Sourcing Ultramid resin for mold trials in China often becomes a logistics nightmare. Project timelines get derailed when materials sit in customs for weeks, shipping costs spiral out of control, and every delay pushes your prototype schedule further behind.

Ultramid resin solutions are readily available locally in China through pre-stocked suppliers, eliminating import delays and reducing trial costs by up to 60% while maintaining BASF’s original specifications and quality standards.

I’ve worked with engineering teams who’ve seen their mold trial schedules collapse because of material delays. The solution isn’t just about finding any PA6 or PA66 resin – it’s about securing authentic Ultramid grades that match your exact specifications without the overseas shipping headaches.

The Ultimate Guide To Sourcing Ultramid Resin Locally In China

Sourcing Ultramid resin for mold trials in China presents a critical choice: import it or find a local supplier. Importing materials often leads to significant project delays. I have seen teams wait weeks for shipments to clear customs, completely disrupting their trial schedules and pushing back deadlines.

The Problem with Imports

International shipping introduces risks that can halt your project. Customs delays, high freight costs, and logistical headaches are common. A reliable local supply chain for BASF Ultramid sourcing eliminates these variables, ensuring your material is ready when your mold is.

The Local Advantage

A local Ultramid supplier provides speed and reliability. Instead of waiting, you can get materials quickly for your mold trials. This approach significantly reduces lead times and costs associated with international logistics.

| Sourcing Method | Lead Time | Cost Factor | Risk Level |

|---|---|---|---|

| International | 3-6 Weeks | High | High |

| Local (MTM) | 1-3 Days | Low | Low |

Sourcing Ultramid resin in China is more than just a logistical choice; it is a strategic decision. Relying on imports creates a chain of dependencies where a single delay can have a domino effect. Let’s look closer at the typical issues that arise during this process.

Deconstructing Import Delays

First, international freight is unpredictable. Even with premium carriers, shipments can be offloaded or rerouted, adding days or weeks to the transit time. Then comes customs clearance, a process that can be opaque and frustratingly slow, especially for chemical products like engineering resins.

Documentation and Compliance

Every shipment requires perfect documentation. A minor error on a commercial invoice or customs declaration can result in the entire shipment being held for inspection. This not only causes delays but can also lead to fines. Understanding the material’s Rheology1 is also crucial for accurate technical declarations.

This is where a local partner like MTM adds immense value. We handle all sourcing and stocking in advance, so the material is already in China, ready for immediate dispatch. We ensure the correct grade of Ultramid is available for your critical mold trials without any cross-border friction.

| Import Challenge | Local Solution (MTM) |

|---|---|

| Customs Delays | Material already in-country |

| High Shipping Costs | Localized, cost-effective delivery |

| Documentation Errors | No import paperwork needed |

| Unpredictable Transit | Fixed, predictable delivery schedule |

Sourcing Ultramid resin locally in China avoids the risks of international shipping, such as customs delays and high costs. This strategy ensures your mold trial materials are available on time, keeping your project on track and within budget, a core value we provide at MTM.

Complete Breakdown: Ultramid Grades Engineers Should Know

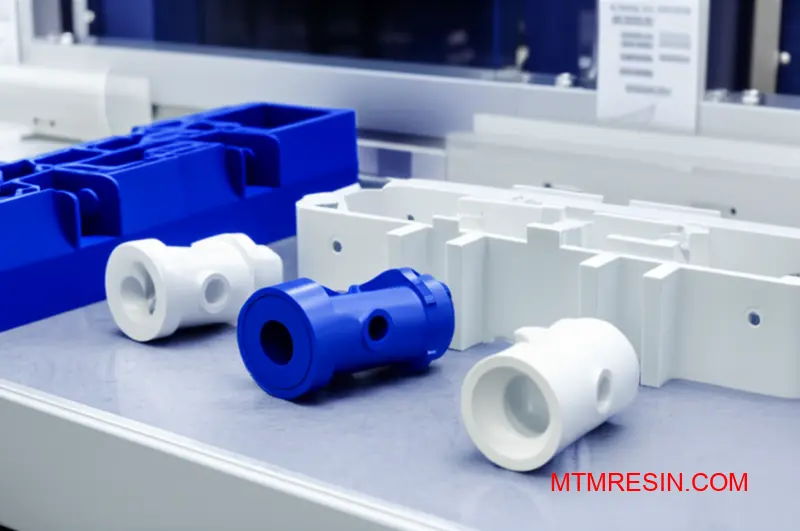

When engineers talk about Ultramid, they’re referring to a large family of materials. The two main types are Ultramid PA6 and PA66. Choosing the right one is critical for a successful mold trial, as their properties differ significantly, impacting everything from strength to surface finish.

Core Ultramid Resin Grades

The grade designation tells you a lot. For example, "A" often indicates a PA66 base, while "B" points to PA6. The numbers and letters that follow specify additives like heat stabilizers or glass fibers. Understanding this code is the first step to material selection.

Key Grade Comparison

We frequently supply these grades for trials. Here’s a quick look at two popular ones.

| Grade | Polymer Base | Key Feature | Common Application |

|---|---|---|---|

| A3EG6 | PA66 | 30% Glass Fiber | Automotive structural parts |

| B3K | PA6 | Unreinforced, good flow | Housings, consumer goods |

Understanding the Details

Selecting the right Ultramid resin grades goes beyond the basics. While A3EG6 offers high stiffness from its glass fiber content, B3K provides an excellent surface finish due to being unreinforced. The choice impacts both the mold design and the final part’s performance.

Beyond the Datasheet

Datasheets provide numbers, but experience tells you the story behind them. For instance, the stiffness of Ultramid A3EG6 properties makes it ideal for under-the-hood components. However, its fibrous nature can affect warp and shrinkage, which must be accounted for during the mold trial.

Processing Considerations

Polyamides like Ultramid are hygroscopic2, meaning they absorb moisture from the air. This moisture can ruin a part during molding. Properly drying the material before a trial is a non-negotiable step we always emphasize to clients to ensure valid results and prevent defects.

Impact of Reinforcement

Let’s look at how reinforcement changes the game. Adding glass fiber significantly alters the material’s behavior.

| Property | Ultramid B3K (Unreinforced) | Ultramid A3EG6 (30% GF) |

|---|---|---|

| Tensile Modulus | Lower | Significantly Higher |

| Impact Strength | Higher | Lower (more brittle) |

| Surface Finish | Excellent | Good (fiber may show) |

| Shrinkage | Isotropic | Anisotropic |

This is why a trial with the exact specified grade is so important. At MTM, we stock these specific Ultramid grades in China so your trial reflects real-world production conditions without delay.

Choosing the right Ultramid grade is crucial. It requires balancing mechanical needs, processing demands, and final part aesthetics. Understanding the differences between base polymers like PA6 and PA66, along with the effects of additives, ensures a successful and predictive mold trial.

How To Validate Ultramid Resin Equivalents Without Compromise

Choosing an Ultramid equivalent resin requires a structured validation process, not just a datasheet comparison. Skipping this step introduces risks that can delay your project and compromise part quality. At MTM, we guide clients through this verification to ensure performance is never sacrificed for availability.

Key Performance Indicators

Focus on critical properties beyond the basics. While melt flow and density are important, you must also consider mechanical strength, thermal stability, and shrinkage rates. These factors directly impact the final part’s performance and dimensional accuracy.

Initial Data Comparison

| Property | Original Ultramid | Equivalent Resin | Tolerance |

|---|---|---|---|

| Tensile Strength (MPa) | Specification Value | Test Value | +/- 5% |

| Flexural Modulus (GPa) | Specification Value | Test Value | +/- 5% |

| HDT @ 1.8 MPa (°C) | Specification Value | Test Value | +/- 3°C |

The Data Sheet Deep Dive

Your validation starts with a side-by-side technical data sheet (TDS) review. Don’t just glance at the numbers. Look for similarities in filler content, grade type (e.g., glass-filled, flame retardant), and processing temperature windows. This initial screening helps filter out unsuitable candidates immediately.

Practical Mold Trial Testing

A datasheet match is only theoretical. The real proof is in the mold. We recommend a short run using the Ultramid alternative validation material. During this trial, monitor injection pressure, cycle time, and part ejection behavior closely. Any significant deviation signals a processing mismatch.

Post-Processing Evaluation

After molding, the parts need careful inspection. Measure critical dimensions to check for warpage or shrinkage differences. Also, perform basic functional tests relevant to the part’s application. Key metrics like the Tensile Modulus3 must align with the original BASF replacement resin specifications to ensure structural integrity.

| Test Phase | Key Metric | Acceptance Criteria |

|---|---|---|

| Molding | Cycle Time | Within 5% of original material |

| Post-Mold | Dimensional Stability | Critical dimensions within tolerance |

| Functional | Load Bearing | No failure under standard test |

Validating an Ultramid equivalent is a multi-step process. It moves from data sheet analysis to practical mold trials and part inspection. This methodical approach is the only way to confirm a replacement resin meets your project’s strict performance and quality standards without compromise.

Speed Vs. Safety: Choosing Ultramid Resin Under Tight Deadlines

When project deadlines are tight, every decision feels amplified. The pressure to get a mold trial running can lead to compromises, especially in material selection. Choosing the right Ultramid resin grade becomes a battle between moving fast and ensuring complete accuracy for the final product.

The Urgency Trap

Rushing this choice often means accepting a "good enough" substitute. However, this approach introduces significant risks. An incorrect grade can invalidate the entire trial, leading to more delays and costs than waiting for the correct material in the first place. The key is to find a faster path to the right material.

Balancing Speed with Precision

A reliable local supplier changes the equation. With pre-stocked materials, you avoid international shipping delays and customs hurdles. This allows you to meet urgent deadlines without sacrificing material integrity. It is the safest way to accelerate your project schedule.

| Sourcing Method | Typical Lead Time | Risk Factor |

|---|---|---|

| Standard Overseas Order | 4-8 Weeks | High (Delays, Customs) |

| Expedited Local Stock | 1-3 Days | Low (Immediate Availability) |

The real challenge isn’t just speed; it’s maintaining material fidelity under pressure. Choosing a substitute Ultramid grade, even one with a similar-looking datasheet, can undermine the entire validation process. Subtle differences in formulation have significant real-world consequences during a mold trial.

The Hidden Costs of Compromise

I have seen projects derailed by a seemingly minor material deviation. A substitute might have a different melt flow, shrinkage rate, or even a slight color variation that makes the trial results unreliable. This forces expensive re-trials, completely negating any time saved initially. This is why fast sourcing Ultramid must also mean sourcing the exact grade.

Material Integrity is Non-Negotiable

A safe quick mold trial resin is one that perfectly matches your specification. Factors like Crystallinity4, which affects part shrinkage and strength, cannot be ignored. At MTM, we provide Ultramid resin fast delivery from our China-based stock, ensuring you get the specified material without the wait.

| Rushed Decision | Potential Consequence | Long-Term Impact |

|---|---|---|

| Using "Similar" Grade | Incorrect Shrinkage | Part Dimensional Failure |

| Ignoring Fillers/Additives | Weak Mechanical Properties | Product Field Failure |

| Overlooking Flow Rate | Mold Filling Issues | Wasted Trial Time & Cost |

When facing a tight deadline, the choice between speed and safety is critical. Opting for a locally stocked, specified Ultramid resin eliminates this conflict. It ensures your mold trial is both fast and accurate, protecting your project from costly delays and rework.

How Engineers Can Test Ultramid Properties At Prototype Stage

Validating Ultramid properties at the prototype stage is critical. Getting it right prevents costly changes later. Engineers must confirm that the material behaves as expected in the actual mold, not just on a datasheet. This ensures the final product meets performance specifications from day one.

Key Validation Tests

Early testing focuses on mechanical performance. We primarily look at strength, flow, and durability. These tests give a clear picture of how the part will function in its intended environment, which is crucial for high-performance applications using Ultramid.

Common Testing Methods

| Test Type | Objective | Key Metric |

|---|---|---|

| Tensile Test | Measures strength under tension | Ultimate Tensile Strength (MPa) |

| Impact Test | Assesses toughness | Izod or Charpy (J/m) |

| Flow Analysis | Predicts mold filling behavior | Melt Flow Rate (g/10 min) |

When your mold is in China, using a locally sourced Ultramid sample for your mechanical validation mold is the most efficient path. This eliminates shipping delays and customs issues, allowing you to get reliable data faster. I always advise teams to focus on these core tests first.

Tensile and Impact Strength

Tensile testing pulls a sample part until it breaks, revealing its ultimate strength and elongation. For Ultramid parts, this confirms it can handle expected loads. Impact testing, like Izod, shows how the part withstands sudden shocks, a vital property for components in automotive or industrial gear.

Analyzing Molding Flow

Molding flow isn’t just about filling the cavity. It also affects the internal stress and molecular orientation of the polymer, which influences the part’s final strength. Inconsistent flow can lead to weak points. This is where Anisotropy5 becomes a critical factor in part performance evaluation.

Test Comparison for Prototypes

| Test | What It Tells You | Why It’s Important |

|---|---|---|

| Tensile Strength | How the part resists being pulled apart. | Confirms load-bearing capacity. |

| Impact Resistance | How the part handles sudden force. | Prevents failure from drops or shocks. |

| Flow Simulation | How easily the resin fills the mold. | Predicts weld lines and cosmetic defects. |

By conducting these tests on prototype parts molded with the final grade of Ultramid, you gain confidence in your design and material selection before committing to mass production.

Effective prototype testing of Ultramid requires the right mechanical validation with consistent, locally sourced materials. This approach ensures your final product meets design specifications and helps you avoid significant delays and costs by verifying performance early in the process.

Insider Tips For Verifying Authenticity Of Ultramid In China

Sourcing genuine BASF Ultramid in China requires careful attention. Using substitute materials, even unknowingly, can lead to failed trials and significant project delays. Your procurement strategy must go beyond price comparison to ensure material integrity and protect your timelines.

Key Verification Pillars

Focusing on documentation, traceability, and supplier reputation is crucial. These three areas provide a solid framework for confirming you are receiving authentic Ultramid. A systematic check reduces risk significantly.

Initial Checks for Procurement Teams

A quick checklist can help you screen potential suppliers effectively from the start.

| Verification Area | What to Check | Red Flag |

|---|---|---|

| Documentation | Certificate of Analysis (COA) | Missing or generic data |

| Traceability | Batch Number | Untraceable or repeated numbers |

| Supplier | Official Authorization | Unwilling to share credentials |

A genuine BASF Certificate of Analysis is your first line of defense. It contains specific property values, not just ranges. Based on our work with clients, we always cross-reference key metrics like tensile strength and the Melt Flow Index6. These values should match BASF’s official technical datasheets for that specific grade of Ultramid.

The Importance of Batch Tracking

Every bag of authentic Ultramid has a unique batch number. This number is your link back to the production facility. A reliable supplier can provide traceability documentation connecting your purchase to a specific production run. Be wary of suppliers who cannot provide this.

Supplier Screening and Due Diligence

Vetting your supplier is as important as checking the material itself. A legitimate distributor will be transparent about their relationship with BASF and have a history of supplying authentic engineering plastics. Avoid suppliers who primarily deal in generic or unbranded materials.

| Supplier Type | Characteristics | Risk Level |

|---|---|---|

| Authorized Distributor | Direct link to BASF, full traceability | Low |

| Reputable Trader | Known in the industry, can provide proof | Medium |

| Unknown Source | Vague answers, generic paperwork | High |

Verifying genuine Ultramid is about a multi-step process. Scrutinize the Certificate of Analysis, demand full batch traceability, and thoroughly vet your supplier. This diligent approach ensures material authenticity and safeguards your mold trial success in China.

Streamlining Communication Between Molder, Material, And OEM Teams

Fragmented communication often creates delays and misunderstandings in molding projects. When the OEM, molder, and material supplier operate in separate silos, critical information gets lost. This misalignment can lead to incorrect material orders, production halts, and budget overruns, disrupting the entire project timeline.

Common Communication Gaps

Each team has different priorities, which can lead to friction. The key is to find a common ground where information flows freely. Without a central point of contact, coordinating details becomes a significant challenge for everyone involved.

Who is Responsible for What?

A clear definition of roles prevents confusion. Delays often happen when one party is waiting for information or approval from another.

| Team | Primary Concern | Communication Challenge |

|---|---|---|

| OEM | Final Part Quality & Timeline | Relaying exact specs to suppliers |

| Molder | Tooling & Process Efficiency | Getting correct material on time |

| Material Supplier | Resin Availability & Logistics | Coordinating delivery with molder’s schedule |

This separation makes it difficult to manage the process effectively. A unified approach is essential for success.

The Central Partner Advantage

A central supply partner, like MTM, acts as the bridge connecting these teams. We simplify the complex web of interactions by becoming the single point of contact for all material-related matters. This is especially crucial for centralized resin sourcing in China.

This model streamlines the entire process. Instead of three separate conversations, the OEM and molder have one channel for securing the right materials, such as specific Ultramid grades. This improved Ultramid supplier coordination eliminates costly errors and saves valuable time.

Ensuring Specification Uniformity

One of our primary roles is to guarantee the correct material is used. We ensure the resin, like Ultramid, meets the exact specifications required by the OEM. This involves meticulous Material Traceability7 from sourcing to delivery, which is fundamental for consistent part performance and quality control.

The table below contrasts the traditional supply method with our centralized approach, highlighting the benefits for both molder and OEM resin supply.

| Aspect | Traditional Model | Centralized Partner Model (MTM) |

|---|---|---|

| Communication | Multiple, fragmented channels | Single point of contact |

| Material Sourcing | OEM or molder manages logistics | Pre-stocked, locally available |

| Spec Verification | Risk of miscommunication | Guaranteed spec uniformity |

| Lead Time | Weeks, plus customs delays | Days, immediate availability |

This simplified structure ensures the molder gets the right material quickly, allowing them to focus on the tool trial.

A central supply partner minimizes friction by managing resin availability, specification uniformity, and logistics. This integrated approach ensures all teams are aligned, preventing delays and guaranteeing that mold trials proceed smoothly with the correct materials like Ultramid.

Top Questions Engineers Ask Before Approving Ultramid For Mold Trials

Engineers often focus on key technical data before approving Ultramid for mold trials. They need to ensure the material performs as expected in both the mold and the final part. My team frequently fields questions about processing stability and part performance, forming a crucial engineer resin checklist.

Material Performance Validation

The primary concern is whether the chosen Ultramid grade meets the part’s mechanical requirements. Engineers scrutinize data sheets for tensile strength, impact resistance, and long-term durability. These values must align perfectly with the design specifications to prevent premature failures.

Key Processing Parameters

Validating processing behavior is equally important. Key questions revolve around melt flow, shrinkage rates, and required drying times. This information is critical for accurate mold design and process setup.

| Concern Area | Key Question | Why It Matters |

|---|---|---|

| Flow Behavior | What is the recommended melt temperature? | Affects mold filling, surface finish, and cycle time. |

| Shrinkage | What is the expected shrinkage rate? | Critical for dimensional accuracy of the final part. |

| Thermal Stability | How does it perform at high temperatures? | Determines suitability for under-the-hood or electronic parts. |

A deep dive into the Ultramid technical FAQ for molds reveals more specific concerns. For instance, engineers don’t just ask about shrinkage; they ask about anisotropic shrinkage. This is especially relevant for fiber-reinforced grades, where fibers align with flow, causing different shrinkage rates along different axes.

Thermal Resistance in Detail

Thermal resistance isn’t just one number. Engineers need to understand both short-term heat deflection temperature (HDT) and long-term continuous use temperature. These criteria determine if an Ultramid part can survive heat spikes and function reliably over its intended lifespan without degrading. We often help clients analyze these points in detail.

Validating Flow for Complex Geometries

For parts with thin walls or complex features, flow behavior is paramount. An engineer might ask for simulation data or practical examples. After working with clients on similar projects, we’ve found that proper gate design and injection speed are crucial for Ultramid to fill these features correctly, avoiding defects like weld lines or short shots. The material’s Glass Transition Temperature8 also influences its behavior during and after molding.

A successful Ultramid approval process depends on verifying key technical properties like flow, shrinkage, and thermal resistance. This diligence ensures the material meets both processing and end-use performance requirements, preventing costly delays and part failures during production.

Choosing The Right PA6 Or PA66 Resin: Ultramid Decision Framework

Choosing between Ultramid PA6 and PA66 often comes down to three key project requirements: structural, aesthetic, or thermal. Each material offers distinct advantages. Making the wrong choice can compromise part performance or increase costs unnecessarily. This guide helps you navigate the decision.

Structural vs. Aesthetic Needs

For applications demanding high strength and stiffness, PA66 is typically the better option. Its crystalline structure provides superior mechanical properties. Conversely, PA6 offers a better surface finish, making it ideal for parts where appearance is critical. This is a common trade-off we discuss with clients.

Thermal Performance

If your component operates at elevated temperatures, PA66 is the clear winner. It has a higher melting point and better thermal stability. We often recommend specific Ultramid grades based on heat exposure.

Here is a quick comparison to guide your initial selection.

| Requirement | Preferred Ultramid | Key Benefit |

|---|---|---|

| Structural | PA66 | Higher stiffness and strength |

| Aesthetic | PA6 | Superior surface finish |

| Thermal | PA66 | Higher heat resistance |

When you get into specific Ultramid grades, the choice becomes more nuanced. We need to look beyond the base polymer and consider the impact of reinforcements like glass fibers. This is where a clear understanding of your end-use application is crucial.

Deeper Dive into Ultramid Selection

For structural parts, an Ultramid PA66 grade with glass fiber reinforcement provides excellent rigidity and creep resistance. It is often specified for automotive engine components or industrial machinery parts. The higher stiffness ensures dimensional stability under load, a critical factor for many engineering designs.

Aesthetic components, such as consumer product housings, benefit from the smooth, glossy surface of Ultramid PA6. It processes more easily and results in fewer surface imperfections. This can reduce post-processing steps and associated costs, an important consideration during mold trials.

Temperature as the Deciding Factor

For thermal requirements, the conversation often shifts to the material’s Heat Deflection Temperature (HDT)9. Ultramid PA66 consistently outperforms PA6 in this area. Our tests with clients confirm that even unreinforced PA66 maintains its shape better at higher temperatures than its PA6 counterpart.

| Application Focus | Ultramid Grade Example | Why It Works |

|---|---|---|

| High-Load Mechanical | A3WG6 (PA66, 30% GF) | Maximum stiffness and strength |

| Visually Critical Part | B3S (PA6) | Excellent surface quality |

| High-Temp Environment | A3HG5 (PA66) | Enhanced thermal stability |

Having both PA6 and PA66 Ultramid grades ready in our China warehouse allows our clients to test these options back-to-back, confirming their material choice without international shipping delays.

Choosing between Ultramid PA6 and PA66 involves balancing performance, aesthetics, and cost. PA66 excels in structural and thermal applications, while PA6 offers superior surface finish for aesthetic parts. A clear understanding of your primary requirement is key to making the correct selection.

Choose MTM for Ultramid Resin—Faster Mold Trials, Zero Delays

Ready to accelerate your next mold trial with authentic Ultramid resin, right here in China? Contact MTM today—get instant quotes, verified material stock, and expert support for every Ultramid grade and equivalent. Let’s keep your project on schedule: send your inquiry now and power your mold trial with MTM!

-

Understand how this property impacts material processing and final part quality. ↩

-

Learn how moisture absorption affects polyamide parts’ dimensional stability and strength. ↩

-

Learn how this core property measures material stiffness, a key factor in structural application performance. ↩

-

Understanding this helps predict a material’s shrinkage, stiffness, and chemical resistance, which is crucial for accurate trial outcomes. ↩

-

Understanding this concept helps predict part weakness and optimize mold design for material flow. ↩

-

Learn how this single value can be a powerful indicator of polymer grade, quality, and potential adulteration. ↩

-

Learn how tracking materials from source to final part ensures quality and compliance in your projects. ↩

-

Understanding this property helps predict material behavior at elevated service temperatures. ↩

-

Understanding this value helps predict a part’s stability in high-temperature operating environments. ↩