Finding the right plastic resin distributor in the USA can make or break your project timeline. Many engineering teams struggle with unreliable suppliers, delayed shipments, and material inconsistencies that derail critical mold trials and production schedules.

The best plastic resin distributors in the USA combine extensive inventory, certified material traceability, and reliable supply chains to support both domestic molding and international trial coordination, ensuring your projects stay on track.

I’ve worked with engineering teams across different industries at MTM, and I’ve seen how the right distributor partnership can transform project outcomes. This guide covers everything from evaluating supplier credentials to managing cross-border material coordination, giving you the insights needed to make informed decisions.

Ultimate Guide To Choosing Reliable Resin Distributors In The US

Finding the right plastic resin distributors in the USA is a critical step for any project. It’s not just about price. Your choice impacts project timelines, part quality, and overall success. I always tell my clients to look beyond the quote and evaluate the supplier’s entire operation.

Key Decision Factors

When evaluating reliable resin suppliers in America, certain factors are non-negotiable. Supply consistency is paramount. You need a partner who can deliver the exact same material batch after batch. This ensures your final product meets specifications without variation.

Evaluating Supplier Reliability

Ask about their inventory management and supply chain resilience. A transparent distributor will share this information.

| Factor | What to Ask | Why It Matters |

|---|---|---|

| Certifications | "Can you provide ISO 9001 and material-specific certs?" | Guarantees quality and traceability. |

| Lead Time | "What is your standard delivery window for this material?" | Prevents costly delays in your production schedule. |

| Support | "Do you offer technical support for material selection?" | Ensures you choose the best resin for your application. |

Knowing how to choose a resin distributor involves digging deeper into their technical capabilities and customer service. A low price from an unreliable supplier often leads to higher costs down the road from project delays or material failures. I’ve seen this happen too many times.

Beyond the Price Tag

A great distributor acts as a partner. They should provide comprehensive technical data sheets (TDS) and safety data sheets (SDS) without hesitation. Their technical team should be able to help you troubleshoot issues or even suggest alternative materials if needed. This level of support is invaluable.

The Cost of Poor Quality

Choosing a distributor based solely on cost can backfire. Inconsistent material properties, such as variations in Rheology1, can cause major problems during injection molding. This can lead to wasted material, production downtime, and missed deadlines, quickly erasing any initial cost savings. At MTM, we ensure our pre-stocked materials in China are fully certified and consistent for this reason.

| Distributor Choice | Potential Project Outcome |

|---|---|

| Low-Cost, Unverified | Inconsistent part quality, production delays, failed mold trials. |

| Reliable, Certified | Predictable molding performance, on-time project completion, higher quality parts. |

A reliable partner understands the importance of consistency. They invest in quality control to protect their clients’ production processes. This is the kind of partnership that supports long-term success, whether your project is in the US or overseas.

Choosing the right resin distributor is a strategic decision. Focus on reliability, technical support, and certified quality, not just the initial price. This approach protects your project timeline and ensures the final product meets expectations, preventing costly setbacks and delays in production.

Insider Tips For Securing Engineering-Grade Resins In The U.S. Market

Securing the right engineering-grade resin in the U.S. market is a critical task. Your project’s success often depends on materials meeting specific standards, like those from UL or the FDA. The challenge lies in finding reliable plastic resin distributors usa who understand these precise requirements.

Understanding Key Certifications

You must first distinguish between different material grades. A resin suitable for a consumer electronic housing is very different from one used in a medical device. Each has its own compliance demands.

| Certification | Primary Focus | Common Application |

|---|---|---|

| UL Certified | Flammability & Electrical Safety | Electronics, Industrial Parts |

| FDA Grade | Food Contact Safety | Medical Devices, Food Packaging |

Finding The Right Partner

A good distributor does more than just sell material. They should provide technical support and ensure you receive exactly what you specified. This is crucial for maintaining quality and performance.

Navigating the landscape of specialty resins America offers requires diligence. When evaluating an engineering resin distributor USA, you must look beyond their stock list. True partners provide comprehensive support, ensuring material integrity from their warehouse to your production floor.

Vetting Your Distributor

The right supplier relationship is built on trust and verification. A key part of this process is confirming their ability to provide consistent, high-quality materials with complete traceability.

The Importance of Documentation

Always demand a complete set of documents for your material. This includes the Technical Data Sheet (TDS) and safety information. Without these, you cannot verify the properties of the plastic resin for engineering uses you purchased. Based on our work with clients, missing paperwork is a frequent cause of production holds.

Custom Specification Demands

For custom-specified materials, the details matter even more. Properties such as melt flow, tensile strength, and Isotropy2 must be clearly defined and confirmed. A reliable distributor will work with you to ensure these parameters are met.

| Vetting Step | Key Action | Why It Matters |

|---|---|---|

| Request Samples | Test a small batch in your application. | Verifies real-world performance. |

| Check Certifications | Ask for certificates of compliance. | Guarantees regulatory adherence. |

| Review Traceability | Confirm lot numbers on all paperwork. | Ensures material consistency. |

To secure engineering-grade resins, you must diligently vet distributors. Always verify certifications, demand complete documentation, and communicate technical specifications clearly. This proactive approach prevents costly delays and ensures your project’s material integrity from the start.

Best Kept Secrets Of Managing Multi-Country Resin Trials Efficiently

Managing resin trials across different countries, such as the US and China, presents unique challenges. The goal is identical outcomes, but variables often get in the way. It’s not just about shipping a box of pellets; it’s about control and consistency.

The Standardization Challenge

Ensuring the resin used in a China trial is identical to the one specified in the US is the first hurdle. Different regions may have slight variations in formulation, even under the same product code. This can lead to inconsistent trial results.

Logistical Hurdles

Shipping materials internationally introduces delays and high costs. The table below outlines common issues teams face.

| Challenge | Impact on Project |

|---|---|

| Customs Delays | Pushes back trial schedules by weeks |

| High Shipping Costs | Increases overall project budget significantly |

| Material Damage/Loss | Requires re-shipping, causing major delays |

A streamlined process requires a local partner to overcome these logistical nightmares, ensuring your project stays on track.

Harmonizing Material Specifications

True multi-location mold trial coordination goes beyond matching datasheets. A common mistake is assuming that a resin with the same name from different plastic resin distributors usa and Asia will perform identically. Batch-to-batch consistency can vary significantly between production regions.

Beyond the Datasheet

Properties like Viscoelasticity3 are often not fully captured on a standard technical datasheet but heavily influence molding behavior. My team at MTM focuses on sourcing materials that not only match the spec sheet but also the performance profile required for your specific application.

A Smarter Logistical Approach for US-China Projects

Effective US China resin trial support hinges on logistics. Instead of shipping materials from the US, which adds cost and risk, we pre-stock certified equivalent resins in China. This eliminates customs delays and cuts transit time from weeks to days. It provides a reliable local supply chain.

| Logistics Method | Lead Time | Cost Factor | Risk Level |

|---|---|---|---|

| Air Freight from US | 1-2 Weeks | High | Medium |

| Sea Freight from US | 4-6 Weeks | Low | Medium |

| Local MTM Supply | 1-3 Days | Minimal | Low |

This localized model ensures your mold trial starts on schedule, with the right material ready when your tool is.

Successful multi-country resin trials depend on two factors: meticulous material harmonization and smart, localized logistics. Overlooking either can lead to delays and inconsistent results. A local partner can bridge the gap, ensuring efficiency and project success.

How To Compare OEM-Approved Vs Equivalent Resin Grades In The U.S.

Choosing between an OEM-approved resin and an equivalent grade in the U.S. is a critical decision. It directly impacts your project’s timeline, budget, and final product quality. The right choice depends heavily on your specific application and risk tolerance. Understanding the differences is the first step.

The OEM-Approved Standard

OEM-approved grades are materials officially specified by the original equipment manufacturer. This ensures complete compliance with design specifications and performance requirements. However, sourcing these materials, especially for trials in China, can introduce delays and high shipping costs.

The Equivalent Grade Alternative

Equivalent grades offer a cost-effective and readily available alternative. They are designed to match the key performance properties of the OEM material. The challenge lies in rigorously validating this equivalency to avoid any performance gaps in critical applications.

| Feature | OEM-Approved Resin | Equivalent Resin Grade |

|---|---|---|

| Approval | Pre-approved by OEM | Requires validation |

| Availability | Can be limited | Generally higher |

| Cost | Typically higher | More cost-effective |

| Lead Time | Often longer | Shorter, especially locally |

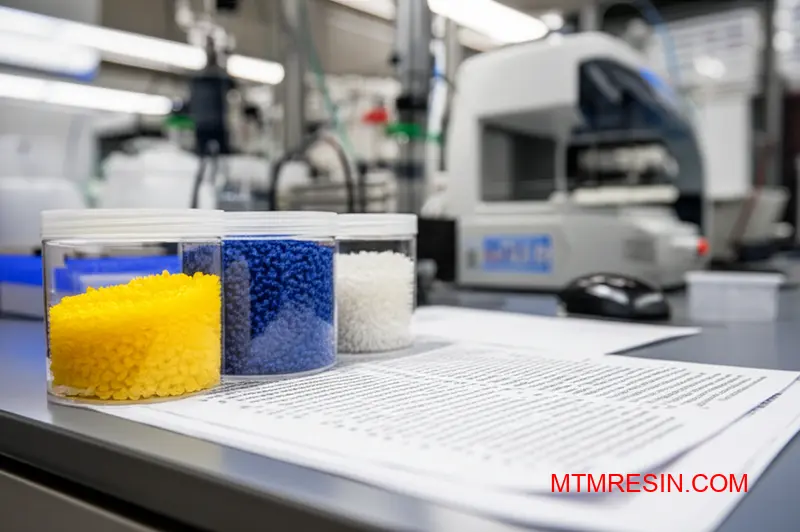

Validating resin equivalency is more than just comparing datasheets. It’s a technical process to ensure the alternative material performs identically in your application. As a reliable equivalent plastic grades supplier, we always begin with a thorough data review before any physical testing.

Matching Critical Properties

For critical applications, we focus on matching key performance indicators beyond basic specs. Our process ensures that resin equivalents for brand approval meet stringent requirements. We have found that this level of detail is often overlooked by standard plastic resin distributors usa.

Key Validation Steps

- Datasheet Comparison: We start by comparing Melt Flow Index (MFI), density, tensile strength, and heat deflection temperature (HDT).

- Performance Testing: Lab tests may include impact strength or chemical resistance, depending on the part’s function.

- Processing Window: We verify that the equivalent resin processes similarly to the OEM material. This avoids surprises during mold trials.

The material’s internal structure, its Polymer morphology4, can influence these properties. This is why a simple data match is not always enough for demanding applications that require specific performance characteristics.

| Property | OEM Grade (Example) | Equivalent Grade (Target) | Status |

|---|---|---|---|

| MFI (g/10min) | 10.5 | 10.2 | Match |

| Tensile Strength (MPa) | 60 | 61 | Match |

| HDT @ 0.45 MPa (°C) | 125 | 124 | Match |

| Notched Izod (J/m) | 50 | 48 | Match |

Choosing between OEM and equivalent resins involves a trade-off. While OEM grades guarantee compliance, equivalents offer flexibility and cost savings. Proper validation by an experienced partner is essential to ensure the equivalent material meets all critical performance requirements for your project.

The Hidden Cost Of International Resin Shipments vs. U.S. Local Suppliers

Choosing between an international resin supplier and a local one seems simple. Many focus only on the per-kilogram price. However, this overlooks the complex web of hidden costs that can derail a project budget and timeline, especially for critical mold trials in China.

Initial Cost Assessment

At first glance, international suppliers may offer a lower unit price. But this figure is just the starting point. You must factor in shipping, which can be substantial. Local U.S. suppliers, on the other hand, build these logistics into a more predictable, albeit higher, initial price.

Comparing Upfront Expenses

A direct comparison reveals the immediate trade-offs. The decision isn’t just about the material; it’s about the entire supply chain.

| Cost Factor | International Supplier | U.S. Local Supplier |

|---|---|---|

| Unit Price | Often Lower | Typically Higher |

| Shipping | High & Variable | Lower & Predictable |

| Lead Time | 4-8 Weeks | 1-5 Days |

| Initial Quote | Misleadingly Low | More Inclusive |

This initial analysis often misses the most significant expenses, which surface only after the shipment has begun its long journey.

The true cost of importing resin goes far beyond the freight invoice. When comparing ‘local vs overseas resin,’ you must consider variables that don’t appear on the initial quote. These factors can inflate your final expenditure significantly and introduce unacceptable project delays.

Unpacking the Hidden Costs

Customs clearance is a major uncertainty. A simple paperwork error can leave your materials stuck at port for weeks. This delay directly impacts your mold trial schedule, creating a domino effect of lost time and opportunity. The ‘resin import costs USA’ must include potential demurrage fees.

The Price of Waiting

We’ve seen projects delayed by a month just waiting for resin. That’s a month of paying for tooling modifications, engineering time, and facility overhead without progress. The opportunity cost of a delayed product launch can often exceed the entire cost of the material itself.

| Hidden Factor | International Shipment | U.S. Local Supplier |

|---|---|---|

| Customs Risk | High (Delays, Fees) | None (Domestic) |

| Communication | Time Zone & Language Barriers | Same Day, Clear |

| Opportunity Cost | High (Project Delays) | Low |

| Total Landed Cost5 | Unpredictable & High | Predictable & Lower |

This is why many companies now prefer working with U.S.-based plastic resin distributors usa, even for trials in China. A partner like MTM bridges this gap by stocking materials locally in China, eliminating these risks entirely.

Choosing a supplier requires looking past the unit price. International shipments carry hidden costs in delays, customs, and lost opportunities. Reliable local plastic resin distributors usa offer predictability and control, ensuring your project timeline and budget remain intact.

Complete Comparison Of Leading Plastic Resin Distributors In The USA

Choosing the right partner among the many plastic resin distributors in the USA is a critical decision. Your choice impacts project timelines, costs, and final product quality. I’ve found that no single supplier is best for every need; it’s about matching their strengths to your project requirements.

Key Comparison Metrics

The best resin vendors in America often differ in their core offerings. Large national players may offer competitive pricing on commodity resins but have longer lead times. Smaller, specialized distributors might provide niche materials and expert support at a premium.

| Feature | National Distributors | Specialized Distributors |

|---|---|---|

| Pricing | Highly competitive on bulk orders | Higher, but offers value-adds |

| Lead Times | Can be longer; centralized inventory | Often shorter for specific materials |

| Support | Generalist support | Expert, application-specific advice |

This initial resin supplier comparison helps frame the decision-making process based on what you value most: cost savings or specialized service and speed.

A Deeper Look at Supplier Capabilities

When evaluating top plastic resin distributors in the USA, we must look beyond price. The scope of their inventory is a major factor. Some focus on commodity polymers like PP and PE, while others specialize in high-performance engineering resins for automotive or medical applications.

Specializations and Stock Scope

A distributor’s specialization often dictates their entire operational model. A supplier focused on medical-grade materials will have rigorous quality control and documentation processes. This ensures complete Material Traceability6, which is non-negotiable in regulated industries. Conversely, a distributor for consumer goods may prioritize cost and volume over extensive certification.

| Distributor Type | Primary Focus | Ideal For |

|---|---|---|

| Commodity Focused | High-volume, standard resins | Packaging, consumer goods |

| Engineering Grade | High-performance materials | Automotive, electronics |

| Medical Grade | Biocompatible, certified resins | Healthcare devices, pharma |

This is where context matters. While these US-based distributors are excellent for domestic production, they often struggle to support international projects efficiently. For mold trials in China, my team at MTM pre-stocks specified resins locally, eliminating the cross-border shipping delays and costs you’d face with a US supplier.

Choosing among plastic resin distributors in the USA requires a clear understanding of your project’s needs. Balancing price, inventory scope, and lead time is key. The best vendor is the one whose specialization aligns perfectly with your application’s technical and logistical requirements.

What Every Procurement Manager Should Know About Resin MOQ And Pricing

As a procurement manager, you constantly deal with Minimum Order Quantities (MOQ) and pricing. These figures are not arbitrary. They are deeply tied to the manufacturer’s production efficiency and the distributor’s logistics model. Understanding this is your first step toward better negotiations.

The Basics of MOQ

MOQ is the smallest amount of resin a supplier will sell in a single order. This is often dictated by packaging sizes, like a 25 kg bag or a full pallet. For specialized materials, the MOQ might reflect a minimum production batch size from the manufacturer.

Volume Discounts Explained

Suppliers reward larger orders with lower per-unit prices. This is a simple concept, but the tiers can vary. Knowing these breakpoints is crucial for optimizing your budget. Here’s a typical structure:

| Order Volume (kg) | Price per kg (Example) |

|---|---|

| 25 – 500 | Base Price |

| 501 – 1,000 | 5% Discount |

| 1,001 – 5,000 | 10% Discount |

| 5,000+ | 15%+ Discount |

Understanding pricing mechanics goes beyond the list price. Many factors influence the final cost you pay. It’s important to look at the complete picture to avoid surprises and find real savings. At MTM, we guide clients through these complexities daily.

Breaking Down Pricing Structures

The price you see often includes more than just the material. It can bundle logistics, handling, and other fees. When negotiating, ask for a cost breakdown. This transparency helps identify where you can save. Sometimes, a higher material price from a local supplier is cheaper overall than importing.

Strategic Negotiation Points

Effective plastic resin price negotiation involves more than asking for a discount. It’s about creating value. Propose blanket orders or scheduled releases to help the supplier with their forecasting. This can often unlock better bulk resin purchase terms than a one-time large purchase.

This strategy differs from what you might see with some plastic resin distributors usa, who may have rigid tier systems. We find flexibility is key. Calculating the Economic Order Quantity7 is also a powerful tool. It helps you find the sweet spot between purchase price, order frequency, and inventory costs.

| Negotiation Tactic | Potential Outcome |

|---|---|

| Blanket Purchase Order | Locks in pricing, ensures supply |

| Scheduled Releases | Improves cash flow, reduces inventory |

| Consignment Stock | Pay only for what you use |

| Asking for Cost Breakdown | Identifies hidden fees and savings |

Mastering MOQ and pricing is key for efficient procurement. Understanding volume discounts and negotiation tactics allows you to optimize costs and ensure a stable material supply for your projects, especially during critical mold trial phases.

Why Material Traceability Matters For Your Resin Supply Chain

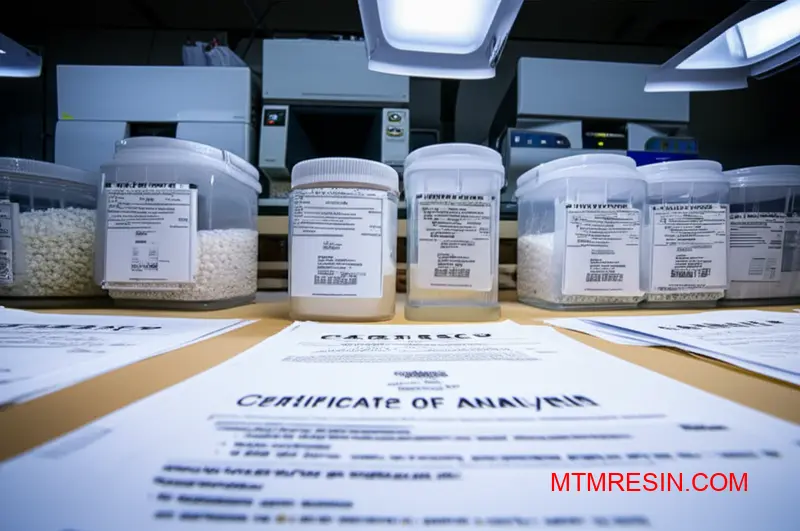

In our industry, a label on a bag of resin isn’t enough. True material traceability comes down to two key documents: the batch number and the Certificate of Analysis (COA). These elements are fundamental for quality control and risk management in any serious manufacturing project.

The Power of Batch Tracking

A batch number connects a specific bag of resin directly to its production run. This allows us to trace its history, including the manufacturing date and specific equipment used. If an issue arises, we can isolate the problem quickly without halting all production.

What a COA Guarantees

The COA for plastic resin is its official report card. It confirms that the material meets the technical data sheet’s specifications. It provides tested values for properties like melt flow, density, and tensile strength, giving you verifiable proof of quality.

| Feature | Traceable Resin | Untraceable Resin |

|---|---|---|

| Verification | COA confirms specs | Relies on seller’s word |

| Batch ID | Specific production run | Unknown origin |

| Risk | Low; easy to recall | High; impossible to isolate |

| Compliance | Meets industry standards | Fails most audits |

For industries like medical, automotive, or food contact, traceability is not just good practice—it’s a strict requirement. A single component failure can trigger massive recalls, legal issues, and severe damage to a brand’s reputation. Certified resin tracking USA standards help prevent these outcomes.

Compliance and Risk Mitigation

In regulated sectors, every material must have a documented history. This ensures that it meets safety and performance standards, such as FDA or ISO certifications. Without a clear trail from the manufacturer, your final product is non-compliant and cannot be sold in most markets.

The Distributor’s Role in a Secure Supply Chain

This is where your choice of supplier becomes critical. Reputable plastic resin distributors usa are essential for maintaining the material’s Chain of Custody8. They ensure that the documentation travels with the physical product, guaranteeing that what you ordered is exactly what you receive. At MTM, we stake our reputation on this promise for every mold trial.

| Industry | Key Requirement | Consequence of Failure |

|---|---|---|

| Medical | Biocompatibility, Sterilization | Patient safety risk, FDA recall |

| Automotive | Heat Resistance, Impact Strength | Component failure, vehicle recall |

| Food Contact | FDA/EU Compliance | Contamination, public health issues |

In essence, batch tracking and COAs are your supply chain’s insurance policy. They ensure material integrity, support regulatory compliance, and protect your project from costly failures. This level of resin traceability is a baseline requirement for professional operations and quality assurance.

Expert Tips For Selecting China-Compatible Resin From U.S. Distributors

Why Direct Equivalents Are Rare

Matching U.S.-approved resins to China-molded equivalents is a common challenge. Engineers often find that a grade available from U.S. plastic resin distributors isn’t stocked in China. This creates a need to find a suitable, locally available substitute that performs identically.

Key Performance Indicators

The goal is achieving resin compatibility between China and the USA. This means looking beyond the datasheet. We focus on key performance indicators that affect molding, such as melt flow, shrinkage, and mechanical properties. These are critical for matching resin for China tools.

| Parameter | U.S. Grade | China Equivalent Target |

|---|---|---|

| Melt Flow Index (g/10min) | 22 | 21-23 |

| Tensile Strength (MPa) | 60 | 58-62 |

| Shrinkage (%) | 0.5-0.7 | 0.5-0.7 |

Beyond the Datasheet: Practical Considerations

Technical datasheets provide a starting point for comparing cross-country plastic grades. However, they don’t tell the whole story. Processing conditions, color matching, and even the Hygroscopic Nature9 of the material can introduce significant variations that impact the final part’s quality.

A resin might seem identical on paper but behave differently in a Chinese molding environment due to humidity or drying procedures. I’ve seen projects delayed because a substitute material required different pre-processing than the original specified by U.S. engineers.

Verification and Testing Process

This is where we at MTM provide value. We help clients navigate these nuances. We don’t just find a datasheet match; we leverage our local supply chain to source and test potential equivalents. This ensures functional consistency and de-risks the mold trial process.

| Verification Step | Description | Importance |

|---|---|---|

| Datasheet Analysis | Compare key specs (MFI, HDT, etc.). | Initial screening for candidates. |

| Sample Testing | Mold small samples for physical tests. | Confirms real-world performance. |

| Process Validation | Run trials with production settings. | Ensures compatibility with tooling. |

Many plastic resin distributors in the USA lack the on-the-ground presence in China to perform this level of validation. Our local stock and expertise bridge that gap, ensuring a smooth transition from U.S. specification to Chinese production without costly delays.

Selecting a China-compatible resin requires more than a datasheet comparison. Practical factors like processing conditions and local availability are critical. Partnering with a local expert ensures that your chosen equivalent performs reliably in your China-based tools, preventing costly project delays.

Choose MTM For Stress-Free US-China Resin Trials & Supply

Streamline your mold trials and resin sourcing in China with MTM! Skip the shipping delays and import hassles—MTM stocks OEM-approved, engineering, and specialty resins locally in China. Contact us now for a quote and get the exact plastic resins you need, fast and reliably, for your cross-border projects.

-

Understanding this helps predict material flow during molding, preventing costly production errors and ensuring part consistency. ↩

-

Understanding this property helps predict material performance under stress, which is crucial for part design. ↩

-

Explore how this material property impacts resin flow and final part performance. ↩

-

Learn how a material’s internal structure dictates its real-world strength, flexibility, and durability. ↩

-

Understanding this helps calculate the total expense of bringing a product to your facility. ↩

-

Understanding this ensures material consistency and compliance, which is critical in quality control. ↩

-

Learn how this formula balances inventory costs against order costs to optimize your purchasing strategy. ↩

-

Learn how this concept ensures the integrity and history of materials from source to final use. ↩

-

Understanding this property helps you prevent material defects caused by moisture during the molding process in different climates. ↩