When your mold trial depends on the exact Ultradur grade specified in your design, sourcing delays can derail entire project timelines. Engineers face constant pressure to balance performance requirements with material availability, especially when dealing with BASF’s extensive PBT portfolio where one wrong grade selection can compromise dimensional stability or flame retardancy.

Ultradur PBT offers superior dimensional stability and chemical resistance compared to PA66, with specific grades like B 4300 G6 providing 30% glass fiber reinforcement for automotive connectors, while HR series delivers hydrolysis resistance for harsh environments.

Working with engineering teams across different industries, I’ve noticed that Ultradur selection often becomes overwhelming due to the sheer number of variants available. This guide breaks down the decision-making process, from understanding grade hierarchies to optimizing your supply chain in China.

The Ultradur name covers a wide family of PBT resins. Understanding the hierarchy is key to choosing the right grade. It’s not just one material, but a portfolio designed for different engineering needs. We can break it down into three main categories for clarity.

Standard Unreinforced Grades

These are the foundational Ultradur grades. They offer good flow characteristics and surface finish. Think of them for applications where high mechanical strength is not the primary requirement, such as aesthetic housings or simple electrical connectors where insulation is the main goal.

Glass-Fiber Reinforced Series

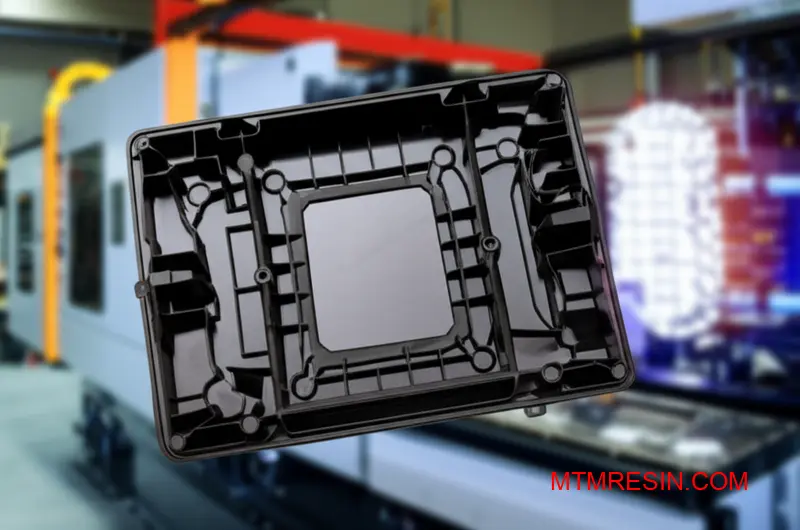

When you need stiffness and strength, you turn to the glass-fiber reinforced series. The addition of glass fibers dramatically improves mechanical properties. This makes them suitable for structural components that must withstand significant loads, like automotive parts or industrial machinery components.

| Grade Type | Primary Benefit | Common Use Case |

|---|---|---|

| Standard | Excellent Flow & Finish | Electrical Housings |

| Reinforced | High Strength & Stiffness | Structural Automotive Parts |

| Specialty | Specific Performance | Connectors with FR needs |

Specialty Modifications

This category includes materials like flame-retardant resins. These are engineered for applications where safety and compliance with standards like UL 94 are critical. You will find these specific Ultradur grades in consumer electronics and electrical systems.

Choosing the right Ultradur series goes beyond a datasheet. It’s about matching the material’s core strengths to your project’s specific demands. The choice between a standard, reinforced, or specialty grade has significant implications for both performance and processing.

Mapping Requirements to the Right Series

Engineers often ask me which Ultradur PBT grade is best. The answer starts with the application’s primary function. Is the part a structural component under constant load, or is it an enclosure for sensitive electronics? For structural parts, a glass-fiber reinforced PBT is almost always the starting point. The fiber percentage dictates the final stiffness.

Impact on Processing Parameters

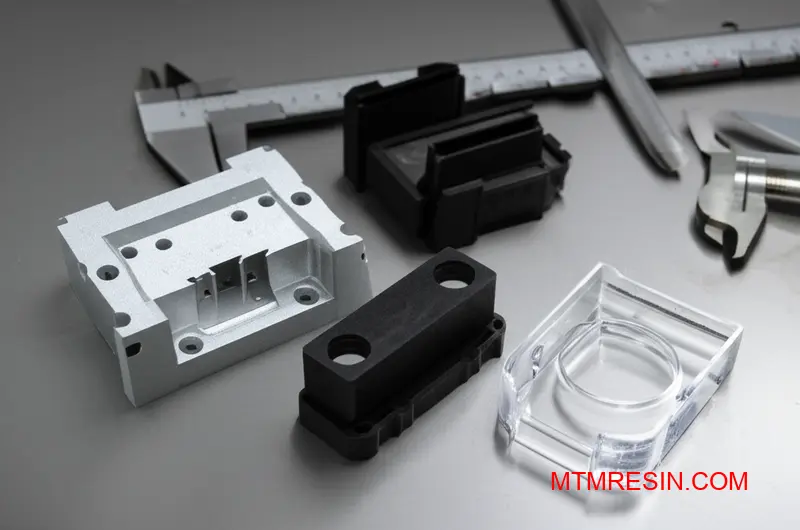

A critical factor we see in mold trials is how reinforcement affects processing. Adding glass fibers increases the material’s Viscosity1, which often requires adjustments to injection pressure and temperature. Unreinforced grades flow more easily, filling complex, thin-walled parts with less effort. At MTM, we supply these different grades so teams in China can validate their mold and process with the exact material.

| Requirement | Recommended Ultradur Series | Key Consideration |

|---|---|---|

| High Stiffness | Glass-Fiber Reinforced | Higher injection pressure needed |

| Electrical Safety | Flame Retardant | May affect colorability |

| Complex Geometry | Standard Unreinforced | Excellent mold-filling ability |

Flame retardant resins introduce another variable. While they provide essential safety, the additives can sometimes influence mechanical properties or processing behavior. This is why a proper mold trial is so important.

Choosing the right Ultradur grade means balancing mechanical needs, safety requirements, and processability. Understanding the fundamental differences between standard, reinforced, and flame-retardant series is the first step to selecting the ideal material for your specific application’s success.

Reinforced Grades Analysis: When to Specify Ultradur B 4300 G6 vs. G4

When selecting a reinforced PBT, the choice often comes down to Ultradur B 4300 G6 and G4. The key difference is the glass fiber content. G6 contains 30% glass fiber, while G4 has 20%. This seemingly small change has a major impact on mechanical properties.

Key Performance Differences

The higher glass fiber content in G6 directly translates to increased stiffness and strength. It’s the go-to option for parts that must resist deformation under load. G4, while still robust, offers slightly better flow and a different cost-performance balance.

At a Glance: G6 vs. G4

| Grade | Glass Fiber (%) | Primary Benefit |

|---|---|---|

| Ultradur B 4300 G6 | 30% | Maximum Stiffness & Strength |

| Ultradur B 4300 G4 | 20% | Balanced Performance |

This initial comparison helps frame the decision for your specific application needs.

Let’s dive deeper into the specifics. The 30% glass fiber in Ultradur B 4300 G6, often labeled as PBT GF30, makes it significantly stiffer than the G4 grade. Our internal test data shows a noticeable increase in tensile modulus, which is critical for structural components.

Tensile Strength and Stiffness Comparison

For applications like automotive connectors, high stiffness is essential to prevent pin deflection and ensure reliable connections. The G6 grade provides that extra rigidity. The G4 is still an excellent material but is better suited for housings or covers where the mechanical loads are less demanding. The direction of the fibers also affects strength, a property known as Anisotropy2.

Application Suitability

When clients in China need to run mold trials for demanding parts, I often recommend starting with Ultradur B 4300 G6. Having both grades ready at MTM allows for quick validation. You can test the more robust option first and then evaluate if G4 meets requirements.

| Property | Ultradur B 4300 G4 | Ultradur B 4300 G6 |

|---|---|---|

| Tensile Modulus (MPa) | ~8000 | ~10000 |

| Tensile Strength (MPa) | ~115 | ~130 |

| Common Use Case | Housings, Covers | Structural Connectors, Brackets |

Choosing between Ultradur B 4300 G6 and G4 depends on the mechanical load. G6 provides superior stiffness for demanding applications, while G4 offers a balanced profile. Making the right choice is crucial for a successful mold trial and end-product performance.

Combating Hydrolysis: Selecting Ultradur HR Grades for Automotive Environments

In automotive design, components are constantly exposed to harsh conditions. Heat, moisture, and chemical agents create an environment where standard plastics can degrade quickly. This degradation often leads to premature part failure, a critical issue for safety and reliability.

The Challenge of Modern Automotive Electronics

Modern vehicles rely heavily on electronic sensors and control units. These components are frequently located in the engine bay or underbody, where they face extreme temperature fluctuations and high humidity. Choosing the right material is not just a design choice; it’s essential for long-term performance.

Why Standard PBT Isn’t Always Enough

Standard Polybutylene Terephthalate (PBT) is a great material, but it has a known weakness: hydrolysis. When exposed to moisture at high temperatures, the polymer chains break down, causing the material to lose its mechanical strength and become brittle. This can lead to system failures.

For critical automotive applications, we must move beyond standard grades. This is where specialized materials become essential. BASF’s Ultradur HR series was developed specifically to address the challenge of polymer degradation in demanding environments.

The Advantage of Ultradur HR Grades

The ‘HR’ in Ultradur HR stands for Hydrolysis Resistant. These grades are chemically modified to withstand the damaging effects of hydrolysis3 far better than standard PBT. This enhanced stability is crucial for sensors, connectors, and control unit housings that need to function flawlessly for years.

Meeting Automotive Standards

Automotive manufacturers rely on rigorous testing standards like the USO (USCAR) specifications to validate component durability. Ultradur HR grades are designed to pass these demanding tests, which simulate years of exposure to extreme heat and humidity cycles. Our test result comparisons confirm their superior performance.

| Property | Standard PBT | Ultradur B4330 G6 HR |

|---|---|---|

| Tensile Strength after 1000h | Significant Drop | High Retention |

| Impact Strength after 1000h | Brittle Failure | Retains Toughness |

| USCAR Class Rating | Class 1/2 | Class 3/4 |

At MTM, we often guide clients toward Ultradur HR grades for their mold trials when reliability is paramount. Having these materials pre-stocked in China means trials aren’t delayed waiting for a shipment of specialized resin from overseas.

Ultradur HR grades provide superior hydrolysis resistance, making them ideal for automotive sensors and control units in harsh environments. This material choice prevents premature part failure and ensures components meet stringent industry standards like USCAR testing, securing long-term reliability.

Dimensional Stability Criticals: Utilizing Ultradur S 4090 for Low Warpage

The PBT Warpage Challenge

Standard PBT is a fantastic material, but its tendency to warp can be a major headache. This is especially true for large, flat components where maintaining dimensional stability is critical. This issue often stems from non-uniform shrinkage during the cooling process after injection molding.

Introducing Ultradur S 4090

To address this, specialized grades like BASF’s Ultradur S 4090 were developed. This material is a PBT+ASA blend engineered specifically for low warpage. It offers a significant improvement in dimensional control without sacrificing the core benefits of PBT, making it ideal for demanding applications.

| Feature | Standard PBT | Ultradur S 4090 |

|---|---|---|

| Primary Use | General Purpose | Low-Warpage Parts |

| Warpage Tendency | Moderate to High | Very Low |

| Part Geometry | Less sensitive | Ideal for flat, large parts |

Why Standard PBT Warps

The primary cause of warpage in glass-fiber-reinforced PBT is differential shrinkage. Fibers align differently in the flow direction versus the cross-flow direction. This creates internal stresses as the part cools, leading to distortion. It’s a fundamental material behavior that becomes more pronounced in larger parts.

The Low-Warpage Solution

The Ultradur S series, including Ultradur S 4090, modifies the polymer matrix. By blending PBT with materials like ASA or PET, the blend achieves more isotropic, or uniform, shrinkage. This reduces the internal stresses caused by fiber orientation and significantly improves the part’s final flatness and dimensional accuracy.

Shrinkage Rate Comparison

Based on our comparative tests, the difference is clear. The more balanced shrinkage of low-warp grades is key. This modified Crystallinity4 behavior helps ensure that the part conforms to the mold cavity with much higher precision, saving time and costs on tool adjustments.

| Material Grade | Shrinkage (Flow) | Shrinkage (Cross-Flow) |

|---|---|---|

| Standard GF30 PBT | 0.2% – 0.5% | 0.6% – 1.0% |

| Ultradur S 4090 G6 | 0.3% – 0.5% | 0.4% – 0.6% |

At MTM, we stock materials like Ultradur S 4090 in China, ensuring you have a quick solution for warpage issues during mold trials without waiting for overseas shipments.

Ultradur S 4090 provides exceptional dimensional stability by minimizing differential shrinkage, a common issue in standard PBT. This makes it a reliable choice for large, flat components where precision is paramount, preventing costly mold rework and project delays.

High-Flow Solutions: Reducing Cycle Times with Ultradur High Speed Series

In injection molding, efficiency is everything. The Ultradur High Speed series offers a direct path to reducing cycle times, especially for complex or thin-walled components. This high flow PBT material fills molds faster and at lower pressures, which translates to significant production gains.

The Advantage of Speed

Faster cycle times mean more parts per hour. For procurement teams, this directly impacts the cost per part. Lowering the injection pressure also reduces wear on molds and machinery, which is a long-term cost saving. It’s a clear win for overall manufacturing efficiency.

Key Performance Indicators

| Feature | Standard PBT | Ultradur High Speed |

|---|---|---|

| Relative Cycle Time | 100% | 70-80% |

| Required Injection Pressure | High | Low-Medium |

| Ideal Wall Thickness | >1.5 mm | <1.5 mm |

| Energy Consumption | Standard | Reduced |

This improved flowability enables designs that were previously challenging with standard PBT materials.

Deeper Dive into Molding Efficiency

The primary benefit of the Ultradur High Speed series lies in its modified rheology. The material is engineered to flow more easily in its molten state. This allows it to travel through intricate mold channels and fill thin sections without premature freezing or requiring excessive pressure.

Rheological Benefits in Practice

This characteristic is crucial for modern electronics and automotive components, where designs demand thinner walls to save weight and space. We often see clients struggle with standard materials causing short shots or high stress in these applications. The high flow nature of Ultradur directly solves these common molding defects. Based on tests with our clients, a smoother flow also leads to a better surface finish, reducing the need for secondary processing. Measuring the Melt Flow Rate5 is key to quantifying this advantage.

Cost Implications for Project Managers

| Parameter | Impact of Ultradur High Speed | Financial Outcome |

|---|---|---|

| Cycle Time | Reduced by up to 30% | Lower cost per part |

| Energy Usage | Lower molding pressures | Reduced operational expenses |

| Scrap Rate | Fewer flow-related defects | Less material waste |

| Tooling Wear | Reduced stress on molds | Longer tool life, lower maintenance |

At MTM, we stock these high-performance Ultradur grades in China. This means your team can test and validate these cycle time reductions without waiting for international shipments, keeping your project on schedule.

Ultradur High Speed grades significantly boost manufacturing efficiency by improving flowability. This leads to faster cycle times, lower injection pressures, and reduced cost per part, which is especially valuable for producing thin-walled components.

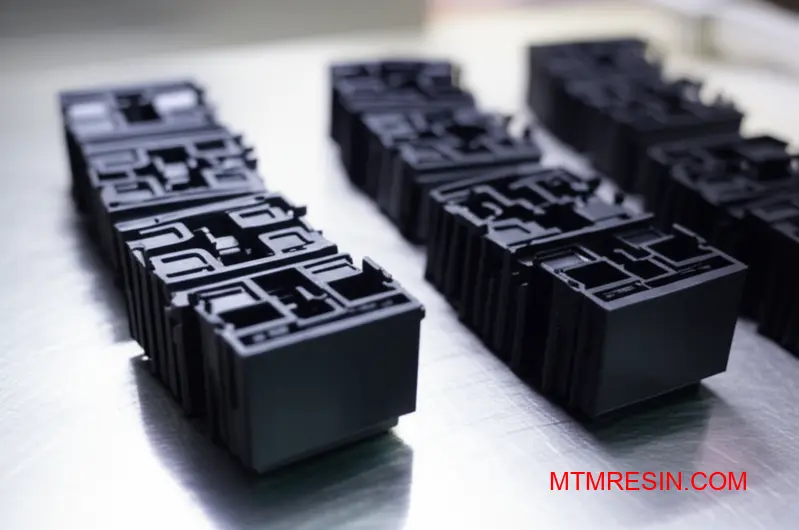

Flame Retardancy compliance: Examining Ultradur B 4406 and B 4450

In electronics, flame retardancy is not just a feature; it is a necessity for safety. Achieving a UL94 V-0 rating is a critical benchmark for compliance. This standard ensures a material self-extinguishes quickly after flame exposure, preventing fire propagation in sensitive components.

Key Ultradur FR Grades

Two prominent choices are Ultradur B 4406 and B 4450. Both are PBT grades designed for demanding electrical applications. They meet compliance in different ways, making it vital to understand their core distinctions before your next mold trial in China.

| Feature | Ultradur B 4406 G6 | Ultradur B 4450 G5 |

|---|---|---|

| Reinforcement | 30% Glass Fiber | 25% Glass Fiber |

| Key Benefit | Halogenated FR System | Halogen-Free FR System |

| Primary Use | Connectors, Housings | Eco-conscious Designs |

This comparison helps frame the decision-making for engineers and project managers.

Halogenated vs. Halogen-Free Systems

The main difference between these two Ultradur grades is their flame-retardant chemistry. Ultradur B 4406 uses a traditional halogenated system, which is highly effective and well-established. However, environmental regulations increasingly favor halogen-free alternatives due to concerns about combustion byproducts.

Ultradur B 4450 meets this demand with a halogen-free package. It is a preferred choice for companies with strict environmental goals or products targeting markets with stringent regulations. This is a critical factor for many electronic components today.

The Impact on Mechanical Properties

Adding flame retardants always involves trade-offs. These additives can interfere with the polymer matrix, often leading to a slight reduction in mechanical performance compared to non-FR grades. The chemistry works by disrupting the material’s Pyrolysis6 cycle during combustion, which can affect its physical state.

Based on our analysis, while both materials offer excellent stiffness, some properties are altered.

| Property | Standard 30% GF PBT | Ultradur B 4406 G6 (FR) |

|---|---|---|

| Tensile Modulus | High | Very High (Slight Increase) |

| Impact Strength | Good | Slightly Reduced |

| Flowability | Excellent | Good |

At MTM, we help clients navigate these nuances. Having both Ultradur B 4406 and B 4450 pre-stocked in China allows for rapid mold trials to validate which material’s performance profile is acceptable for your specific design.

Choosing between Ultradur B 4406 and B 4450 involves balancing UL94 V-0 compliance, regulations, and mechanical performance. The decision rests on whether a proven halogenated system or a modern halogen-free alternative better suits your project’s technical and environmental goals.

Mechanical Property Profile: Stiffness, Toughness, and Creep Resistance

When engineers review a technical datasheet, they often focus on two numbers: Young’s Modulus and impact strength. These figures are crucial starting points. Young’s Modulus tells you about the material’s stiffness, or its resistance to being deformed elastically. A higher number means a stiffer material.

Reading Key Stiffness and Toughness Metrics

Toughness, often measured by Charpy or Izod impact tests, indicates a material’s ability to absorb energy and plastically deform without fracturing. It’s about how well a part can handle a sudden blow. Choosing the right material requires balancing these two properties.

| Property | What It Measures | High Value Means |

|---|---|---|

| Young’s Modulus | Stiffness, resistance to elastic deformation | More rigid |

| Charpy Impact Strength | Toughness, energy absorption before fracture | More durable |

For materials like BASF’s Ultradur PBT, datasheets provide a clear picture of its initial performance.

However, short-term data doesn’t tell the whole story. A critical mistake is ignoring how a material behaves over months or years under a constant load. This is where we must consider creep resistance, a key factor for long-term dimensional stability.

The Overlooked Factor: Long-Term Creep

Creep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stresses. For a plastic part that will be under constant tension or compression, high initial stiffness means little if the part slowly deforms over time.

Why Creep Matters in Application

Think about a snap-fit connector or a housing that supports an internal component. If the material creeps, the connection can loosen, or the housing could warp, leading to product failure. We must analyze long-term creep data, not just the initial modulus. The underlying material science, like Dislocation Climb7, explains why this occurs.

| Factor | Influence on Creep | Design Consideration |

|---|---|---|

| Temperature | Higher temps accelerate creep | Operating environment analysis |

| Load | Higher stress increases creep rate | Stress distribution in the part |

| Material Grade | Fillers (e.g., glass fiber) reduce creep | Select reinforced grades like Ultradur |

At MTM, we guide clients through this data for their mold trials, ensuring the chosen material withstands real-world conditions.

Understanding datasheet values for stiffness and toughness is essential. But for long-term reliability, you must also evaluate creep resistance. This ensures your part performs not just on day one, but throughout its intended service life, especially when using high-performance PBT like Ultradur.

Comparative Analysis: Ultradur PBT vs. PA66 and PET for Structural Parts

Choosing the right material for structural parts involves a critical trade-off between performance, processability, and cost. Ultradur PBT, PA66, and PET are all strong candidates, but their distinct properties make them suitable for different applications. The key is understanding their behavior under real-world conditions.

Key Performance Metrics

When I assist engineers, we often focus on moisture absorption first. This single factor heavily influences a part’s long-term dimensional stability and mechanical strength. A material that swells or weakens in humid environments can lead to component failure.

| Property | Ultradur PBT | PA66 (Nylon) | PET |

|---|---|---|---|

| Moisture Absorption | Very Low | High | Low |

| Dimensional Stability | Excellent | Fair | Good |

| Processing Ease | Excellent | Good | Fair |

This comparison shows why Ultradur often becomes the preferred choice for applications demanding high precision and reliability over the product’s lifespan.

A Deeper Dive into Material Behavior

The spec sheet only tells part of the story. In practice, the high moisture absorption of PA66 means its mechanical properties can change significantly between a dry, as-molded state and its condition after exposure to ambient humidity. This can be a major issue for parts with tight tolerances.

Cost Beyond the Price Per Kilogram

While PA66 may sometimes have a lower initial cost, the total cost of production can be higher. Its sensitivity to moisture requires careful pre-drying and can lead to a higher scrap rate from warping. Ultradur PBT’s stability often translates to more consistent processing and fewer rejected parts.

Processing and Long-Term Performance

PET offers excellent strength but demands higher processing temperatures and meticulous drying, increasing energy costs. For long-term structural integrity, we also must consider factors like Creep8, which is the tendency of a material to deform permanently under constant load.

| Feature | Ultradur PBT | PA66 (Nylon) | PET |

|---|---|---|---|

| Required Drying | Minimal | Essential | Essential & Critical |

| Typical Melt Temp (°C) | 225-250 | 260-290 | 260-280 |

| Tooling Corrosion | Low Risk | Low Risk | Potential Risk |

At MTM, we supply these materials for mold trials, allowing teams to validate these processing differences firsthand before committing to mass production.

For structural parts requiring precision and reliability, Ultradur PBT provides an excellent balance of dimensional stability, low moisture absorption, and processability. While PA66 offers toughness and PET provides high strength, their environmental and processing sensitivities must be carefully managed.

Supply Chain Realities: Availability of Ultradur Grades in the Chinese Market

Sourcing specific German-spec Ultradur grades in China can be a major headache. The primary issue is that many specialized grades are not consistently stocked locally. This creates significant delays and uncertainty for projects that rely on precise material specifications for mold trials.

The Sourcing Challenge

Project managers often face a tough choice: wait weeks for an import or consider a local alternative. This decision directly impacts timelines and budgets. The core problem is a fragmented network of Ultradur distributors, leading to inconsistent resin availability in China.

Common Ultradur Grades vs. Availability

The table below shows what we typically see in the market. Standard grades are easier to find, but high-performance or specialized versions often require sourcing from overseas, creating a material shortage for urgent trials.

| Grade Category | China Market Availability | Common Challenge |

|---|---|---|

| Standard Injection Molding | Generally Available | Minimum Order Quantities (MOQs) |

| High-Flow / Low-Warp | Limited Stock | Long Import Lead Times |

| Glass-Fiber Reinforced | Inconsistent | Batch-to-Batch Variations |

| Flame Retardant (FR) | Very Limited | High Cost & MOQ |

At MTM, we bridge this gap by pre-stocking these materials, eliminating your supply chain risk.

The biggest risk in addressing material shortages is opting for a "local equivalent" without proper validation. Relying solely on a datasheet comparison is a common but dangerous shortcut. Small differences in polymer formulation can lead to significant issues during and after the mold trial.

The ‘Equivalent’ Material Trap

A local material may match the Melt Flow Rate and tensile strength on paper but behave differently under real-world molding conditions. Factors like polymer architecture and additive packages are often not fully disclosed, creating hidden risks that can compromise part integrity.

Beyond the Datasheet

After conducting tests with our clients, we’ve found that unvalidated equivalents can exhibit problems like poor surface finish or dimensional instability. These issues arise from subtle molecular differences. Processes like Chain Scission9 can occur differently, affecting the material’s long-term durability and performance, even if initial tests seem acceptable.

| Validation Step | Validated Equivalent | Unvalidated Equivalent |

|---|---|---|

| Datasheet Review | Matches Key Specs | Matches Key Specs |

| Molding Trial | Predictable Behavior | Unexpected Shrinkage/Warp |

| Part Performance | Meets Design Criteria | Fails Durability Tests |

| Supply Consistency | Reliable Batches | Potential for Variation |

Our role at MTM is to provide either the exact specified grade or a rigorously validated alternative, ensuring your project proceeds without material-related setbacks.

Securing specific Ultradur grades in China is challenging, and using unverified local equivalents introduces significant risk to your project’s timeline and quality. Proper material validation is crucial to avoid costly mold trial failures and ensure product performance meets original design intent.

Case Study Applications: Ultradur in Automotive and E-Mobility Components

In theory, material datasheets are useful. In practice, seeing where a material like Ultradur truly shines is what matters. We see it chosen repeatedly for its reliability in demanding automotive environments, especially for connectors and housings where precision is non-negotiable.

Why Engineers Choose Ultradur

Its selection often comes down to a balance of electrical performance, mechanical strength, and dimensional stability. These factors are critical for parts that must function reliably for years. The material consistently outperforms alternatives in harsh conditions.

Performance in Key Automotive Parts

| Component | Key Requirement | Why Ultradur Excels |

|---|---|---|

| Automotive Connectors | Dimensional Stability | Resists warping, ensuring a secure fit. |

| Sensor Housings | Chemical Resistance | Withstands exposure to automotive fluids. |

| High-Voltage Parts | Electrical Insulation | Maintains high CTI values for safety. |

| Control Unit Cases | Impact Strength | Protects sensitive electronics from shocks. |

Moving beyond standard components, Ultradur is a key material in high-voltage EV applications. These parts face extreme thermal and electrical stress. Competitor materials might offer one strong property but often fail to provide the complete package needed for long-term safety and performance.

High-Voltage Application Challenges

In high-voltage environments, materials must prevent electrical arcing and manage heat effectively. After working with clients on EV component trials, we’ve noted Ultradur’s grades offer superior Dielectric Strength10 and a high Comparative Tracking Index (CTI), which are non-negotiable for safety. This is a clear advantage over some polyamides that can lose insulating properties when they absorb moisture.

Critical Properties for EV Components

At MTM, we help clients source the correct grade of Ultradur for their specific mold trials in China. This ensures their high-voltage parts meet strict performance criteria without delays from international shipping.

| Property | Importance in EV Components | Ultradur’s Advantage |

|---|---|---|

| High CTI | Prevents surface electrical breakdown. | Reduces risk of short circuits. |

| Low Water Absorption | Maintains stable electrical properties. | Ensures consistent insulation performance. |

| Flame Retardancy | Meets UL94 V-0 safety standards. | Critical for battery and charging parts. |

| Thermal Stability | Resists degradation at high temps. | Essential for parts near the powertrain. |

Ultradur’s balanced properties make it a go-to choice for demanding automotive and EV parts, from connectors to high-voltage housings. Its reliability in harsh conditions is a key decision factor for engineers who cannot afford component failure.

Supercharge Your Next Mold Trial: MTM Unlocks Ultradur Mastery

Unlock the full potential of Ultradur grades for your next mold trial in China—without waiting for overseas shipments. Contact MTM now for instant access to pre-stocked PBT materials, expert grade-matching, and rapid delivery that keeps your project on track. Send your RFQ today!

-

Explore how this property influences mold filling, cycle times, and the final quality of your molded parts. ↩

-

This concept helps predict part performance and prevent issues with fiber-reinforced materials. ↩

-

Explore the chemical process behind this material degradation to better inform your design choices. ↩

-

Understand how polymer crystallinity influences shrinkage, warpage, and the mechanical strength of your molded parts. ↩

-

Understanding this metric helps predict material behavior and optimize your molding process. ↩

-

Understanding this thermal decomposition helps select effective flame retardants for high-temperature applications. ↩

-

Explore the microscopic mechanism behind material deformation under long-term stress. ↩

-

Understand how materials deform under long-term stress, crucial for designing durable parts. ↩

-

Learn how polymer degradation affects long-term performance, a crucial factor when evaluating alternative resins. ↩

-

Understand how this property ensures safety and reliability in high-voltage EV systems. ↩