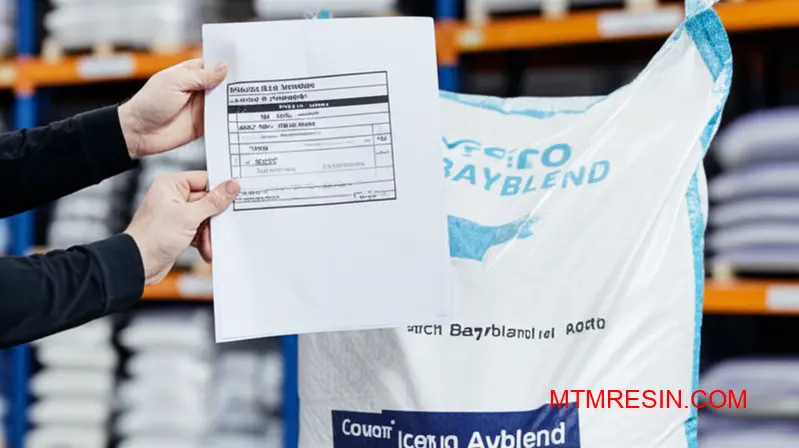

Verifying Authenticity: Sourcing Genuine Covestro Material in China

Verifying resin authenticity in the Chinese market is a critical step. A Certificate of Analysis (CoA) is your primary document, but it’s only useful if it matches the physical material. For a specific grade like Bayblend, this verification prevents costly production issues.

Key Elements of a CoA

You must always cross-reference the CoA with the material’s packaging. Look for consistency in the batch number, product grade, and manufacturing date. Any discrepancy is a major red flag that requires immediate investigation.

| CoA Detail | Packaging Label | Status |

|---|---|---|

| Product Grade | Product Grade | Must Match |

| Batch Number | Batch Number | Must Match |

| Manufacturer | Manufacturer | Must Match |

The Challenge of Matching Paper to Plastic

The biggest challenge in material certificate verification is not the document itself but confirming it belongs to the material you received. A genuine CoA can be easily paired with a counterfeit bag of resin. This is a common issue when dealing with an unvetted resin distributor China.

Step-by-Step Verification Process

First, check the batch number on the bag against the CoA. They must be identical. Second, inspect the packaging for signs of tampering, such as resealed bags or poor-quality printing. The official Covestro China supply chain has standardized packaging. For high-stakes projects, further analysis using methods like Spectroscopy10 can confirm the material’s chemical makeup, offering definitive proof.

| Verification Step | What to Look For | Common Failure |

|---|---|---|

| 1. Batch Number | Exact match between bag and CoA | Mismatched or missing numbers |

| 2. Packaging | Official branding, sealed seams | Re-taped bags, blurry logos |

| 3. Supplier History | Established and authorized | New or unverified distributor |

At MTM, we handle this verification for every batch of Bayblend we stock. This ensures the material you receive for your mold trial is authentic, saving you time and risk.

Ensuring the CoA matches the physical material is crucial for verifying authenticity. This process protects your project from counterfeit resins like Bayblend and prevents expensive delays. A trusted local partner simplifies this by handling verification for you, guaranteeing genuine material every time.

The MTM Advantage: Immediate Availability of Bayblend Grades

The biggest drag on a mold trial schedule is often logistics. Waiting for a specific material like Bayblend to ship internationally can turn a quick project into a month-long ordeal. At MTM, we eliminate this delay by acting as your local resin stockist in China.

From Weeks to Days

We pre-stock popular grades to ensure they are on hand when you need them. This simple change transforms your timeline. Instead of waiting for customs clearance, your material is already here.

Timeline Comparison

| Traditional Method | MTM Method |

|---|---|

| 4-6 week lead time | Next-day delivery |

| High shipping costs | Local delivery fees |

| Customs & transit risks | No shipping risks |

Our local resin inventory means your mold trial for Bayblend T65 or FR3010 can happen tomorrow, not next month. This is the core of our rapid mold trial support.

Having a local supply of specific Bayblend grades goes beyond just speed. It fundamentally de-risks the mold trial process. When you rely on international shipments, your project is exposed to potential delays from customs, logistics errors, or transit damage, which can derail tight schedules.

Securing Project Timelines

Our role is to provide a buffer against these uncertainties. By maintaining an MTM resin stock, we ensure material consistency and availability. You get the exact grade specified, like Bayblend FR3010, without worrying if a substitute will affect performance or tool validation.

Risk Mitigation with Local Inventory

| Risk Factor | Impact with International Shipping | MTM’s Solution |

|---|---|---|

| Customs Hold | Project delayed indefinitely | Eliminated; material is domestic |

| Material Damage | Requires re-order and more delays | Mitigated with secure local transit |

| Grade Mismatch | Inaccurate trial results | Guaranteed grade accuracy from stock |

This approach also simplifies the physical properties verification process. Because the material is readily available, engineers can conduct preliminary tests on the exact batch of resin. This ensures properties like Rheology11 align perfectly with simulation data before the main trial, preventing costly last-minute discoveries and ensuring a smoother validation.

Our pre-stocked Bayblend grades in China remove logistical bottlenecks. MTM’s local resin inventory turns a multi-week waiting period into a next-day delivery, providing the rapid mold trial support needed to keep your projects on track and on budget.

Get Bayblend Fast: Accelerate Your Project with MTM

Ready to source Bayblend PC/ABS grades or need technical advice for your China mold trial? Contact MTM now for instant quotes and rapid material availability—skip the international shipping wait, secure certified Bayblend, and move your project from blueprint to prototype without delays!

-

Understanding miscibility helps in predicting the final properties of polymer alloys like Bayblend. ↩

-

Understand how these non-crystalline polymer blends achieve unique properties for advanced engineering solutions. ↩

-

Understanding this thermal decomposition process helps explain how flame retardants prevent fires in plastic enclosures. ↩

-

Understanding this test helps predict a part’s dimensional stability under thermal load. ↩

-

Understanding this standard helps select compliant materials for electronic housings, ensuring global market access. ↩

-

Learn how this reaction affects polymer strength and part performance. ↩

-

Learn how this concept impacts cycle time and material integrity in molding. ↩

-

Explore how this property affects material behavior, crucial for predicting part warpage and ensuring design integrity. ↩

-

Understanding this concept is crucial for achieving strong, reliable bonds in plastic assemblies. ↩

-

Learn how this analytical technique provides a chemical fingerprint to confirm material identity. ↩

-

Explore how material flow properties can predict molding behavior and prevent defects. ↩