Are you tired of waiting weeks for your Lexan resin to clear customs while your mold trial deadline approaches? Many project managers face this exact nightmare – watching their carefully planned schedules crumble because the right polycarbonate grade is stuck in shipping delays or customs clearance.

Optimizing your Lexan resin strategy requires understanding grade selection fundamentals and having reliable access to materials for China mold trials. The key lies in matching specific Lexan grades to your application requirements while ensuring consistent material availability during the critical trial phase.

I’ve worked with engineering teams who struggled with Lexan grade selection and trial material logistics. Getting the right grade matters, but having it available when you need it makes the difference between meeting deadlines and costly delays.

Decoding the Lexan Nomenclature: A Guide for Procurement Managers

Navigating SABIC’s Lexan grade nomenclature can feel overwhelming. A wrong digit or letter can lead to incorrect material orders, causing delays and added costs for your mold trials. The key is to break the code down into its core components.

Understanding the Basic Structure

Most Lexan grades follow a pattern that tells you about the base resin, additives, and color. Misinterpreting this can mean getting a material with the wrong impact strength or flame retardancy. This guide helps you avoid that.

A Simple Breakdown

Here’s a simplified look at how these codes are structured. Understanding this framework is the first step in ensuring you procure the correct Lexan grade for your project needs.

| Code Section | Represents | Example (940A-116) |

|---|---|---|

| Numeric | Base Resin Series | 940 |

| Suffix (A-Z) | Additive Package | A |

| Suffix (#) | Color Code | 116 |

Diving Deeper into Specific Series

The numeric part of the code is crucial. It often indicates the viscosity and general application suitability. For example, the 100 series is for general-purpose molding, while the 900 series usually denotes flame-retardant grades with specific agency compliance.

Suffixes: The Key to Properties

The letter suffixes reveal the additive packages. An ‘A’ typically signifies a non-halogenated flame retardant, while an ‘R’ points to a mold release agent. Omitting these details can significantly alter material performance during the molding process. In our work, we’ve seen how a missing ‘R’ can lead to parts sticking in complex molds.

The Role of Material Rheology1

Understanding how these additives affect the material’s flow behavior is critical. Additives change the polymer’s viscosity and processing window. This directly impacts everything from mold filling to the final part’s appearance and structural integrity.

| Grade Example | Base Characteristic | Primary Additive | Common Application |

|---|---|---|---|

| Lexan 141R | General Purpose, Low Viscosity | Mold Release (R) |

Thin-walled parts |

| Lexan 940A | Flame Retardant | Non-Halogenated FR (A) |

Electronics enclosures |

| Lexan HF1110 | High Flow | Internal Lubricant | Fast-cycle applications |

At MTM, we help clients cross-reference these codes to ensure the material sourced in China precisely matches their project’s requirements, preventing trial-and-error cycles.

Mastering Lexan’s nomenclature is essential for accurate procurement. Understanding the base series, additive suffixes, and color codes prevents costly errors and ensures your mold trial materials in China are correct from the start, accelerating your project timeline.

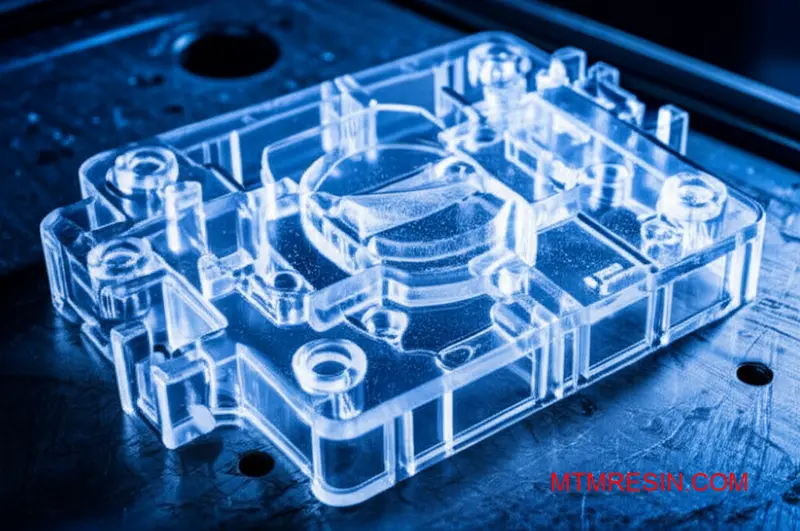

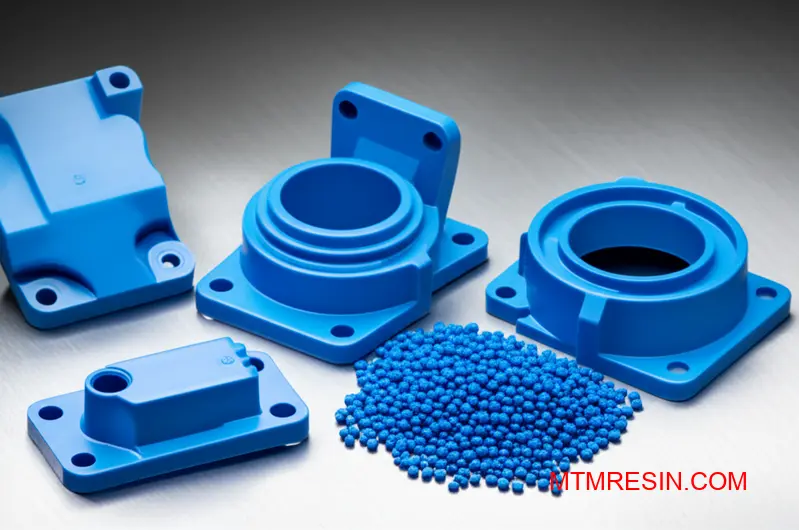

General Purpose vs. High Flow Lexan: Matching Grade to Part Geometry

Choosing the right Lexan grade isn’t just about color or basic properties. The geometry of your part is the most critical factor. A general-purpose grade works well for robust parts, but complex, thin-wall designs present a different challenge.

Understanding the Basics

General-purpose (GP) polycarbonate like Lexan 121R has a standard viscosity. High-flow (HF) grades like Lexan 141R are engineered to fill intricate molds more easily. This difference is crucial during mold trials, where success depends on getting it right the first time.

Quick Grade Comparison

Here is a simple breakdown of two common Lexan grades we often supply at MTM for trials.

| Property | Lexan 121R (General Purpose) | Lexan 141R (High Flow) |

|---|---|---|

| Primary Use | Thicker, less complex parts | Thin-wall, intricate designs |

| Melt Flow | Lower | Higher |

| Injection Pressure | Higher pressure required | Lower pressure required |

| Cycle Time | Potentially longer | Potentially shorter |

Failing to match the grade to the geometry often leads to costly molding defects.

When your design features thin walls, long flow paths, or complex details, a standard polycarbonate may struggle. The material can cool and solidify before completely filling the mold cavity. This results in a "short shot," a critical defect that renders the part useless.

The Role of Flow Rate

High-flow Lexan grades are designed specifically to overcome this. Their lower viscosity allows the molten plastic to travel faster and farther with less pressure. This is essential for thin-wall injection molding, where the material must fill sections often less than 1mm thick. Choosing a high-flow grade can be the difference between a successful trial and a failed one.

Beyond Short Shots

The Melt Flow Index2 (MFI) is a key metric here. A higher MFI, like that of Lexan 141R, indicates better flowability. However, higher flow is not a universal solution. In a poorly designed mold, it can lead to flashing, where excess material seeps out of the mold cavity.

| Challenge | Recommended Approach | Consequence of Mismatch |

|---|---|---|

| Thin Walls (<1.5mm) | Use high-flow Lexan (e.g., 141R) | Short shots, surface defects |

| Complex Geometries | Use high-flow Lexan | Incomplete fill, weak knit lines |

| Thick, Simple Parts | Use general-purpose Lexan (e.g., 121R) | Potential for sink marks with HF grades |

At MTM, we stock both types in China, ensuring your team has the right material ready for trial without international shipping delays.

Matching Lexan grade to part geometry is critical. General-purpose grades suit simple, robust parts, while high-flow variants are essential for complex, thin-wall designs to prevent defects like short shots and ensure a successful mold trial.

When developing products for electronics or electrical enclosures, flame retardancy is not optional. It’s a critical safety requirement. Many of my clients need materials that meet stringent standards, and the Lexan 940 and 920 series are often the top contenders.

Understanding the Basics

The key difference lies in their appearance and formulation. The Lexan 940 series is opaque, offering excellent colorability and performance. In contrast, the Lexan 920 series provides similar flame-retardant properties in a transparent grade, which is crucial for applications requiring visibility.

Key Series Comparison

| Feature | Lexan 940 Series | Lexan 920 Series |

|---|---|---|

| Appearance | Opaque | Transparent |

| FR Standard | UL94 V-0 | UL94 V-0 |

| Primary Use | Enclosures, Housings | Lenses, Covers, Light Pipes |

The most crucial requirement for many electronics applications is the UL94 V-0 rating. This standard signifies that a material will self-extinguish within 10 seconds after two applications of a flame in a vertical burn test. Both Lexan series excel here, but their applications differ significantly.

The Opaque Workhorse: Lexan 940 Series

The Lexan 940 series, particularly grades like 940A, is a go-to for internal components and device housings. Its opaque nature is ideal for hiding internal wiring while providing robust protection. We see it used frequently in power adapters, server chassis, and consumer electronics casings. The excellent Lexan 940A properties ensure dimensional stability and impact resistance.

The Transparent Protector: Lexan 920 Series

When visibility is necessary, the Lexan 920 series is the clear choice. Think of transparent covers for circuit breakers or light pipes in equipment. The Lexan 920A UL rating confirms it provides V-0 safety without compromising optical clarity. This is a significant engineering advantage.

Advanced FR Technology

Both are non-chlorinated, non-brominated flame retardant resins, meeting modern environmental standards like RoHS. They often rely on a phosphorous-based intumescent3 system. This technology works by charring and swelling on the surface, creating an insulating barrier that suffocates the flame. When we run mold trials at MTM, having these specific Lexan grades pre-stocked in China prevents major project delays for our clients.

Choosing between Lexan 940 and 920 depends on your application’s need for transparency versus opacity. Both series provide reliable UL94 V-0 rated performance, ensuring your product meets critical safety standards without compromise. Sourcing the correct grade early is key.

Enhancing Structural Integrity: When to Specify Glass-Reinforced Lexan 500 Series

When a project demands more than standard polycarbonate can offer, the Lexan 500 series is a material I often recommend. By reinforcing the polymer with glass fibers, we dramatically increase its strength and stiffness, opening up applications where plastic traditionally couldn’t compete with metal.

Key Performance Gains

The primary benefit is a significant boost in mechanical properties. This enhancement makes glass-reinforced polycarbonate, like Lexan, an excellent candidate for structural components that require high rigidity and durability without the weight of metal.

Strength and Modulus Comparison

Our internal tests show clear advantages when comparing standard PC to a glass-filled grade. The material becomes substantially stronger and less prone to bending under load.

| Property | Standard Polycarbonate | Lexan 503R (30% Glass) |

|---|---|---|

| Tensile Strength | ~60 MPa | ~120 MPa |

| Flexural Modulus | ~2.4 GPa | ~8.6 GPa |

This jump in performance allows engineers to design robust yet lightweight parts.

Navigating the Engineering Trade-Offs

While the Lexan 500 series offers immense benefits, it’s crucial to understand the associated compromises. Adding glass fibers is not a simple upgrade; it changes how the material behaves during and after molding.

Surface Finish Considerations

The glass fibers can disrupt the smooth flow of the resin against the mold surface. This often results in a less glossy, more fibrous appearance compared to unfilled grades. For parts where cosmetics are critical, this is a key factor to evaluate during the mold trial.

Impact on Tooling

Glass is abrasive. Over many production cycles, glass-filled polycarbonate will cause more wear on molds than standard resins. I always advise clients to consider using hardened steel for their tooling if they plan for high-volume production with a material like Lexan 500R.

From Metal to Plastic: Key Advice

Replacing metal with glass-filled PC is more than a material swap. It requires rethinking part design to leverage the unique properties of plastic. One must account for the material’s different modulus of elasticity4 and anisotropic behavior due to fiber alignment.

| Aspect | Engineering Recommendation |

|---|---|

| Part Geometry | Add ribs and gussets to maximize stiffness where needed. |

| Gating Strategy | Gate location influences fiber orientation and final strength. |

| Tool Steel | Specify P20 is not a good option, H-13 or S-7 for longevity. |

At MTM, we assist teams in navigating these challenges by supplying the right Lexan grades for trials, ensuring designs are validated before committing to expensive production tooling.

The Lexan 500 series provides a powerful metal-replacement solution. Success requires balancing its enhanced stiffness and strength against potential trade-offs in surface finish and tool wear. Proper engineering consideration during the design phase is essential for optimal results.

Impact Resistance in Cold Environments: Utilizing Lexan EXL Resin

Designing for cold environments presents unique challenges. Standard polycarbonate is known for its toughness, but its performance can falter as temperatures drop. This shift toward brittleness can cause unexpected failures in products intended for outdoor or refrigerated use, a common concern for our clients.

The Problem with Standard PC

Standard polycarbonate loses its ductility in the cold. This means instead of bending or deforming upon impact, it is more likely to crack or shatter. This property shift can compromise the integrity of critical components in automotive, telecommunications, and consumer electronics applications.

Introducing Lexan EXL Resin

Lexan EXL resin is an engineered solution to this problem. This copolymer maintains excellent impact resistance at very low temperatures. It provides the reliability needed for components that must perform consistently, regardless of the weather.

| Feature | Standard PC | Lexan EXL Resin |

|---|---|---|

| Performance at -30°C | Becomes Brittle | Stays Ductile |

| Impact Strength | Significantly Reduced | Maintained |

| Ideal Applications | Indoor Devices | Outdoor Enclosures |

The primary issue with standard polycarbonate in cold is its polymer structure. As temperatures fall, the polymer chains lose mobility. This stiffness prevents the material from effectively absorbing and dissipating impact energy, leading to brittle failure instead of ductile deformation.

The Silicone Copolymer Advantage

Lexan EXL resin is a silicone polycarbonate copolymer. The integration of flexible silicone into the rigid polycarbonate backbone is the key. This unique chemistry enhances polymer chain mobility even at extremely low temperatures, preserving the material’s inherent toughness.

Low-Temperature Ductility

The most critical benefit is maintaining ductility. After reviewing test results with clients, we confirmed that parts molded from Lexan EXL resin can withstand impacts down to -40°C without fracturing. This makes it an ideal choice for durable outdoor equipment. This is where the concept of Ductile-to-Brittle Transition Temperature5 becomes very important in material selection.

| Property | Standard PC (at -40°C) | Lexan EXL Resin (at -40°C) |

|---|---|---|

| Failure Mode | Brittle Fracture | Ductile Failure |

| Energy Absorption | Low | High |

| Reliability | Poor | Excellent |

At MTM, we keep materials like Lexan EXL in our China warehouse. This ensures that when your mold is ready for trial, you have the correct high-performance resin available immediately. You can avoid shipping delays and validate your design for harsh conditions without compromise.

Lexan EXL resin effectively addresses the low-temperature brittleness of standard PC. Its silicone copolymer chemistry ensures reliable impact performance in cold climates, making it a superior material choice for demanding outdoor and industrial applications where failure is not an option.

Healthcare and Biocompatibility: Selecting Lexan HP Grades for Medical Molds

When developing medical devices, material selection is critical. The Lexan HP series is specifically designed for these demanding applications. These materials must meet stringent requirements far beyond those of standard plastics. Success depends on understanding these unique needs from the start.

Sterilization and Compliance

Medical components often undergo sterilization. The chosen material must withstand methods like gamma irradiation or Ethylene Oxide (EtO) gas without degrading. Additionally, compliance with standards such as FDA and ISO 10993 is non-negotiable for patient safety.

Key Material Properties

The Lexan HP portfolio offers grades tailored for different sterilization methods. Selecting the right one ensures the final product maintains its integrity and performance after processing. This initial choice impacts the entire project timeline.

| Sterilization Method | Impact on Polycarbonate | Suitable Lexan Grade Type |

|---|---|---|

| Gamma Irradiation | Can cause yellowing, reduced ductility | Gamma-stabilized grades (e.g., HP1) |

| Ethylene Oxide (EtO) | Minimal material impact, concerns on residuals | Most HP grades compatible |

| Steam Autoclave | High heat and moisture can cause hydrolysis | High-heat resistant grades |

Navigating Medical Grade Specifications

Choosing a material simply labeled "medical grade" is not enough. You must dig deeper into the specific data sheets. The Lexan HP series, for example, has distinct grades formulated for different end-use environments and regulatory pathways.

Biocompatibility Testing Insights

A material’s biocompatibility is confirmed through rigorous testing outlined in standards like ISO 10993. This testing evaluates how the material interacts with the human body. It is a costly and time-consuming process, which is why using a pre-certified resin like Lexan is crucial. It saves significant development time.

The data from these tests helps engineers ensure their device is safe for its intended contact type and duration. This is not a step where you can afford surprises, especially during mold trials in China. Having the exact specified material ready is essential.

Impact of Sterilization on Polymers

Different sterilization methods affect polymers differently. Gamma radiation, for instance, can cause Chain scission6 in the polymer, leading to brittleness. Lexan HP grades designed for gamma resistance contain additives that mitigate this damage, preserving mechanical properties. EtO sterilization is gentler on the material itself.

| Lexan Grade Example | Primary Sterilization Compatibility | Key Features |

|---|---|---|

| Lexan HP1R | Gamma, EtO | High clarity, gamma stabilized |

| Lexan HPS1R | Steam Autoclave, Gamma, EtO | High heat resistance, opaque |

| Lexan HP4R | EtO, Gamma | Good balance of properties, lubricated |

Selecting the correct Lexan HP grade is vital. It requires matching the material’s properties with the device’s specific sterilization method and biocompatibility requirements. This ensures regulatory compliance and product performance, preventing costly delays in your project schedule.

Lexan vs. Makrolon: A Technical Comparison for Alternative Sourcing

When sourcing polycarbonate, SABIC’s Lexan and Covestro’s Makrolon are the top contenders. For procurement and engineering teams, understanding their equivalency is not just about cost savings; it is crucial for supply chain resilience. Both are premium brands with a strong reputation for quality.

However, relying on a single source can halt production during a shortage. Knowing the alternative is key. At MTM, we frequently guide clients through this comparison, ensuring their mold trials in China proceed without delay, regardless of material availability from a specific manufacturer.

High-Level Property Overview

While datasheets show many similarities, minor differences exist. These nuances can influence processing parameters or final part performance. A basic comparison helps frame the discussion for choosing a suitable alternative.

| Property | SABIC Lexan (General Purpose) | Covestro Makrolon (General Purpose) |

|---|---|---|

| Clarity | Excellent | Excellent |

| Impact Strength | Very High | Very High |

| Heat Resistance | Good | Good |

| UV Stability | Grade Dependent | Grade Dependent |

Grade-Level Cross-Reference

A true one-to-one comparison requires looking at specific grades. General-purpose grades like Lexan 141R and Makrolon 2805 are often considered interchangeable. Both offer a good balance of properties for many injection molding applications. We have seen them used for similar projects.

However, our internal tests show subtle variations. For example, one grade might exhibit a slightly better melt flow, which can be advantageous for thin-walled parts. These small differences are why a quick mold trial with the alternative material is so important before committing to mass production.

Performance Nuances in Practice

Technical specifications like the Notched Izod Impact7 value are critical for performance-driven parts. While equivalent grades have similar ratings, small deviations can matter in applications requiring maximum toughness. It is essential to verify these details to avoid unexpected failures.

This is where having a reliable local partner in China like MTM becomes invaluable. We provide the material and the data to help you make an informed decision quickly, keeping your project timeline intact.

| Feature | SABIC Lexan 141R | Covestro Makrolon 2805 |

|---|---|---|

| MFR (300°C/1.2kg) | ~10 g/10 min | ~10 g/10 min |

| Primary Use | General Purpose Molding | General Purpose Molding |

| Key Attribute | Good Processability | High Toughness, Good Clarity |

| Status | Widely Available | Widely Available |

Both Lexan and Makrolon are excellent choices. The best option depends on supply chain stability, specific performance needs, and regional availability. Having a pre-vetted alternative like Makrolon for a Lexan-specified project is a smart contingency plan that protects your production schedule.

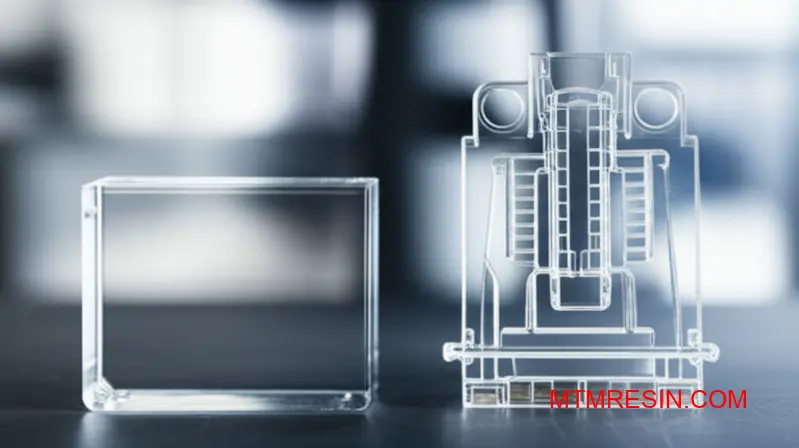

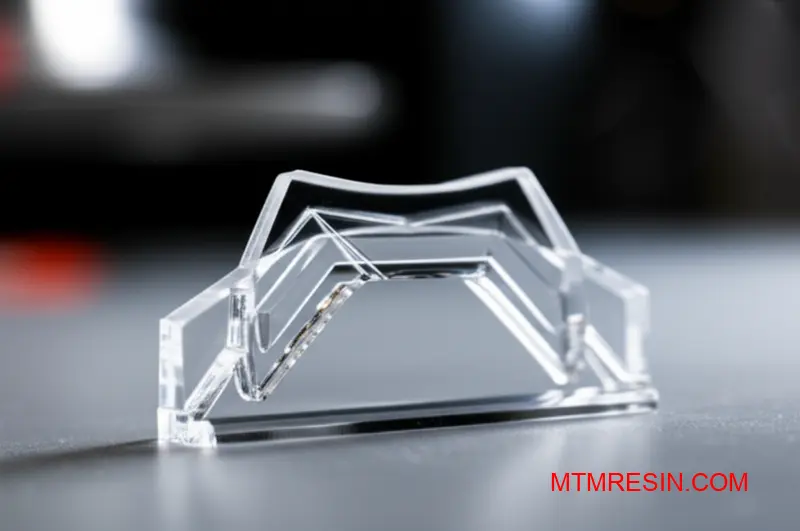

Controlling Mold Temperature for Optical Clarity and Stress Reduction

Mold temperature is a critical factor when molding clear parts from materials like Lexan. It directly influences both optical clarity and internal stress. A higher mold temperature generally allows the polymer molecules more time to relax before solidifying, leading to a superior surface finish.

The Impact on Transparency

For optical applications, a well-controlled, higher mold temperature is essential. It helps create a smoother, more uniform surface that minimizes light scattering. This results in parts with higher transparency and fewer visual defects like flow lines or haze, which are common issues with polycarbonate.

Managing Internal Stress

Simultaneously, a higher mold temperature reduces the amount of molded-in stress. As the Lexan material cools more slowly, the polymer chains settle into a less stressed state. This is vital for parts that must withstand impacts or exposure to chemicals, as high internal stress can lead to premature failure.

| Parameter | Low Mold Temperature | High Mold Temperature |

|---|---|---|

| Surface Finish | Dull, may show flow lines | Glossy, high clarity |

| Internal Stress | High | Low |

| Optical Quality | Poor, potential for haze | Excellent, high transparency |

| Cycle Time | Shorter | Longer |

Controlling the mold temperature for polycarbonate is a balancing act. While a higher temperature improves the part, it often extends the cycle time. The key is to find the optimal temperature that delivers the required quality without making the process inefficient. This is where consistent material is crucial; at MTM, we ensure our Lexan resin is reliable batch-to-batch.

Polymer Chain Relaxation

A warmer mold surface keeps the polymer molten for longer. This extra time allows the stretched polymer chains to relax and untangle from the stresses of injection. The result is a more stable and uniform internal structure. This significantly reduces Birefringence8, an optical effect that reveals stress patterns when viewed under polarized light.

Annealing as a Secondary Process

Sometimes, even with optimal molding, some residual stress remains. For extremely demanding optical or mechanical applications, post-mold annealing is an option. This process involves heating the polycarbonate parts in an oven to a temperature below their softening point to further relieve internal stress.

| Process Stage | Objective | Recommended Temp. (Lexan) |

|---|---|---|

| Injection Molding | Minimize initial stress | 80°C – 120°C (175°F – 250°F) |

| Annealing (Optional) | Relieve residual stress | 120°C – 130°C (250°F – 265°F) |

Proper mold temperature control is the first and most important step in producing high-quality Lexan parts. It directly impacts optical clarity and mechanical integrity by minimizing molded-in stress. Annealing is a secondary option for parts requiring maximum performance and dimensional stability.

Solving Warpage Issues in Large Flat Lexan Panels

Warpage in large, flat Lexan panels, such as tablet screens or electronic housings, is a frequent issue. This deformation stems from uncontrolled internal stresses developed during the molding process. Successfully managing this requires a deep understanding of several interacting factors.

The Core Problem: Internal Stress

The root cause is almost always non-uniform shrinkage. When one area of the part cools and solidifies at a different rate than another, it creates a "tug-of-war" within the material. This internal battle results in the final part bending or twisting.

Primary Causes to Investigate

Controlling warpage in Lexan means controlling shrinkage. The main areas to focus on are differential cooling rates across the part, inconsistent packing pressure, and abrupt changes in the part’s wall thickness. Each contributes to the final stress state.

To achieve true warpage control, we must dissect the molding process. It’s not about a single magic setting but a balanced approach. The goal is to minimize residual stress by ensuring the part cools and solidifies as uniformly as possible.

Managing Thermal and Pressure Variables

Differential cooling is a major offender. If the core and cavity sides of the mold have different temperatures, the Lexan will shrink unevenly. A carefully designed cooling layout is essential for large parts. This ensures heat is extracted uniformly from the entire surface area.

Packing pressure profiles must also be optimized. A proper profile compensates for material shrinkage as it cools. Incorrect pressure can either over-pack some areas or under-pack others, both of which introduce stress. We’ve seen that even with perfect cooling, Anisotropic Shrinkage9 can cause issues if not accounted for.

Design and Material Consistency

Wall thickness transitions are critical. Sharp corners or sudden shifts from thick to thin sections create hot spots and stress concentrators. Gradual transitions are always better for large part injection molding. Below is a simple guide for troubleshooting.

| Issue | Potential Cause | Recommended Action |

|---|---|---|

| Part bows inward | Core side is too hot | Increase core side cooling flow |

| Part bows outward | Cavity side is too hot | Increase cavity side cooling flow |

| Warpage near gate | High packing pressure | Reduce packing pressure and time |

| Inconsistent warp | Material variation | Use a consistent material batch |

At MTM, we ensure our clients receive a consistent batch of Lexan for their trials, which helps isolate process variables from material inconsistencies during troubleshooting.

Controlling warpage in large Lexan panels requires a systematic approach. By carefully managing differential cooling, optimizing the packing pressure profile, and designing for uniform wall thickness, you can significantly reduce residual stress and produce flatter parts.

Color Matching Consistency: Handling Custom Colored Lexan in China

Achieving consistent color in custom colored Lexan parts is a common challenge. When working across different production batches in China, even small variations can lead to noticeable differences. The key metric here is Delta E, which measures the perceived color difference.

Understanding Delta E

Delta E represents the distance between two colors in a color space. A lower value means a closer match. For most applications, a Delta E below 1.0 is considered imperceptible to the human eye. This is the standard we aim for.

Why Batch Consistency Matters

Inconsistent color can ruin a product’s aesthetic and perceived quality. Imagine components of a single device, made from different batches of Lexan, not matching perfectly. This signals poor quality control to the end-user.

| Delta E Value | Perceived Color Difference | Acceptability |

|---|---|---|

| < 1.0 | Not perceptible by human eye | Excellent |

| 1.0 – 2.0 | Perceptible through close observation | Good |

| 2.0 – 3.5 | Clearly perceptible | Acceptable for some applications |

| > 3.5 | Different colors | Unacceptable |

The challenge deepens when deciding between using a masterbatch versus a pre-colored resin. While masterbatch offers flexibility, it introduces variables that can compromise color consistency. Local operators might mix ratios incorrectly or use inconsistent base resins. This is a frequent source of color deviation in Lexan parts.

Masterbatch vs. Pre-Colored Resin

Using a pre-colored, custom compound is the superior method for ensuring consistency. The color is compounded directly into the Lexan resin by the material supplier under controlled conditions. This eliminates the risk of on-site mixing errors at the molding facility. It also prevents issues like Metamerism10, where colors match under one light source but not another.

| Feature | Masterbatch | Pre-Colored Resin |

|---|---|---|

| Consistency | Lower; depends on mixing ratio | Higher; controlled compounding |

| Risk of Error | High; operator dependent | Low; pre-mixed professionally |

| Initial Cost | Can be lower for small volumes | Higher, but ensures quality |

| Material Handling | Requires precise dosing equipment | Simpler; ready to use |

At MTM, we address this by stocking specific, pre-colored Lexan resins in China. This ensures that every mold trial uses material from a consistent, reliable batch, providing an accurate preview of mass production quality and color.

Achieving consistent color in custom Lexan projects is critical. Using pre-colored, compounded resins instead of masterbatch eliminates key variables. This strategy, supported by a reliable local supplier like MTM, ensures that your color checks are accurate and repeatable across all production batches.

Optimize Your Lexan Mold Trial Success with MTM

Struggling to source the right Lexan grade or color-matched resin fast for mold trials in China? MTM stocks certified Lexan alternatives and customized solutions locally—no more overseas logistics headaches. Contact us for a rapid quote and level up your polycarbonate project—start your Lexan mold trial with MTM today!

-

Discover how rheology influences material processing and the quality of the final molded part. ↩

-

Understand how this metric helps predict a material’s behavior during the injection molding process. ↩

-

Understanding this char-forming mechanism helps select superior materials for high-temperature and critical safety applications. ↩

-

Understanding this value is key to predicting material deformation, vital for successful engineering design. ↩

-

Understanding this concept helps predict material failure in extreme cold, which is crucial for reliable product design. ↩

-

Understanding this concept helps in selecting plastics that resist degradation during sterilization. ↩

-

Learn how this test measures a material’s resistance to impact, a key factor in product durability. ↩

-

Understanding this helps diagnose internal stress and predict optical performance in transparent parts. ↩

-

Understand how polymer flow direction influences material shrinkage and part geometry. ↩

-

Understand why a color match under one light can fail under another, a crucial factor in product design. ↩